Spring compression aging cladding layer protection jig and using method thereof

A technology for protecting fixtures and aging, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of affecting work efficiency, large amount of scrap, damage to coating, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation, structure, features and functions of the spring compression aging coating protection fixture according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

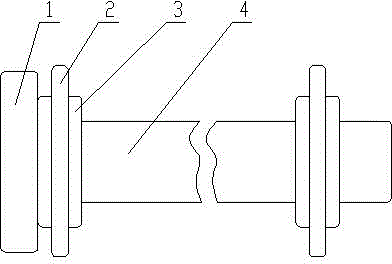

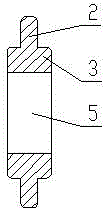

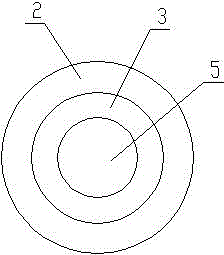

[0024] see Figure 1 to Figure 5 , the spring compression aging coating protection jig of the present invention comprises a jig body 3 and an aging mandrel 4, wherein: several jig bodies 3 are movably mounted on the aging mandrel 4, and a protruding positioning shoulder 2 is provided in the middle of the jig body 3, The fixture body 3 is axially provided with a through hole 5 , and one side of the aging mandrel 4 is provided with a stop 1 , and one of the fixture bodies 3 is installed at the stop 1 . There are two or more clamp bodies 3 . The clamp body 3 is symmetrical with respect to the median plane of the positioning shoulder 2 . The method for using the spring compression aging coating protection fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com