Method for realizing cooking of broken bamboo chips

A realization method and cooking technology, which is applied in the direction of digesters, textiles, papermaking, papermaking, etc., can solve the problems of low cooking efficiency, waste of human resources, troublesome feeding and discharging, etc., and achieve good cooking effect and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

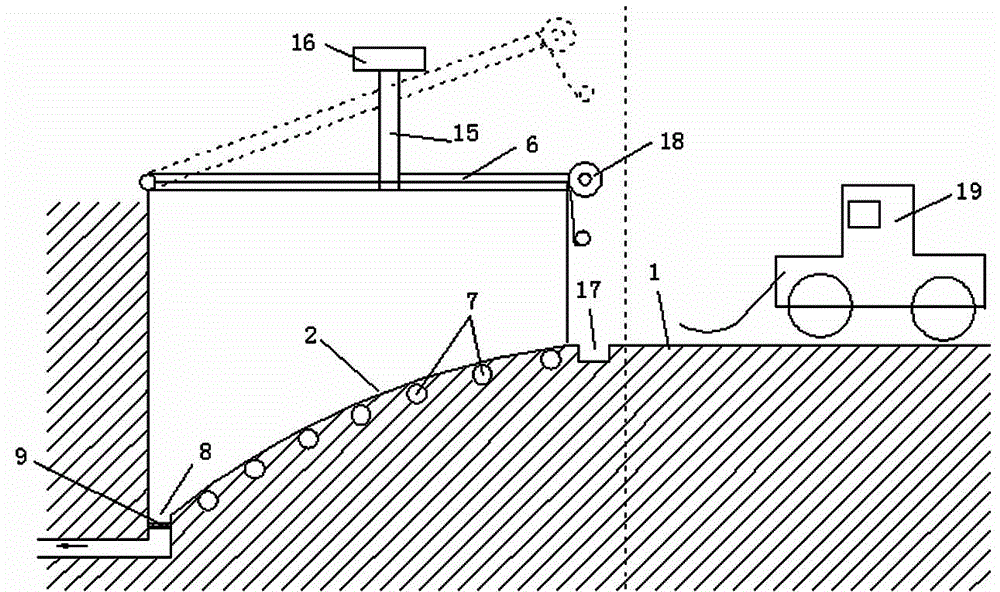

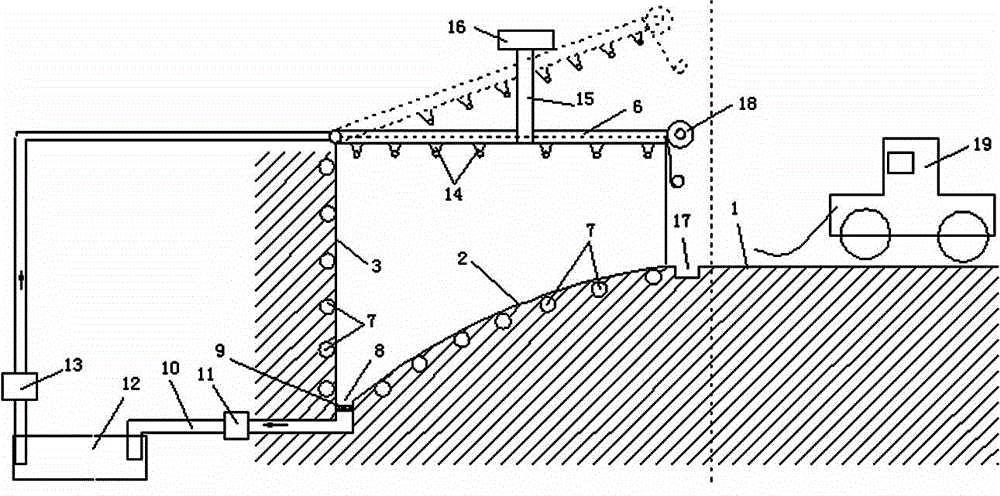

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

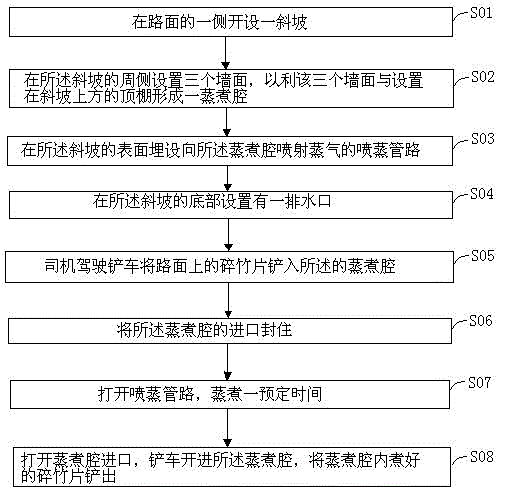

[0033] Such as figure 1 and figure 2 As shown, the present embodiment provides a method for steaming broken bamboo, which is characterized in that it comprises the following steps:

[0034] Step S01: set up a slope 2 on one side of the road surface 1;

[0035] Step S02: setting three walls around the slope 2, so that the three walls and the ceiling above the slope form a cooking cavity;

[0036] Step S03: Embedding a steam injection pipeline 7 on the surface of the slope to inject steam into the cooking chamber;

[0037] Step S04: setting a drain 8 at the bottom of the slope;

[0038] Step S05: the driver drives the forklift 19 to shovel the broken bamboo chips on the road into the cooking chamber;

[0039] Step S06: sealing the entrance of the cooking cavity;

[0040] Step S07: Open the steaming pipeline, and cook for a predetermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com