Fluid canning crane pipe automatic-alignment device

An automatic alignment and canning technology, which is applied to distribution devices, liquid distribution, transportation or transfer devices, special distribution devices, etc., can solve the problems of inaccurate alignment between vertical pipes and tank mouths, low work efficiency, and high work intensity , to achieve the effect of reducing the intensity of manual operation, high work efficiency, and avoiding manual misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

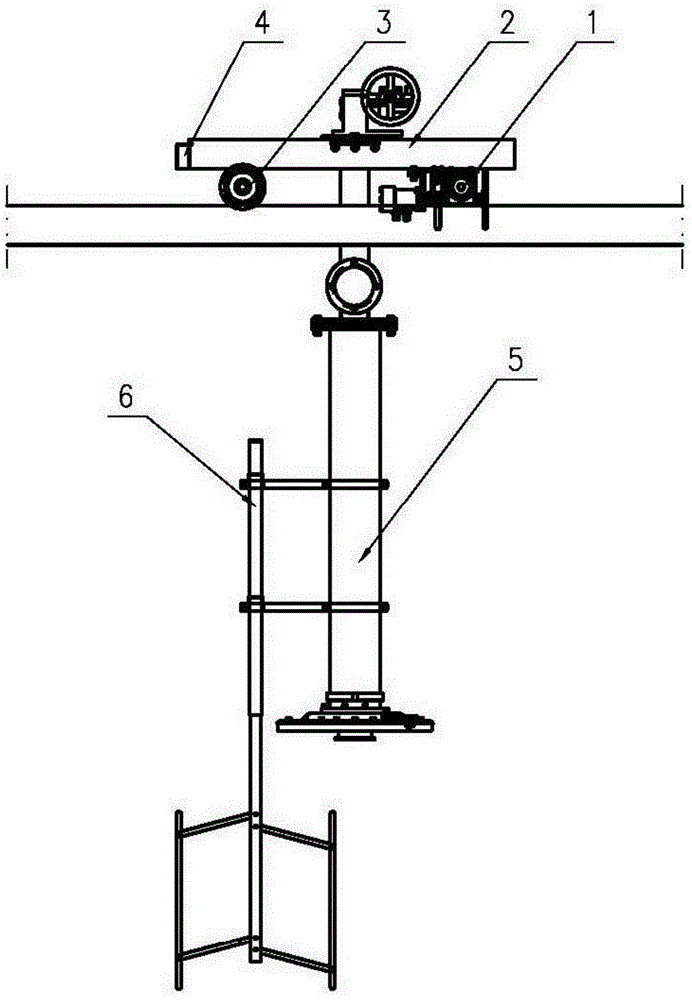

[0008] An automatic alignment device for a fluid canned crane tube, such as figure 1 As shown, it includes a truss, a truss vehicle 2 with traveling wheels and a controller. The power output device 1 installed on the truss vehicle 2 drives the traveling wheels to rotate, and the controller controls the work of the power output device 1, and even the traveling wheels drive the truss vehicle 2. Move along the two-dimensional coordinate plane on the truss, and the vertical pipe 5 used to hang directly above the tank opening opened on the top of the carried tank body by the power output device 1 in a hanging manner to dock the tank mouth is installed on the truss vehicle 2; On the truss truck 2, a rotary encoder 3 for measuring the speed of the road wheel and its direction of rotation and a non-contact scanning rangefinder 4 for scanning the outer surface of the tank body top are installed; when the non-contact scanning rangefinder 4 At least when the tank mouth is scanned, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com