Mold locking mechanism of dual-mold vulcanizing machine

A technology of machine lock and locking groove, which is applied in the field of clamping mechanism of double-mode vulcanizing machine, which can solve the problems of affecting locking precision, mold falling off, and many moving parts, and achieves easy installation and debugging, not easy to bend and deform, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

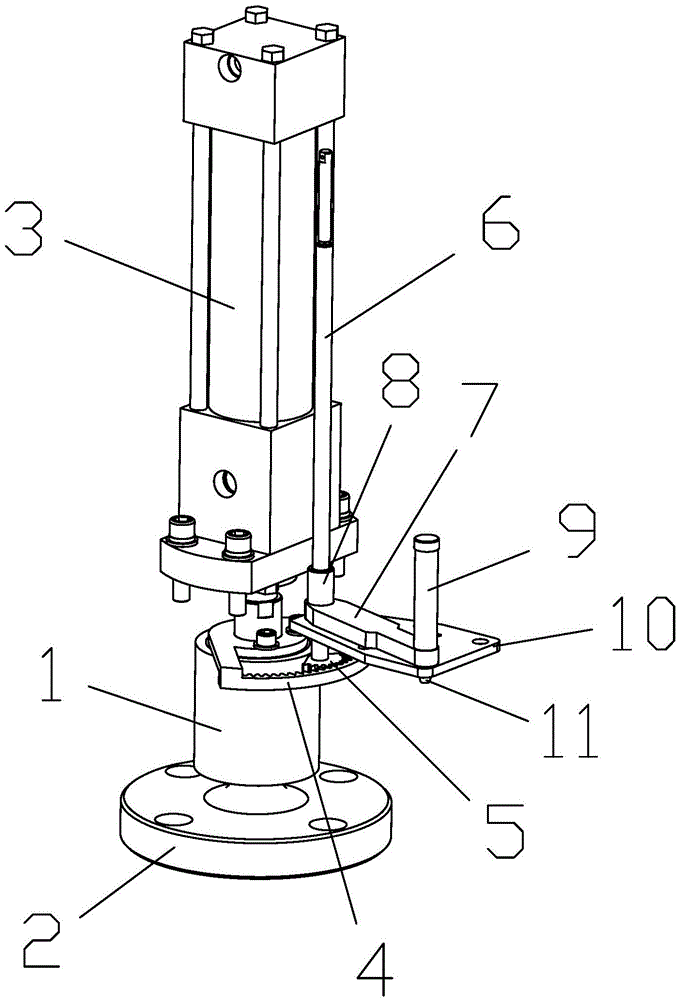

[0009] The clamping mechanism of the double-mode vulcanizer of the present invention, such as figure 1 As shown, it includes a cross slot seat 1 and a cross chuck 2, the mold is fixed on the cross chuck 2, the bottom of the cross slot seat 1 is provided with a cross-shaped locking groove, and the top of the cross chuck 2 is provided with a top ten Glyph-shaped locking column, the top of the locking column can be inserted into the locking groove, and the top of the locking column is clamped in the locking groove through the mutual rotation between the cross groove seat 1 and the cross chuck 2, and the vulcanizing machine is used for lifting the mold. The piston rod of hydraulic cylinder 3 links to each other with cross groove seat 1.

[0010] The clamping mechanism also includes a sector-shaped internal gear 4, a sector-shaped external gear 5, a guide shaft 6, and a toggle lever 7. The sector-shaped internal gear 4 is fixed on the cross recessed seat 1, the sector-shaped extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com