Ribbon retainer sizing matrix machining technology

A processing technology and cage technology, which is applied in the field of processing technology of wave-shaped cage shaping concave die, can solve the problems of large production demand of shaping die and concave die, complex processing technology, long production cycle, etc. , The effect of good luminosity and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The manufacturing process of the cage shaping die according to the present invention, the process steps are as follows:

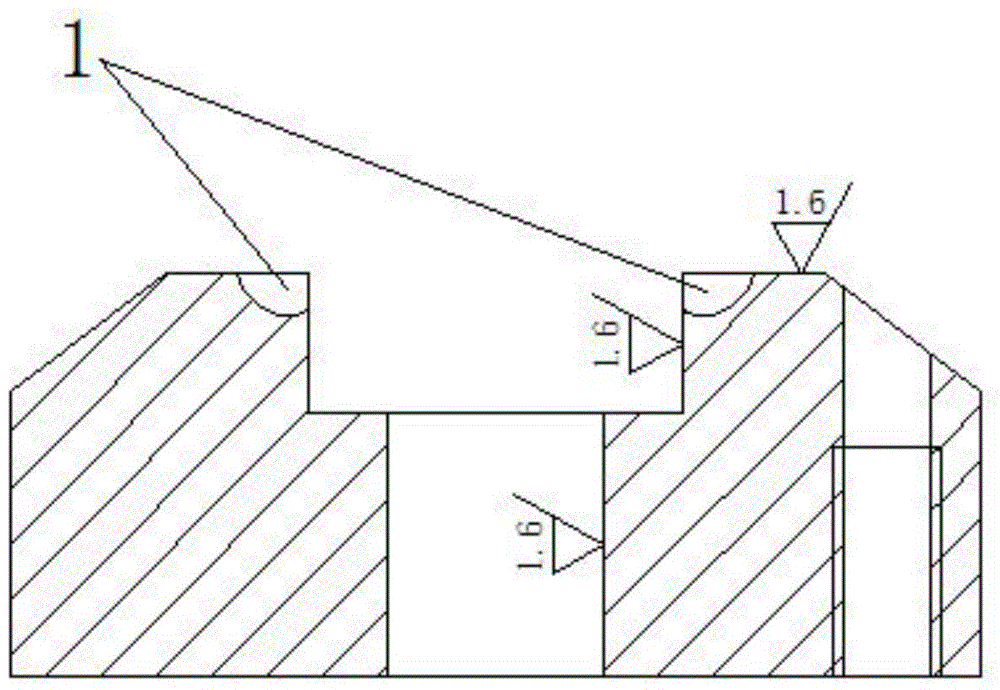

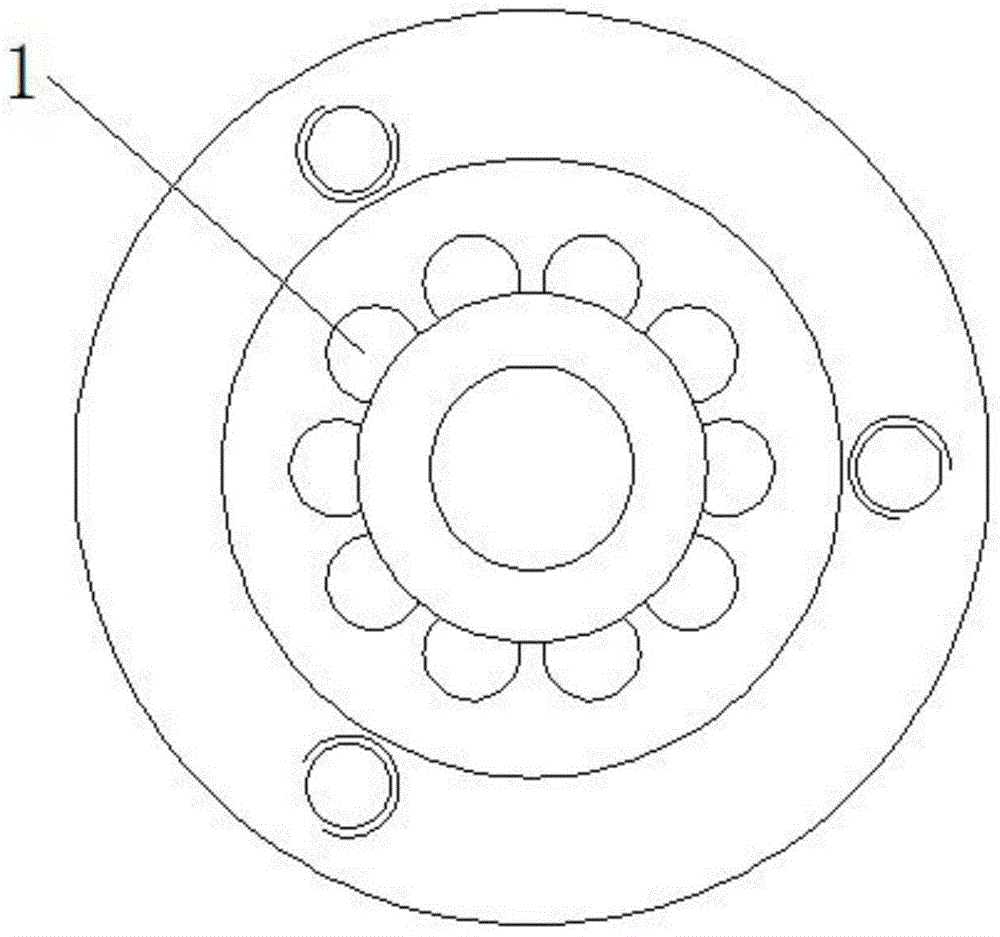

[0028] (1) Drawing: Draw the mold drawing, as attached figure 1 , 2 The drawing of the corrugated cage shaping die is shown.

[0029] (2) Material preparation: preparing a blank, which is a cylindrical blank for injection molding.

[0030] (3) Turning: According to the drawings, except for the amount of grinding left on each side of Ra1.6, the inner diameter of the seam is formed by subtracting 6mm from the center diameter of the socket, and the rest are formed according to the drawings.

[0031] (4) Flat grinding: softly grind the two planes, leaving 0.3 mm for fine grinding.

[0032] (5) Milling and boring machining center: process each equally divided ball socket, ensure that the position and center are within 0.01mm, drill and tap; there are 10 ball sockets, distributed in 10 equal parts around the central axis.

[0033] (6) Tur...

Embodiment 2

[0041] Embodiment 2: The manufacturing process of the cage shaping die according to the present invention, the process steps are as follows:

[0042] (1) Drawing: Draw the mold drawing, as attached figure 1 , 2 The drawing of the corrugated cage shaping die is shown.

[0043] (2) Material preparation: preparing a blank, which is a cylindrical blank for injection molding.

[0044] (3) Turning: According to the drawings, except for the amount of grinding left on each side of Ra1.6, the inner diameter of the seam is formed by subtracting 6mm from the center diameter of the socket, and the rest are formed according to the drawings.

[0045] (4) Flat grinding: softly grind the two planes, leaving 0.35 mm for fine grinding.

[0046] (5) Milling and boring machining center: Process each equally divided ball socket, ensure that the position and center are at 0.02mm, drill and tap; there are 10 ball sockets, distributed in 10 equal parts around the central axis.

[0047] (6) Turner...

Embodiment 3

[0055] Embodiment 3: The manufacturing process of the cage shaping die according to the present invention, the process steps are as follows:

[0056] (1) Drawing: Draw the mold drawing, as attached figure 1 , 2 The drawing of the corrugated cage shaping die is shown.

[0057] (2) Material preparation: preparing a blank, which is a cylindrical blank for injection molding.

[0058] (3) Turning: According to the drawings, except for the amount of grinding left on each side of Ra1.6, the inner diameter of the seam is formed by subtracting 6mm from the center diameter of the socket, and the rest are formed according to the drawings.

[0059] (4) Flat grinding: softly grind the two planes, leaving 0.4 mm for fine grinding.

[0060] (5) Milling and boring machining center: Process each equally divided ball socket, ensure that the position and center are at 0.02mm, drill and tap; there are 10 ball sockets, distributed in 10 equal parts around the central axis.

[0061] (6) Turner:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com