Die cutting machine

A die-cutting machine and servo motor technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problem that overlapping paper feeding cannot be realized, and achieve the effect of accurate positioning and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

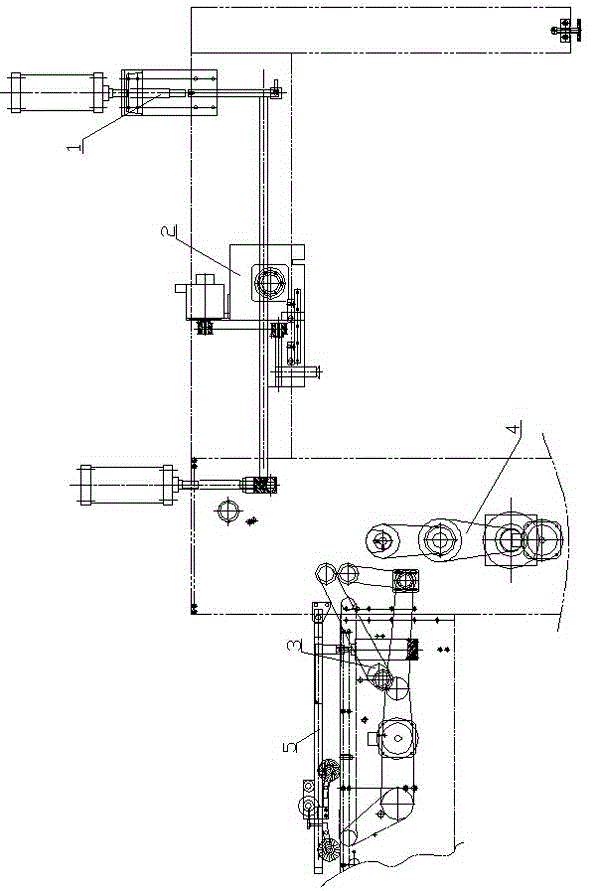

[0027] A die-cutting machine, see attached figure 1 to attach Figure 12 , in the figure: lifting mechanism 1, feeder transmission mechanism 2, paper feeding belt transmission mechanism 3, paper feeding cam transmission mechanism 4, paper feeding frame mechanism 5.

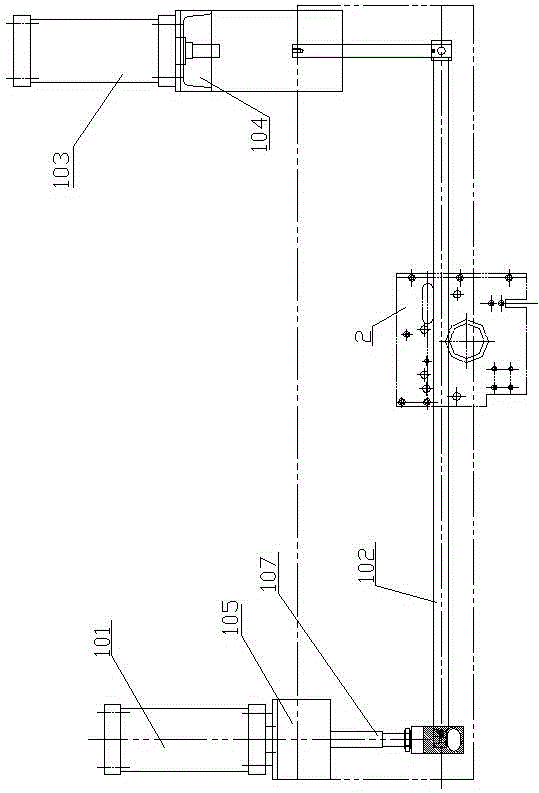

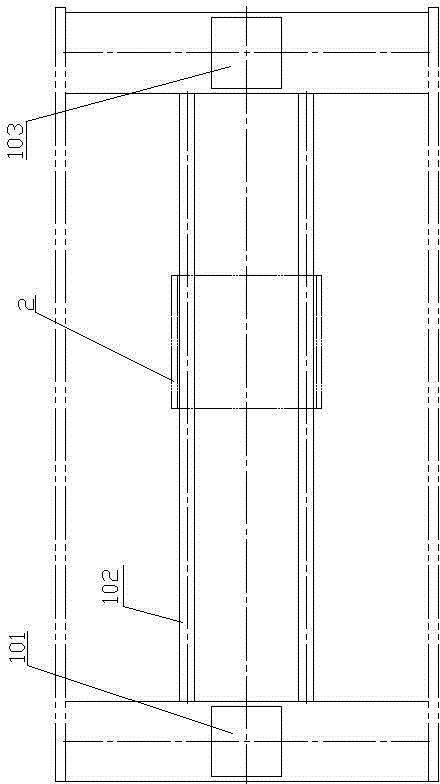

[0028] In the lifting mechanism 1: cylinder 101, front and rear moving guide rail 102, cylinder 103, cylinder 101, cylinder 103, support 104, support 105, connecting rod 106, connecting rod 107.

[0029] In Feida transmission mechanism 2: servo motor 201, driving synchronous pulley 202, synchronous belt 203, driven synchronous pulley 204, driving gear 205, driven gear 206, screw shaft 207, screw nut 208, mounting plate 209 , Paper delivery rod fixing block 210, paper delivery rod 211, main shaft servo motor 212, servo reducer 213, linear guide rail seat 214, linear guide rail 215.

[0030] In the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap