Method for transferring CVD graphene on metal copper surface to target substrate surface

A target substrate, graphene technology, applied in the field of materials, can solve the problem of waste of resources, copper cannot be directly reused, etc., to achieve the effect of reducing preparation cost, green and efficient transfer, and promoting large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

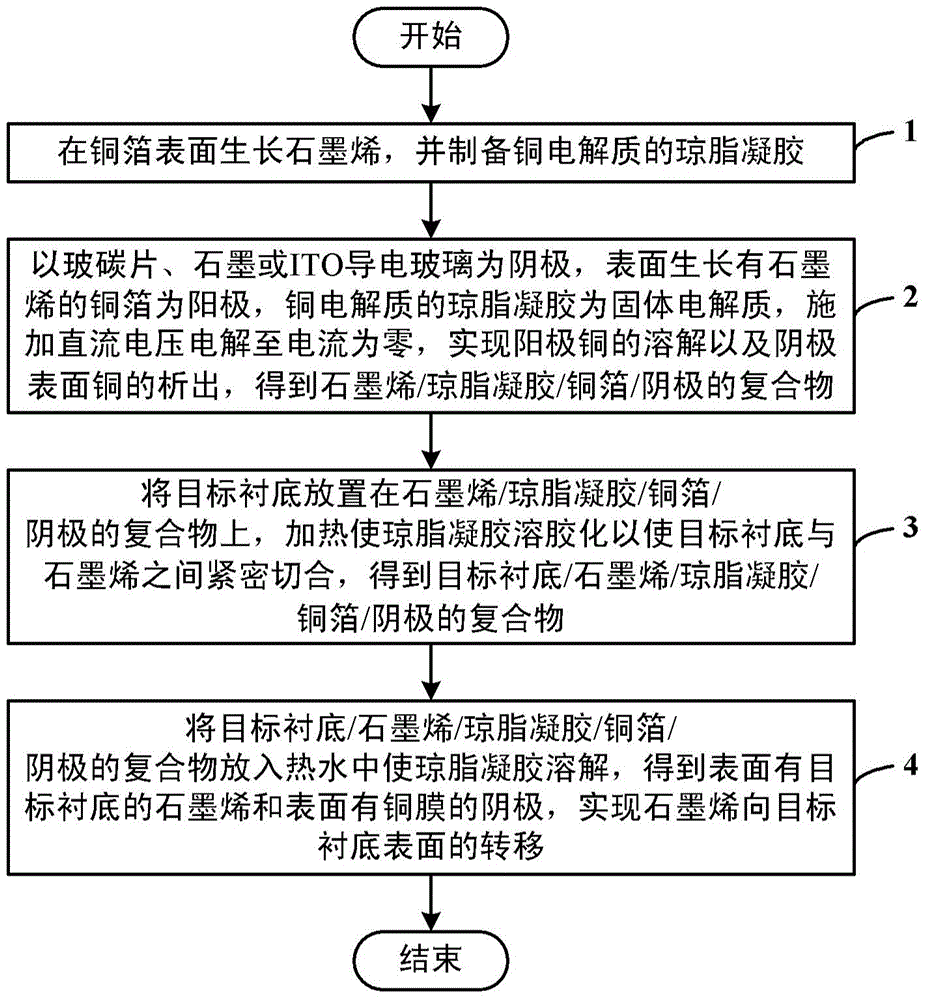

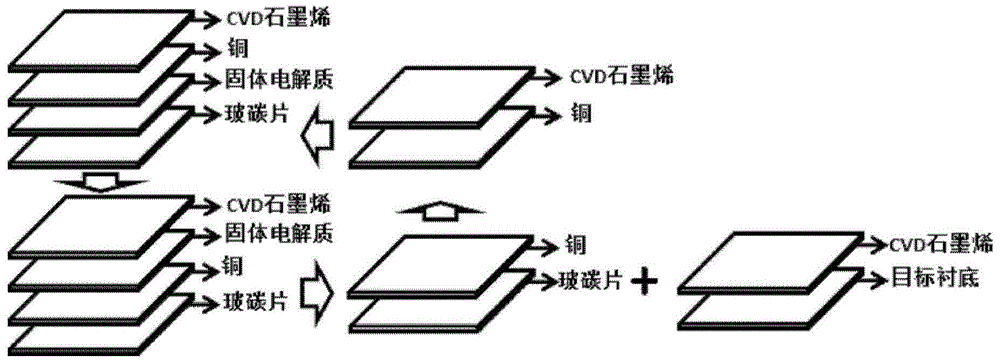

[0041] Embodiment 1: The target substrate is made of PET film, the copper electrolyte is made of copper sulfate, and the cathode is made of glassy carbon sheet, that is, the graphene deposited on the surface of metal copper by chemical vapor phase is transferred to the surface of the PET film in a green and efficient manner. The specific steps are as follows figure 2 as shown, figure 2 The process flow chart of graphene transfer according to embodiment 1 of the present invention is shown, including:

[0042] Weigh 10g of copper sulfate and 4g of agar powder, add 100ml of deionized water, heat and stir to make a sol solution, and naturally cool it to form an agar gel of copper sulfate; copper foil is put into a CVD furnace and heated under 10sccm hydrogen and 2sccm methane In a mixed atmosphere, use chemical vapor deposition to grow graphene on the copper surface at a high temperature of 1000°C; use a glassy carbon sheet as the cathode, and copper foil with graphene grown on ...

Embodiment 2

[0043] Embodiment 2: The target substrate is a PET film, the copper electrolyte is copper nitrate, and the cathode is a glassy carbon sheet, that is, the graphene chemically vapor deposited on the surface of the metal copper is transferred to the surface of the PET film in a green and efficient manner. The specific steps are as follows:

[0044] Take by weighing 10g copper nitrate and 4g agar powder, add 100ml deionized water, heat and stir to make sol solution, it is naturally cooled to form the agar gel of copper nitrate; Copper foil is put into CVD furnace, under 10sccm hydrogen and 2sccm methane In a mixed atmosphere, use chemical vapor deposition to grow graphene on the copper surface at a high temperature of 1000°C; use a glassy carbon sheet as the cathode, and copper foil with graphene grown on the surface as the anode, and the copper nitrate agar gel prepared above is the copper electrolyte. , apply a DC voltage of 0.7V to electrolyze until the current is zero, realize ...

Embodiment 3

[0045] Embodiment 3: The target substrate adopts PET film, the copper electrolyte adopts copper acetate, and the cathode adopts a glassy carbon sheet, that is, the graphene deposited by chemical vapor phase deposition on the surface of metal copper is transferred to the surface of the PET film in a green and efficient manner, and the specific steps are as follows:

[0046] Weigh 10g of copper acetate and 4g of agar powder, add 100ml of deionized water, heat and stir to make a sol solution, and naturally cool it to form an agar gel of copper acetate; copper foil is put into a CVD furnace and heated in 10sccm hydrogen and 2sccm methane In a mixed atmosphere, use chemical vapor deposition to grow graphene on the copper surface at a high temperature of 1000°C; use a glassy carbon sheet as the cathode, and copper foil with graphene grown on the surface as the anode, and the copper acetate agar gel prepared above is the copper electrolyte. , apply a DC voltage of 0.7V to electrolyze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com