Parallel connection screw conveyer bin discharging conveying machine

A conveyor and screw conveyor technology, applied in the field of parallel auger out-of-warehouse conveyors, can solve problems affecting the normal process of the process, and achieve the effect of improving transmission efficiency and warehouse clearance speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

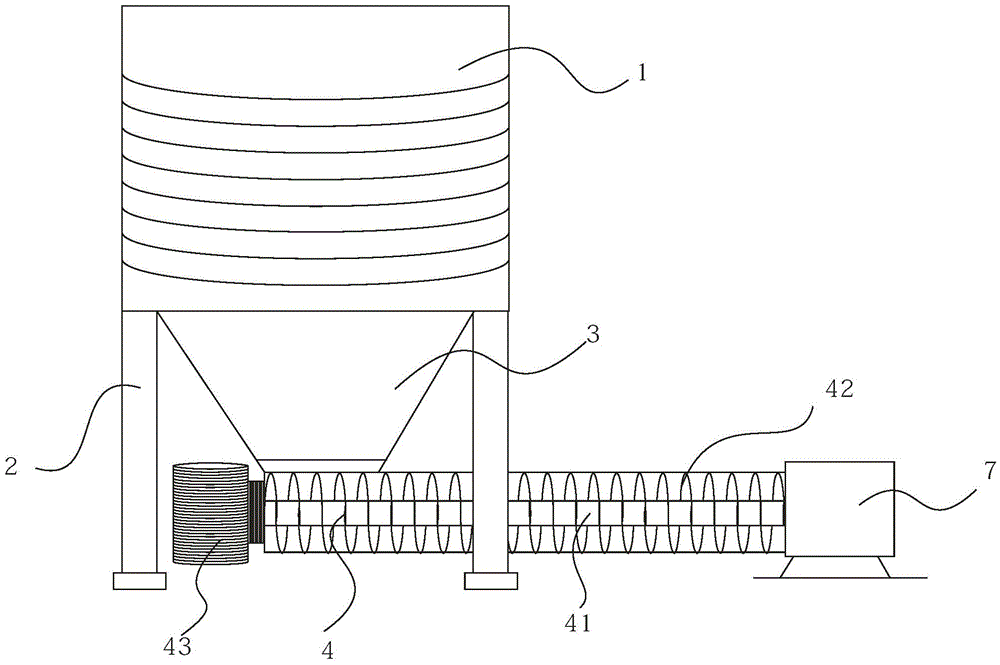

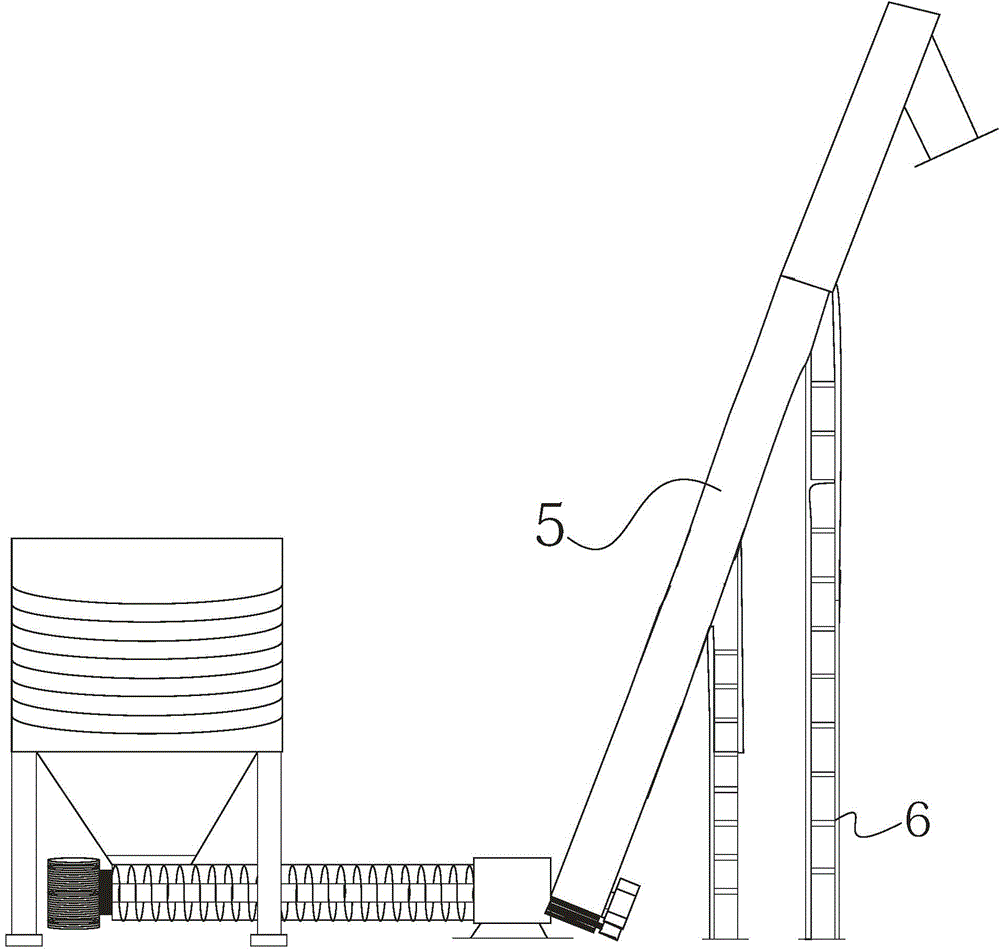

[0013] figure 1 Shown is a schematic diagram of the structure of the parallel auger discharge conveyor, the parallel auger discharge conveyor includes a storage bin 1, and a cone bucket 3 with a discharge port is arranged below the storage bin 1; the storage bin 1 A support frame 2 is arranged around the cone bucket 3; a parallel auger 4 is installed at the outlet of the cone bucket 3. The parallel auger 4 comprises at least two helical shafts 41 arranged side by side and helical blades 42 on the helical shaft. The parallel auger 4 is connected with a transmission device 43; the end of the helical shaft 41 is provided with a The bin 7; the material in the storage bin 1 directly contacts the spiral blade 42 of the parallel auger 4, and when it is out of the bin, the parallel auger 4 is directly started, and the spiral blade 42 destroys the arch of the material when it rotates, pushes the material out of the bin, and then passes through the parallel auger. The auger is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com