Revolving positioning mechanism

A technology of positioning mechanism and swivel seat, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems affecting the annealing effect of vials, achieve the effects of simple structure, improved quality and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

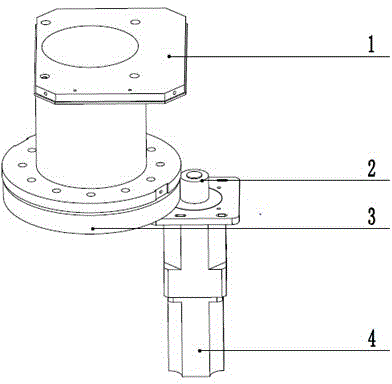

[0008] Depend on figure 1 It is known that a rotary positioning mechanism is composed of a rotary seat 1, a gear 2, a rotary bearing 3, and a servo motor 4. The slewing support 3 is directly connected to the slewing base 1 with screws, the gear 2 is directly fixed on the power output shaft of the servo motor 4, and the gear 2 and the slewing support 4 are connected and installed in pairs. After the servo motor 4 is energized and started, it drives the gear 2 connected to it to rotate. When the gear 2 rotates, it synchronously drives the slewing bearing 3 matched with it to rotate. When the slewing bearing 3 rotates, it rotates together with the slewing seat 1 fixedly connected with it, so that the slewing positioning mechanism can rotate like this. The rotation angle or number of turns and the direction of rotation of the rotary positioning mechanism can be obtained through the number of rotation pulses and rotation direction pulses sent by the host computer controller.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com