Deformation polishing process and polishing clamp for 2.5D window screen

A special-shaped, window technology, applied in the direction of manufacturing tools, grinding/polishing equipment, surface-polished machine tools, etc., can solve problems affecting product processing and process needs, economic losses of production enterprises, workpiece processing failures, etc. efficiency, increase productivity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the 2.5D window screen special-shaped polishing process will be described below with reference to the accompanying drawings.

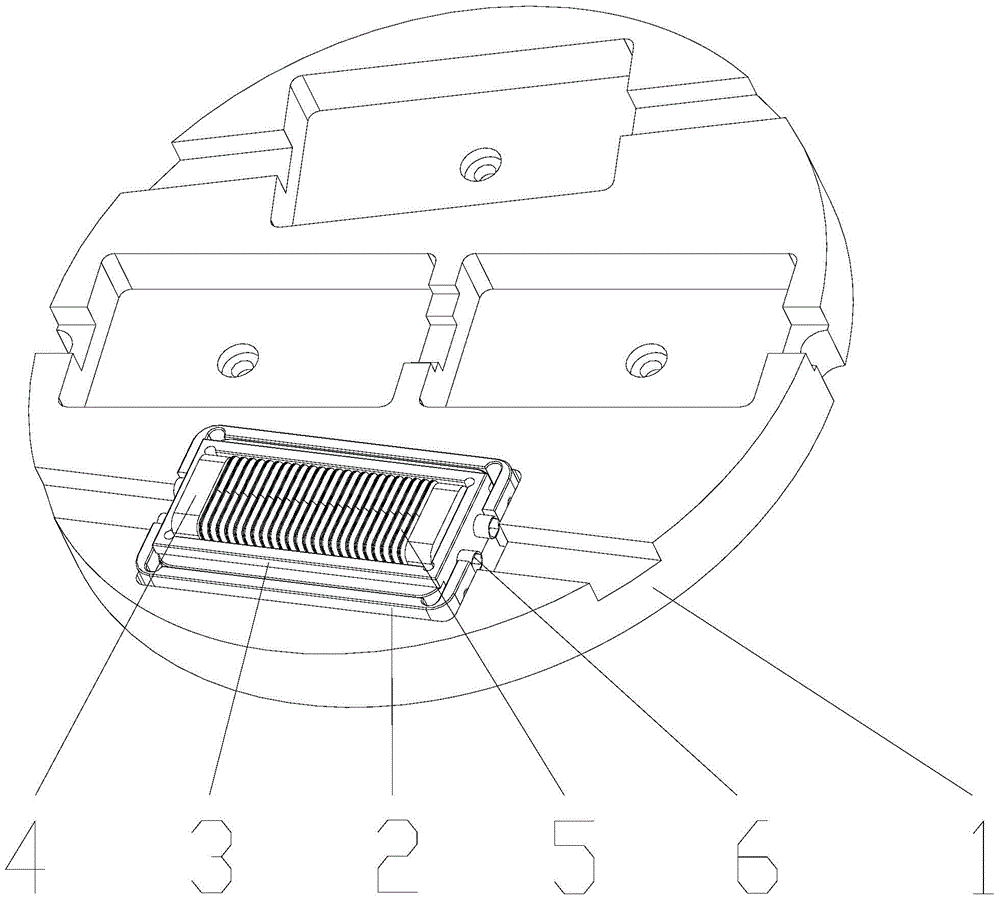

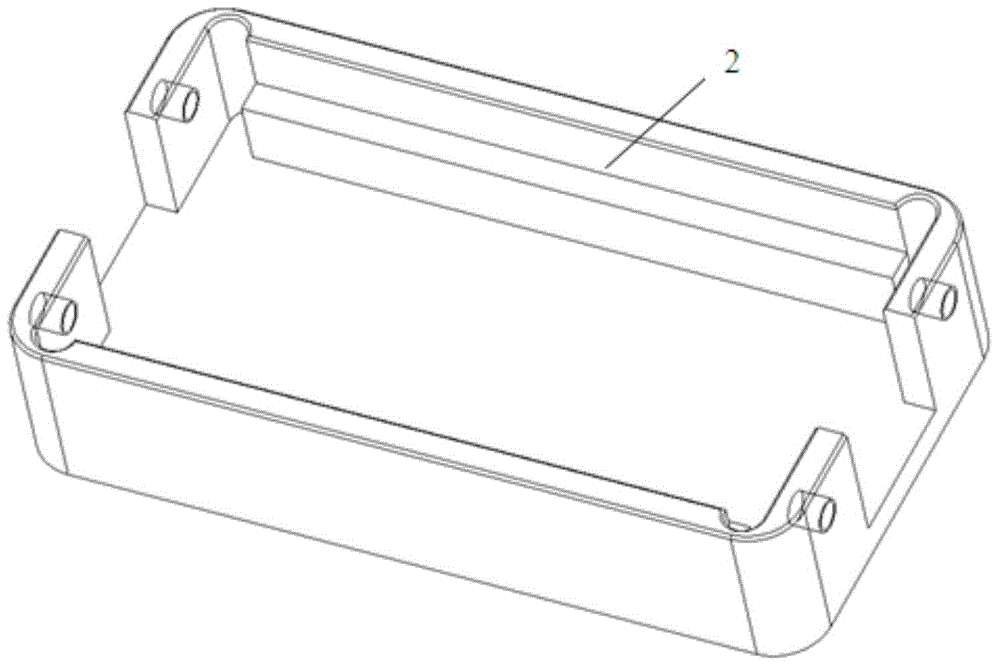

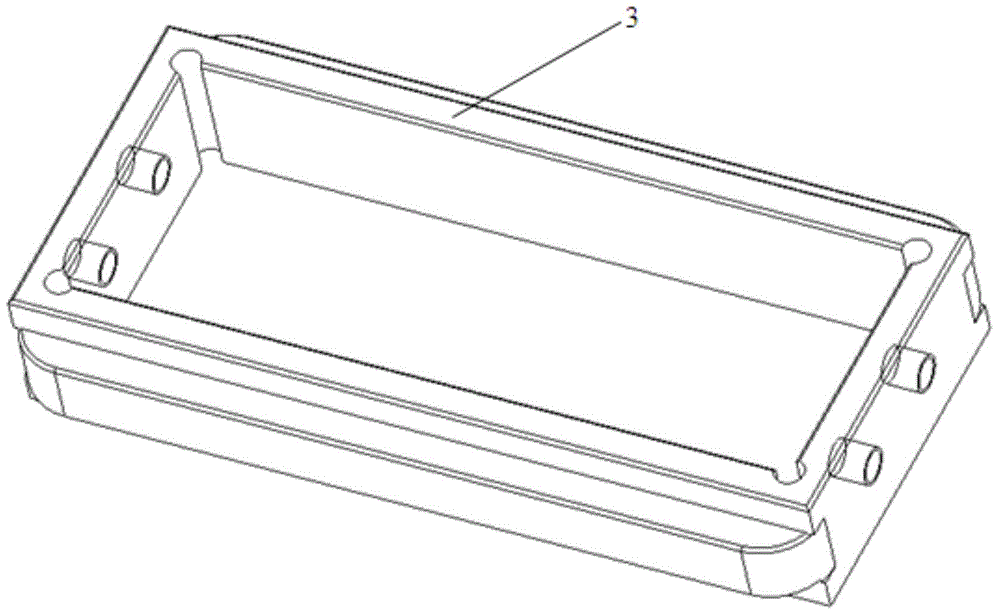

[0027] Such as figure 1 with image 3 As shown, a 2.5D window screen special-shaped polishing fixture includes a hollow box body with upper and lower openings, the middle of the box body is a product placement groove, the width of the product placement groove is not less than the length of the product, and the thickness of the box body Less than the width of the product, the box body is provided with screw holes matched with the jack screws 6 on opposite sides.

[0028] A 2.5D window screen special-shaped polishing process, including the following steps

[0029] a. Product stacking:

[0030] Such as Figure 4 As shown, the 2.5D face 2.5D face and the 2D face 2D face of the product 5 are stacked in sequence, and then the stacked products are placed in the fixture 3, and the two ends of the stacked products are pressed tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com