Novel production line of composite grease lubrication material

A technology of lubricating materials and compound grease, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of transportation and weighing of unfavorable compound grease lubricating materials, and achieve the effect of ensuring uniformity, reasonable design and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

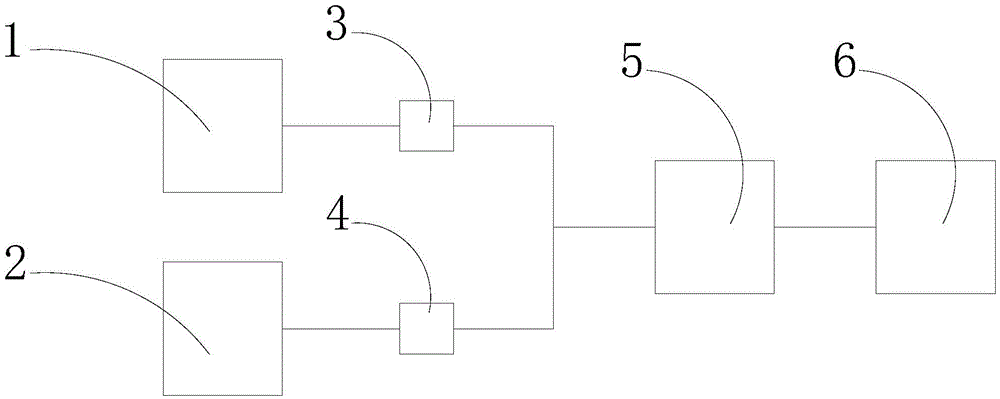

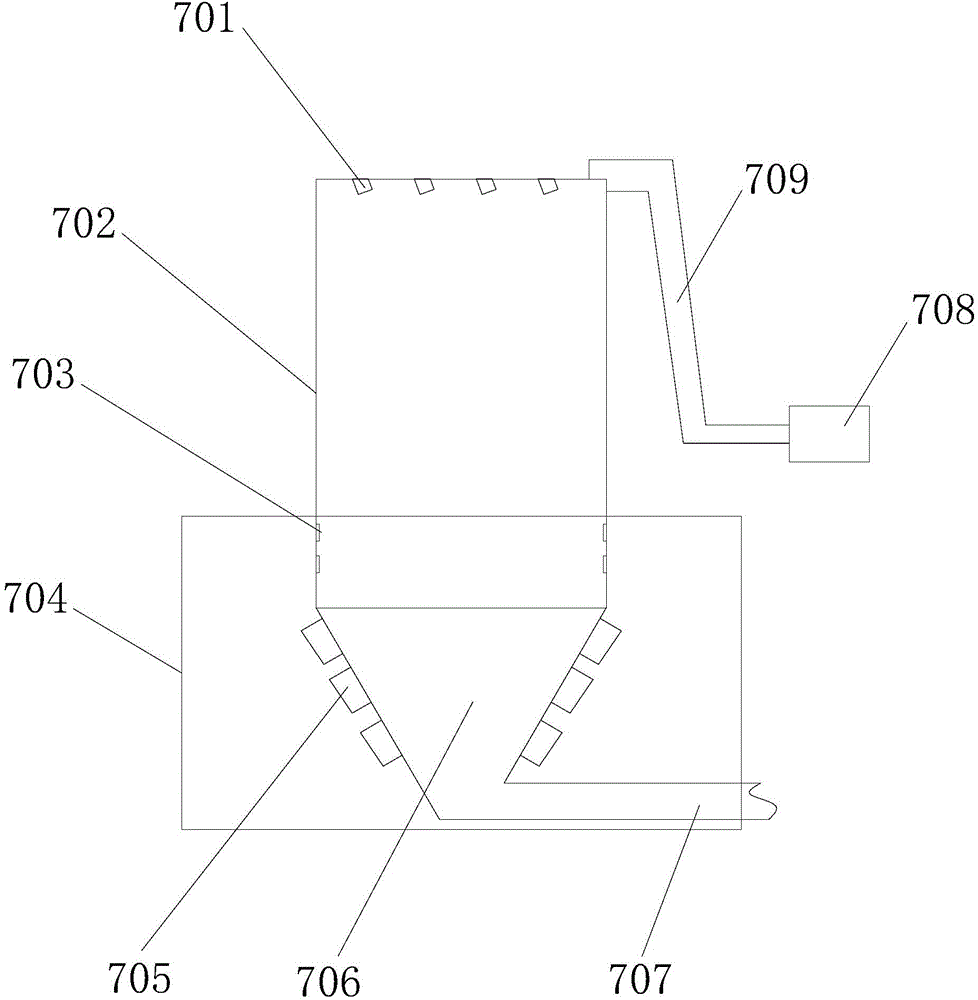

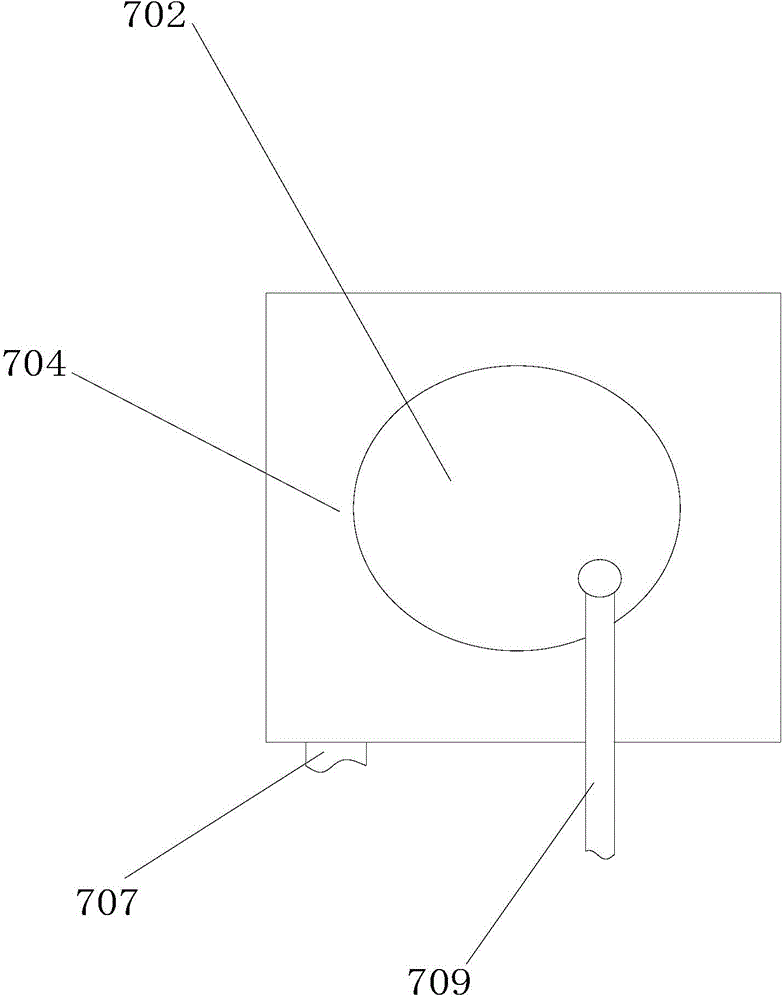

[0026] Such as figure 1 As shown, a new compound grease lubricating material production line includes a hydrogenated oil storage tank 1 and a first reactor 2, and the hydrogenated oil storage tank 1 and the first reactor 2 communicate with the second reactor 5 through pipelines respectively, so that The second reaction kettle 5 is connected to the bead spraying device 6 through a pipeline. The function of the first reaction kettle 2 is to fully stir and mix the paraffin and low molecular weight polyethylene, and the hydrogenated oil storage tank 1 stores liquid hydrogenated oil. The hydrogenated oil used in the prior art is solid, and needs to be reheated to 150° to melt after purchase. In this embodiment, an insulated tank is used, and the hydrogenated oil can be processed and transported in a liquid form by the manufacturer to the insulated tank of our factory. Use it directly afterwards. The advantage of this is that it can be directly filled into the insulation tank, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com