Method for detecting fault of high-voltage circuit of blade electric vehicle

A pure electric vehicle, high-voltage loop technology, applied in circuits or fluid pipelines, vehicle components, transportation and packaging, etc., can solve the problems of long search time and long vehicle maintenance time, achieve rapid positioning and shorten maintenance. time, the effect of narrowing the search

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

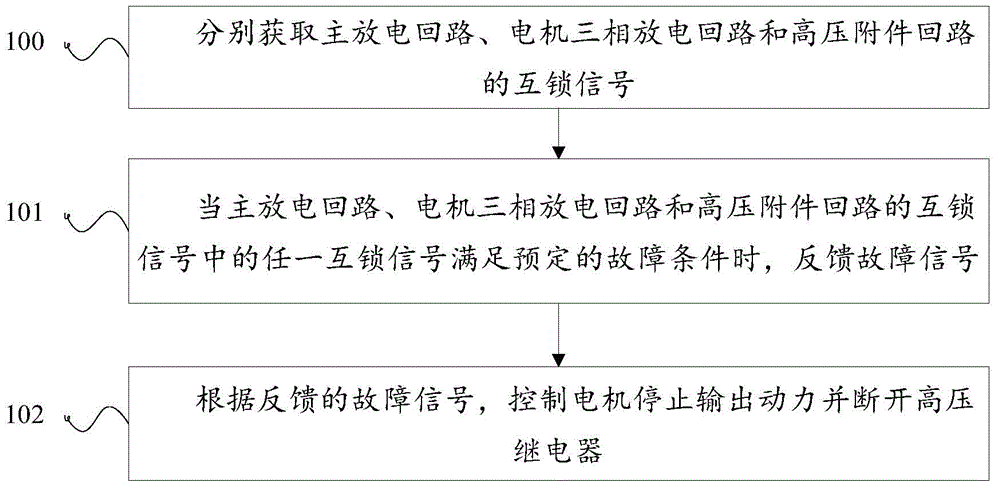

[0041] see figure 1 , the present embodiment provides a fault detection method for a high-voltage loop of a pure electric vehicle. The high-voltage loop includes: a main discharge loop, a motor three-phase discharge loop, and a high-voltage accessory loop. The method includes:

[0042] Step 100, obtaining the interlock signals of the main discharge circuit, the motor three-phase discharge circuit and the high-voltage accessory circuit respectively;

[0043] Step 101, when any one of the interlock signals of the main discharge circuit, the three-phase discharge circuit of the motor and the high-voltage accessory circuit satisfies a predetermined fault condition, feed back a fault signal;

[0044] Step 102, according to the feedback fault signal, control the motor to stop outputting power and disconnect the high voltage relay.

[0045] Through the above operations, the detected high-voltage loop is divided into three loops: the main discharge loop, the motor three-phase dischar...

Embodiment 2

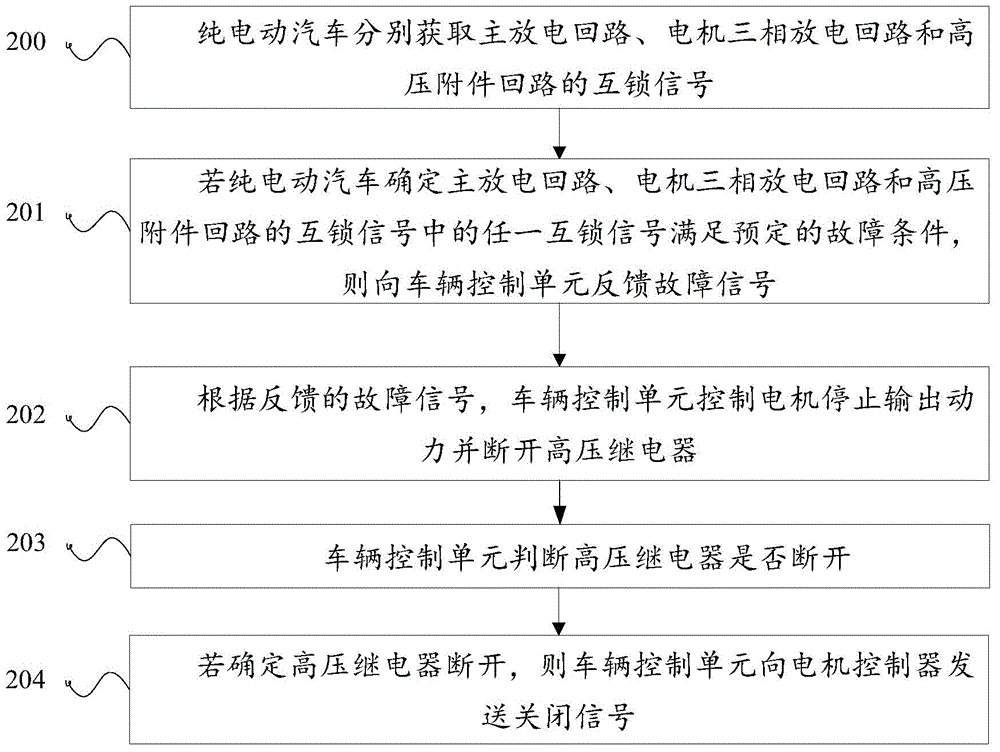

[0047] see figure 2 , the present embodiment provides a fault detection method for a high-voltage loop of a pure electric vehicle. The high-voltage loop includes: a main discharge loop, a motor three-phase discharge loop, and a high-voltage accessory loop. The process of the method includes:

[0048] Step 200, the pure electric vehicle obtains the interlocking signals of the main discharge circuit, the motor three-phase discharge circuit and the high-voltage accessory circuit respectively.

[0049] Specifically, the battery management system of the pure electric vehicle obtains the interlock signal of the main discharge circuit, the motor controller of the pure electric vehicle obtains the interlock signal of the three-phase discharge circuit of the motor, and the vehicle control unit of the pure electric vehicle obtains the interlock signal of the high-voltage accessory circuit. lock signal.

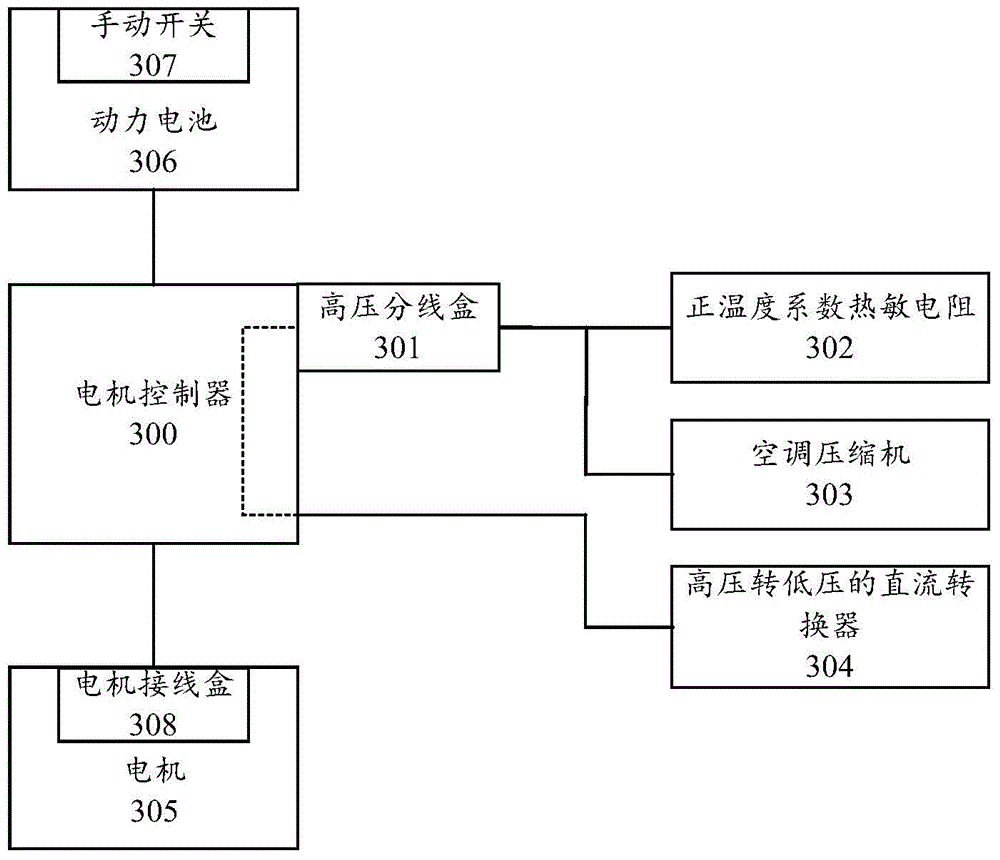

[0050] Among them, the schematic diagrams of the main discharge circuit, the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com