Multi-point electric control goods bundling device for vehicle

A binding device and multi-point technology, which is applied in the direction of motor vehicles, vehicles used for freight transportation, and parts of binding machinery, etc., can solve the problems of high labor intensity, low work efficiency, and scattered goods, and achieve improved binding Efficiency, efficiency improvement, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

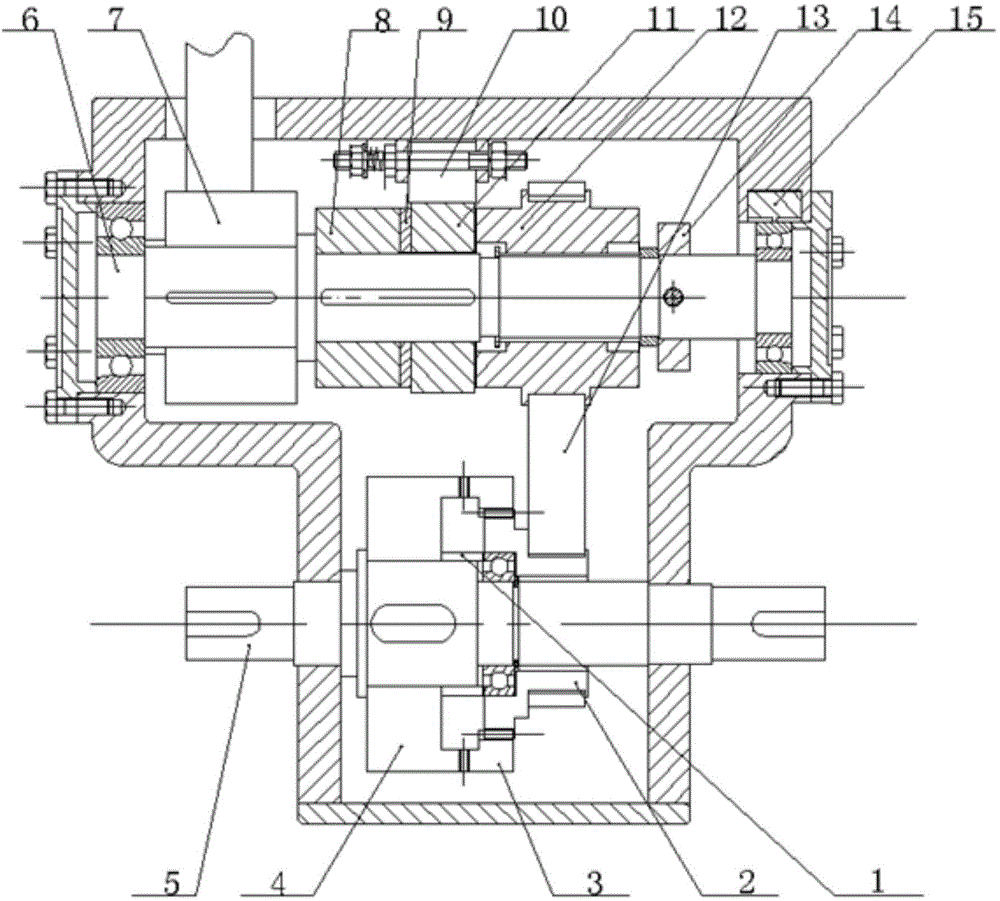

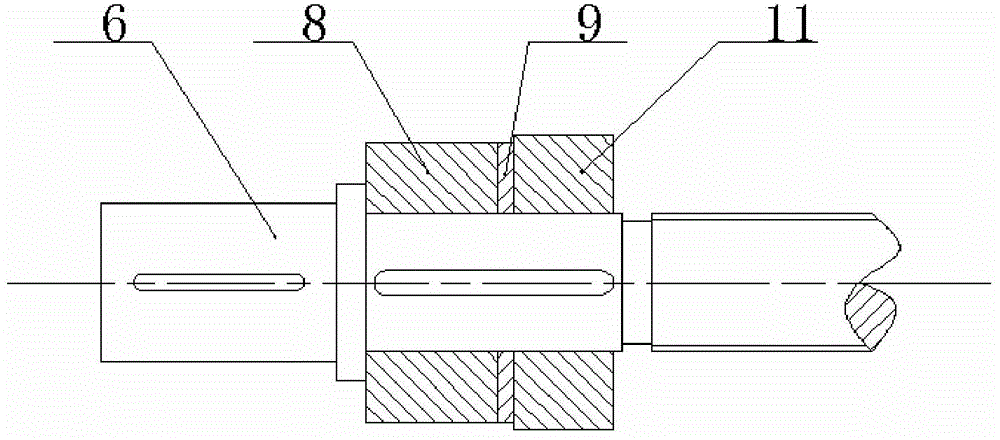

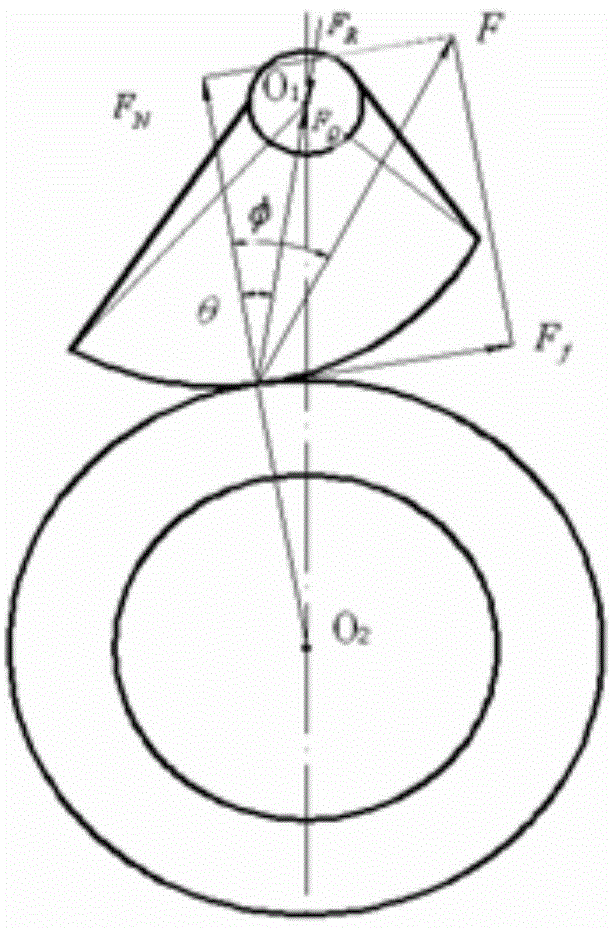

[0027] The multi-point electronically controlled binding device for vehicle goods provided by the present invention is mainly composed of a DC motor, an electromagnetic clutch, an armature, a braking device, a ratchet mechanism, and large and small pulleys connected by a synchronous toothed belt, wherein: the small pulley It is connected with the armature through a gear pair, and the armature can move axially. The armature cooperates with the electromagnetic clutch. The large pulley is connected with the threaded shaft through the threaded pair. The ratchet mechanism consists of a ratchet mounted on the threaded shaft and a ratchet mounted on the box. The claw is composed of claws; in the working state, the electromagnetic clutch is energized, and it is sucked together with the armature to drive the small pulley to rotate; by controlling the positive and negative rotation of the input shaft, the positive and negative rotation of the threaded shaft is realized, so as to realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com