Copper alloy plate and electronic components for large current and electronic components for heat dissipation provided with the same

A copper alloy plate, using electronic technology, applied in the direction of electrical components, metal/alloy conductors, circuits, etc., to achieve the effects of high conductivity, high strength, and excellent drawing processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

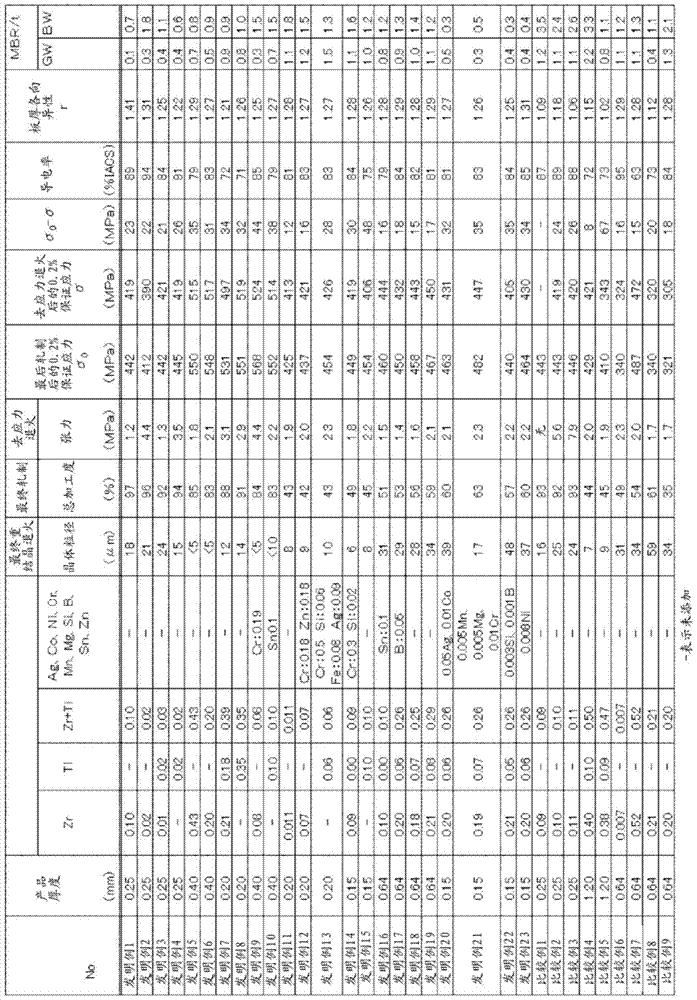

[0048] Examples of the present invention are shown below together with comparative examples. However, these examples are provided for better understanding of the present invention and its advantages, and are not intended to limit the invention.

[0049] After adding alloying elements to the molten copper, it is cast into an ingot with a thickness of 200 mm. The ingot was heated at 950° C. for 3 hours, and hot rolled to form a 15 mm thick plate. After grinding and removing scale on the surface of the hot-rolled sheet with a grinder, annealing and cold-rolling are repeated, and the final cold-rolling is finished to a given product thickness. Finally, a continuous annealing furnace is used for stress relief annealing.

[0050] The annealing (final recrystallization annealing) before final cold rolling used a batch furnace, the heating time was set to 5 hours, and the temperature in the furnace was adjusted within the range of 300 to 700° C. to change the crystal grain size and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

| elastic limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com