Device for preventing welding deformation of annular V groove stabilizer and use method of device for preventing welding deformation of annular V groove stabilizer

A welding deformation and stabilizer technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of ring V-groove stabilizer deformation and inability to correct, so as to prevent oxidation, solve out-of-tolerance problems, and avoid a large number of corrections The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

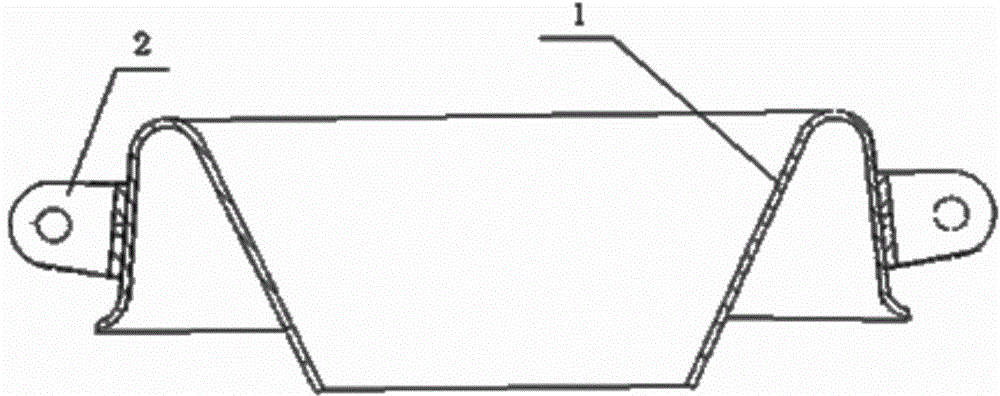

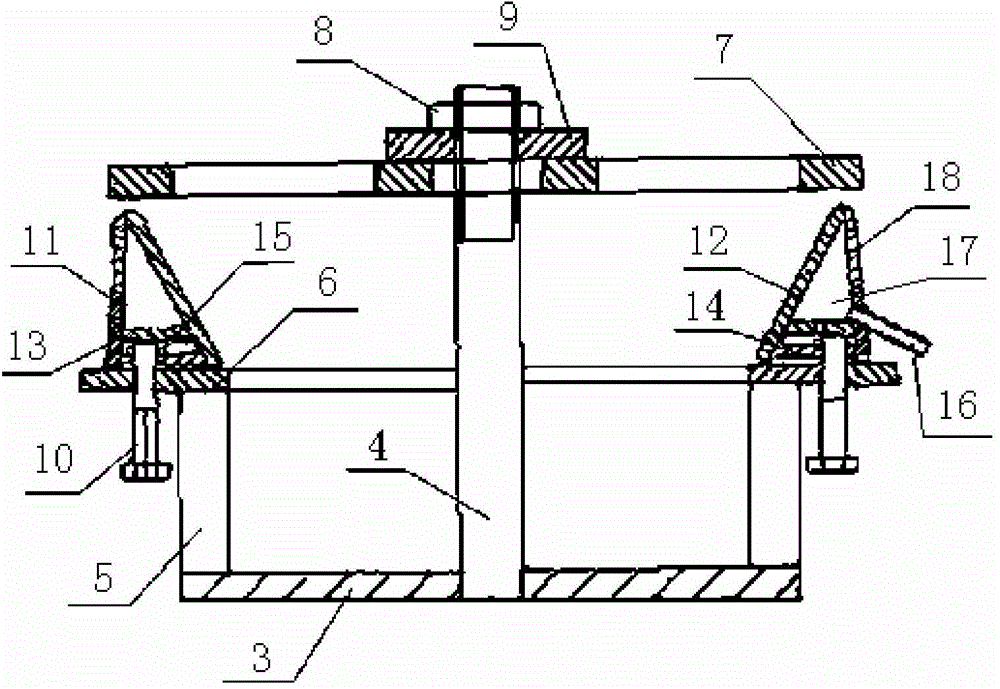

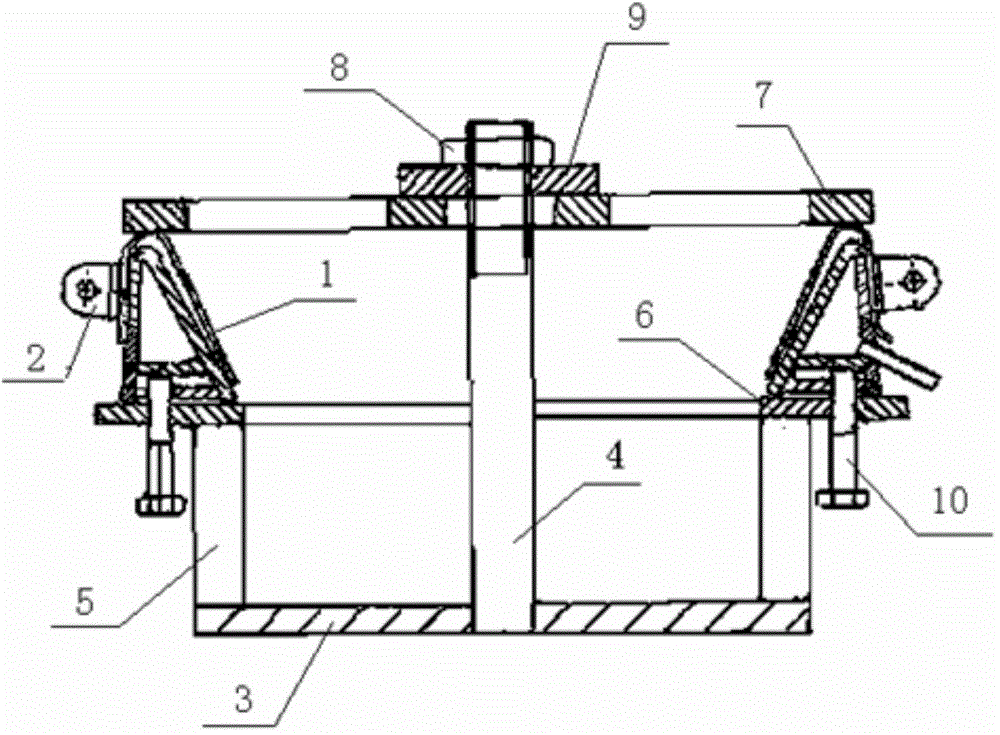

[0027] Such as figure 2 As shown, a device for preventing welding deformation of an annular V-groove stabilizer includes a supporting and compressing structure, a moving pressing structure and a ventilation protection structure; the supporting and compressing structure includes a base 3, a column 5, a mandrel 4, and a support plate 6. Gland 7 and compression nut 8, the mandrel 4 is fixed on the center of the base 3, the column 5 is fixed on the periphery of the base 3, and the support plate 6 is fixed on the column 5, a round hole is set in the center of the gland 7, the mandrel 4 can pass through the hole, the compression nut 8 is threadedly connected with the mandrel 4, the gland 7 and the compression An open backing ring 9 is arranged between the tightening nuts 8; the moving tightening structure includes a push rod 10 and a bulging tire, the bulging tire is composed of an inner wall 12, an outer wall 11 and a bottom plate 13, and the shape of the bulging tire is stable wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com