Dust removing system for wood platy parts

A technology for cleaning system and plate-shaped parts, which is applied in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problem of poor cleaning effect, inability to clean small particles, and affect the quality of spraying processing and other issues to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

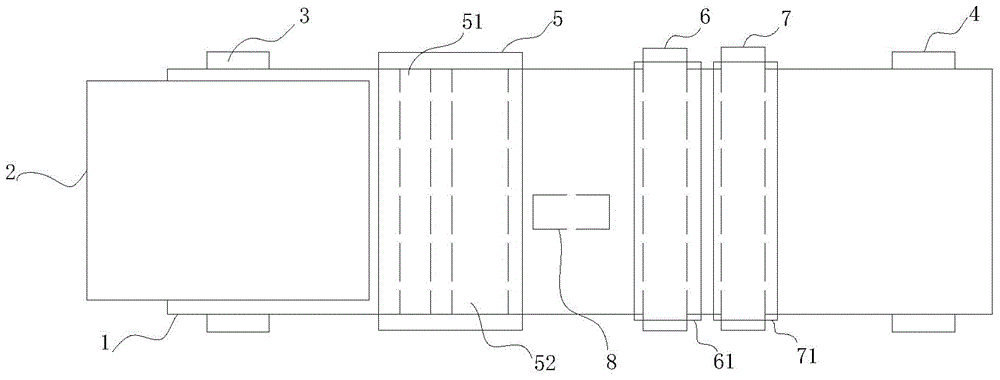

[0010] Example. A kind of dust removal system for wooden board type parts, constituted as figure 1 As shown, it includes a frame, a conveyor belt 1, a main drive roller 3 arranged at both ends of the conveyor belt 1 and a brush roller arranged on the top of the conveyor belt 1, the main drive roller 3 and the brush roller are connected to a drive motor, and the frame The bottom surface is provided with vibration motor 8. The top of the conveyor belt 1 is provided with a dust collection cover 5 in front of the brush roller, and the mouth of the dust collection cover 5 is close to the plank 2. The dust collection cover 5 is a cube with a hollow bottom, and the section along the direction of movement of the plank 2 is rectangular. The sides are larger than the width of the plank. The dust collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com