Anti-oxidation experimental system for preparing nitrogen at room temperature during laser cladding

A technology of laser cladding and experimental system, applied in metal material coating process, coating, etc., can solve the problems of cladding layer quality degradation, sputtering, oxidation, etc., and achieve the effect of simple use and scientific and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The experimental system for nitrogen production and anti-oxidation at room temperature during laser cladding provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

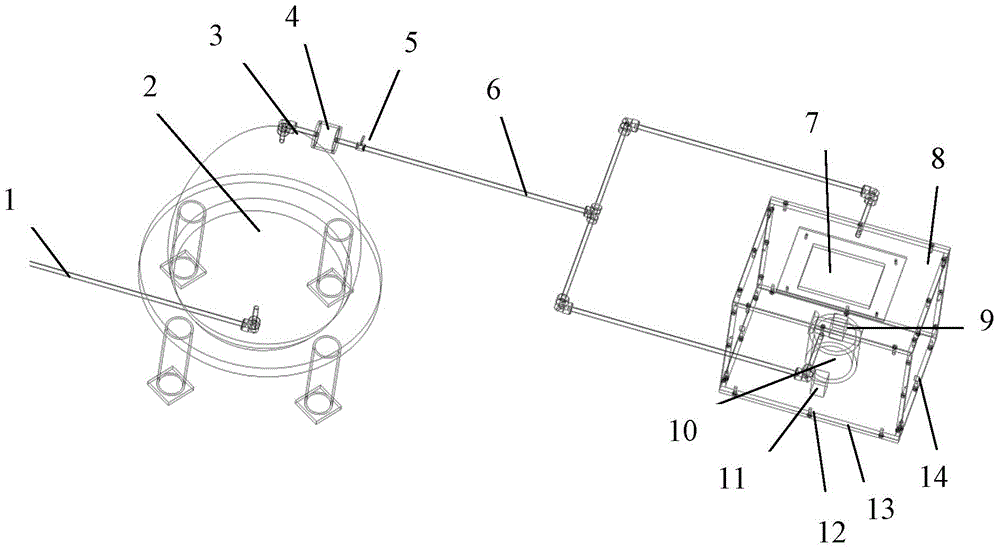

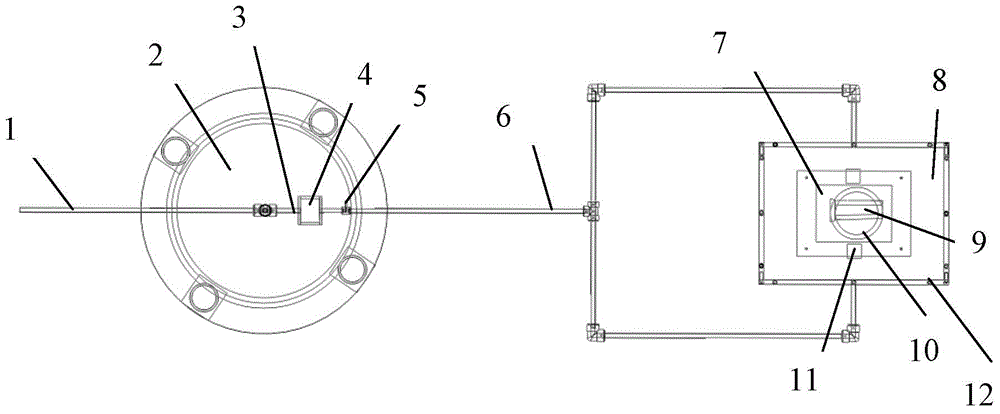

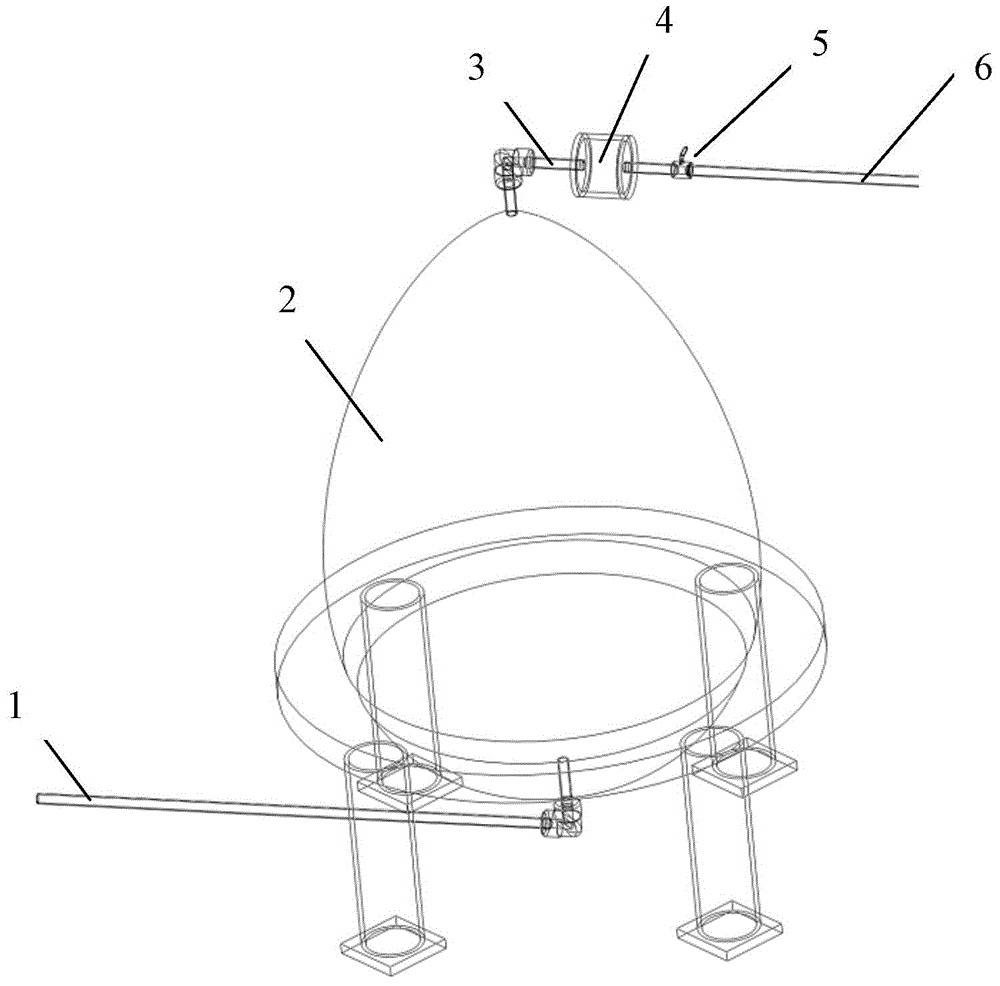

[0015] Such as figure 1 — Figure 4 As shown, the experimental system for producing nitrogen at normal temperature and preventing oxidation during laser cladding provided by the present invention is composed of two parts: a nitrogen producing machine at normal temperature and an anti-oxidation test box, wherein the nitrogen producing machine at normal temperature includes an inlet pipe 1, a nitrogen and oxygen separation tank 2, an outlet Trachea 3, glass box 4 and gas valve switch 5; Anti-oxidation test box includes gas delivery pipe 6, quartz plate 7, box body, hollow metal base 10 and two small bases 11; Described nitrogen and oxygen separation tank 2 is equipped with Carbon molecular sieve of oxygen molecules; one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com