Preparation method of high-purity 5-vinyl oxazolidine-2-thioketone

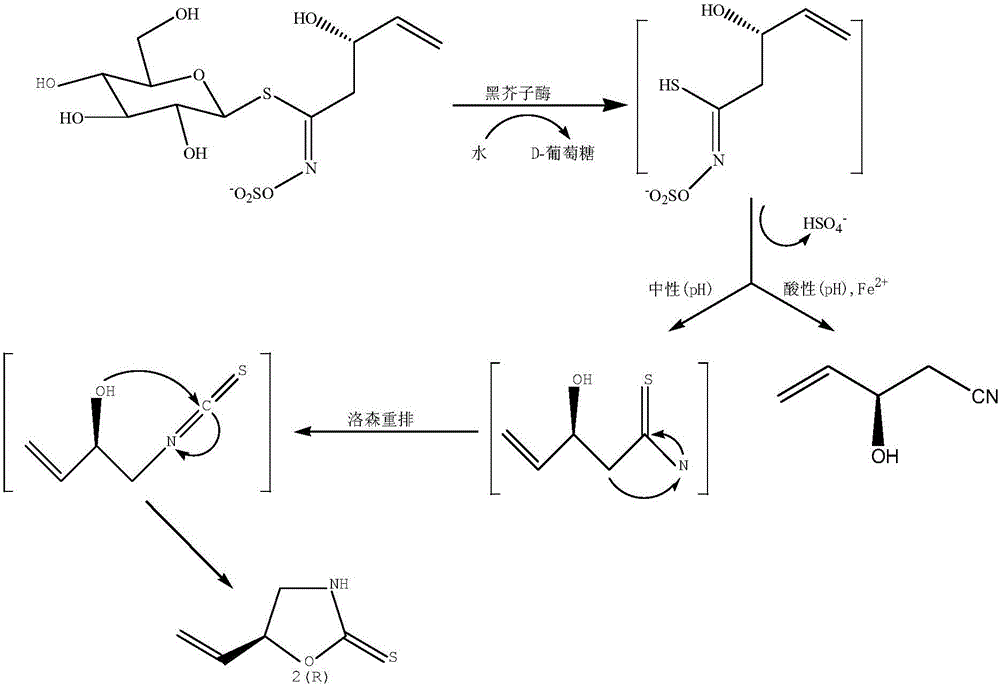

A high-purity technology of oxazolidine, which is applied in the field of organic chemical industry, can solve the problem of low purity of 5-vinyloxazolidine-2-thione, and achieve the effect of low cost, convenient operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

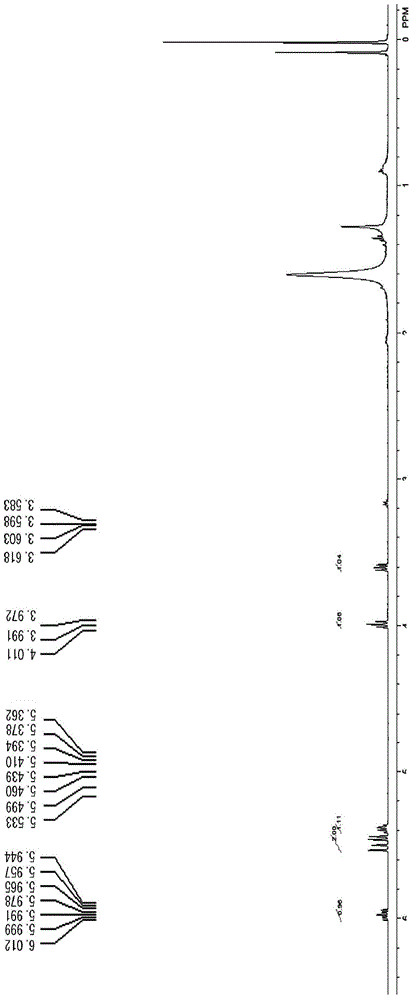

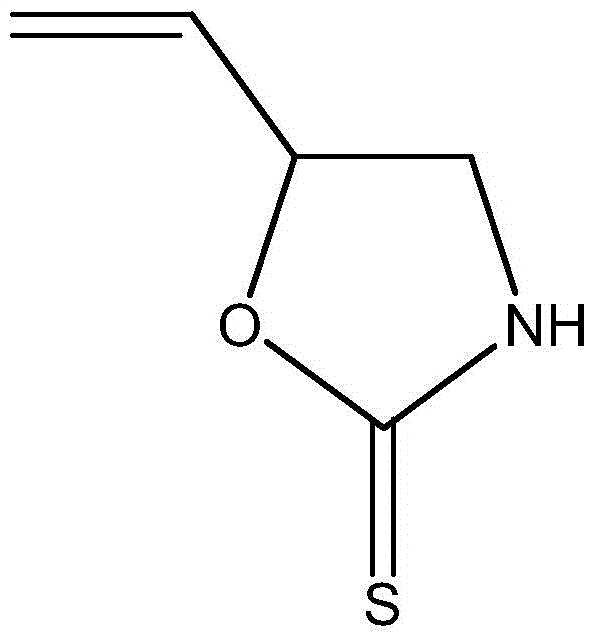

[0037] A kind of preparation method of high-purity 5-vinyl oxazolidine-2-thione:

[0038] Dissolve 1-amino-3-buten-2-ol (480 mg) in water (20 mL), add potassium hydroxide (0.38 g) and carbon disulfide (0.44 mL), stir well, and heat the oil bath to 60 ℃, and then a mixed aqueous solution (15 mL) containing potassium hydroxide (0.44 g) and lead nitrate (2.21 g) was added to the reaction system, and the temperature of the oil bath was kept constant, and stopped after heating for 75 min. The black precipitate was removed by centrifugation, the supernatant was taken and rotated in a water bath at 50 °C, and the remaining solid was dissolved with saturated sodium chloride solution (15 mL), extracted with 3 times the volume of ethyl acetate, and evaporated to dryness to obtain 5- The crude product of vinyloxazolidine-2-thione (498 mg) was 70% in yield and 80% in purity.

[0039] Then the crude product was dissolved in distilled water (166 mL) to prepare an aqueous solution (30 mg / mL...

Embodiment 2

[0046] A kind of preparation method of high-purity 5-vinyl oxazolidine-2-thione:

[0047] Dissolve 1-amino-3-buten-2-ol (830 mg) in water (35 mL), add potassium hydroxide (0.66 g) and carbon disulfide (0.76 mL), stir well, and heat the oil bath to 60 ℃, and then a mixed aqueous solution (26 mL) containing potassium hydroxide (0.76 g) and lead nitrate (3.82 g) was added to the reaction system, and the temperature of the oil bath was kept constant, and stopped after heating for 75 min. The black precipitate was removed by centrifugation, the supernatant was taken and rotated in a water bath at 50 °C, and the remaining solid was dissolved with saturated sodium chloride solution (26 mL), extracted with 3 times the volume of ethyl acetate, and evaporated to dryness to obtain 5- The crude product of vinyloxazolidine-2-thione (837 mg) has a yield of 68% and a purity of 80%.

[0048] Then the crude product was dissolved in distilled water (24 mL) to prepare an aqueous solution (35 mg...

Embodiment 3

[0051] A kind of preparation method of high-purity 5-vinyl oxazolidine-2-thione:

[0052] Dissolve 1-amino-3-buten-2-ol (1700 mg) in water (71 mL), add potassium hydroxide (1.35 g) and carbon disulfide (1.56 mL), stir well, and heat the oil bath to 60 ℃, and then a mixed aqueous solution (53 mL) containing potassium hydroxide (1.56 g) and lead nitrate (7.83 g) was added to the reaction system, and the temperature of the oil bath was kept constant, and stopped after heating for 75 min. The black precipitate was removed by centrifugation, the supernatant was taken and rotated in a water bath at 50 °C, and the remaining solid was dissolved with saturated sodium chloride solution (53 mL), extracted with 3 times the volume of ethyl acetate, and evaporated to dryness to obtain 5- The crude product of vinyloxazolidine-2-thione (1638 mg) has a yield of 65% and a purity of 80%.

[0053] Then the crude product was dissolved in distilled water (41 mL) to prepare an aqueous solution of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap