Taking/putting locking mechanism suitable for packaging consumables

A technology of locking mechanism and consumables, which is applied in printing and other fields, and can solve problems such as low efficiency and inconvenient operation of ribbon cassettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

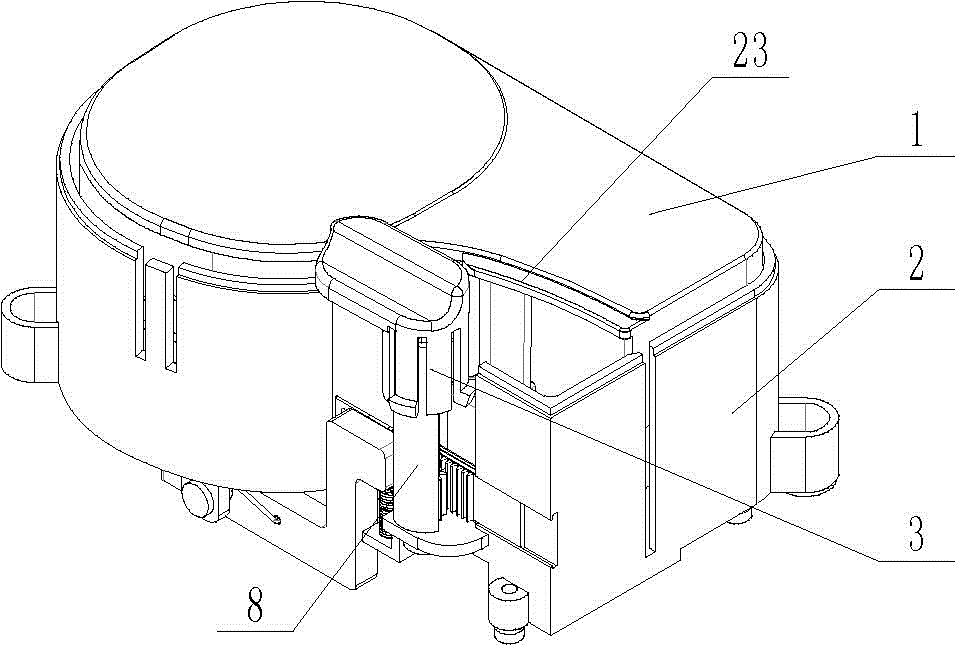

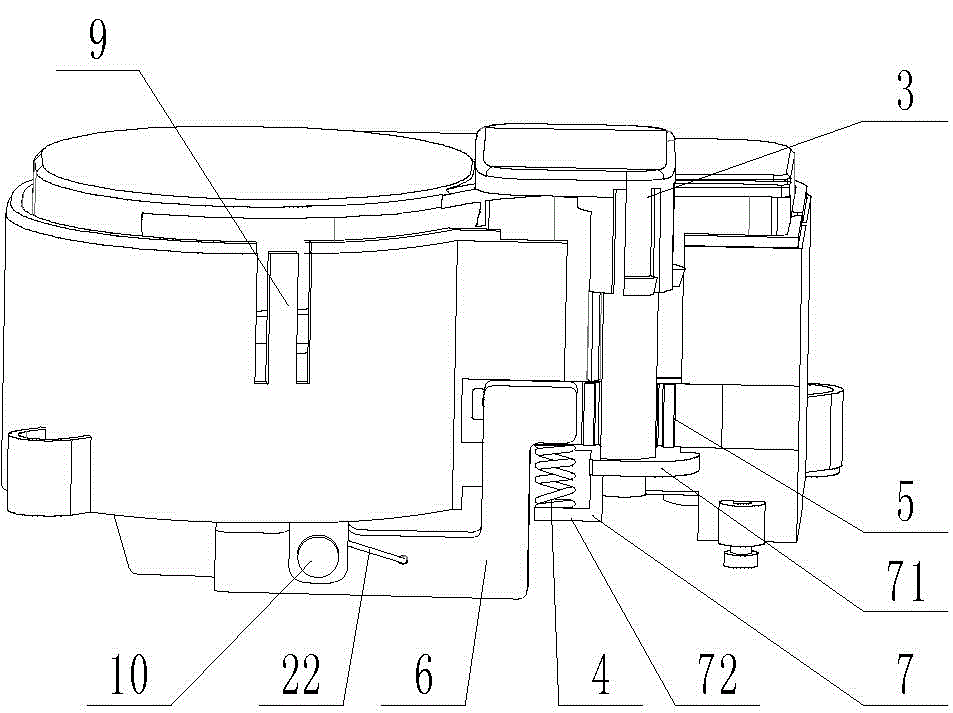

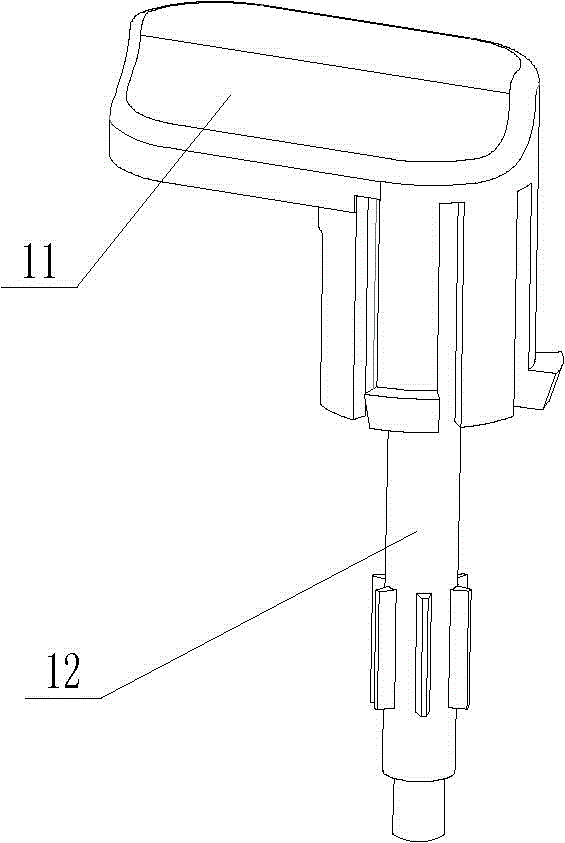

[0024] like figure 1 and figure 2 As shown, the present invention is a pick-and-place locking mechanism suitable for packaging consumables, including a ribbon cassette 1, a ribbon cassette base 2, a locking lever 3, a compression spring 4, a rack 5 and a push rod 6, and the ribbon There is a pit on the cassette base 2, the ribbon cassette 1 is located in the pit, the ejector rod 6 is located under the base 2 of the ribbon cassette, a slot is provided on the base 2 of the ribbon cassette, and the rack 5 is located in the slot. A stepped support plate 7 is provided below the slot of the ribbon cassette base 2 , and the pressure spring 4 is located between the push rod 6 and the stepped support plate 7 . The stepped support plate 7 includes an upper step 71 and a lower step 72, the upper step 71 is provided with a support pipe 8 and a counterbore, and the lower step 72 is provided with a first positioning connection block. The locking rod 3 is detachably connected with the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com