Rice bran oil degreasing method by adding crystal nucleuses

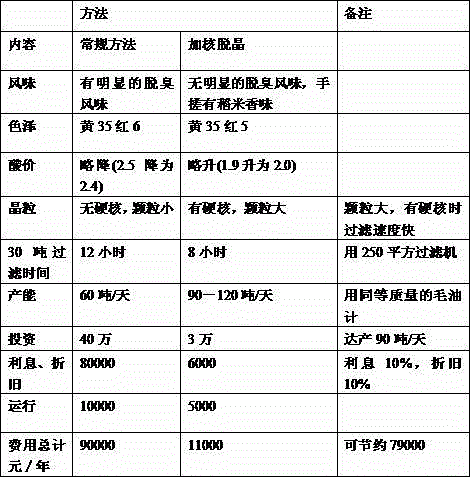

A technology of rice bran oil and crystal nucleus, which is applied in the degreasing field of rice bran oil plus crystal nucleus, can solve the problems of affecting oil yield, filtration process failure, and affecting the quality of finished oil, so as to achieve purer and more fragrant taste, improve appearance and color, reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Under the experimental conditions, take 500 grams of dewaxed oil (yellow 35 red 6), add 2.5 grams (0.5% of the oil) of activated carbon at 30 ° C and stir evenly, and slowly cool down to 4 ° C within 24 hours (by 1 hour in the refrigerator) ℃), and kept at 4 ℃ for 10 hours to grow crystals, and then took out the sample and filtered it with filter paper in a refrigerator at 4 ℃, and took the filtered clear oil for 0 ℃ test, and it could not be frozen for 8 hours, and the color (yellow 35, red 5), the gas taste is purer than crude oil, without the earthy smell of deodorized oil, and the blue value does not increase in the 280°C heating test.

Embodiment 2

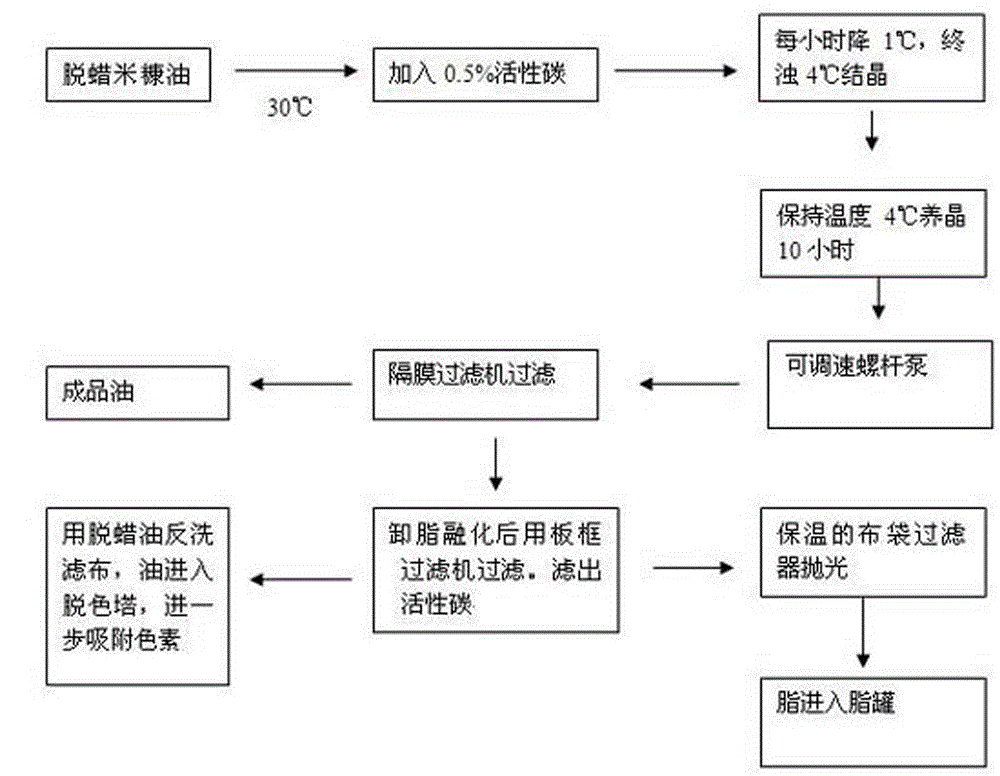

[0015] Concrete production process steps of the present invention are as follows:

[0016] ① Wait for the dewaxed oil to warm up. Use the oil that is first dewaxed and then deesterified, when the temperature in the crystallization tank drops to 35°C.

[0017] ② Add 0.3% of the oil to the premixing tank (activated carbon is purchased from wood activated carbon from a factory in Hunan, weight loss on drying ≤ 10%; chloride ≤ 0.2; heavy metal ≤ 0.01%; acidity and alkalinity (pH value) 2.0-5.0 ; particle size 180-200 mesh; caramel decolorization greater than or equal to 100%; iron salt ≤ 0.1%; in line with GB / T13803.3-1999 standard.), then add half a ton of oil, and stir evenly with a circulating pump + agitator, Pump into the crystallization tank and stir evenly.

[0018] ③ Continue to cool down, keep the cooling rate at 1°C / hour, and the final temperature is 3°C.

[0019] ④ Keep the oil temperature at 3°C and grow crystals for 24 hours.

[0020] ⑤ Filter. Filtrate with tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com