Soil Shoulder Blind Ditch System with Concentrated Drainage at the Side of Pavement

A technology for centralized drainage and soil shoulders, applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as unfavorable road cleaning, poor frost resistance, and incongruity, and achieve excellent driving safety and landscape effects, and stable guarantee functions Sexuality and long-acting, simple and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

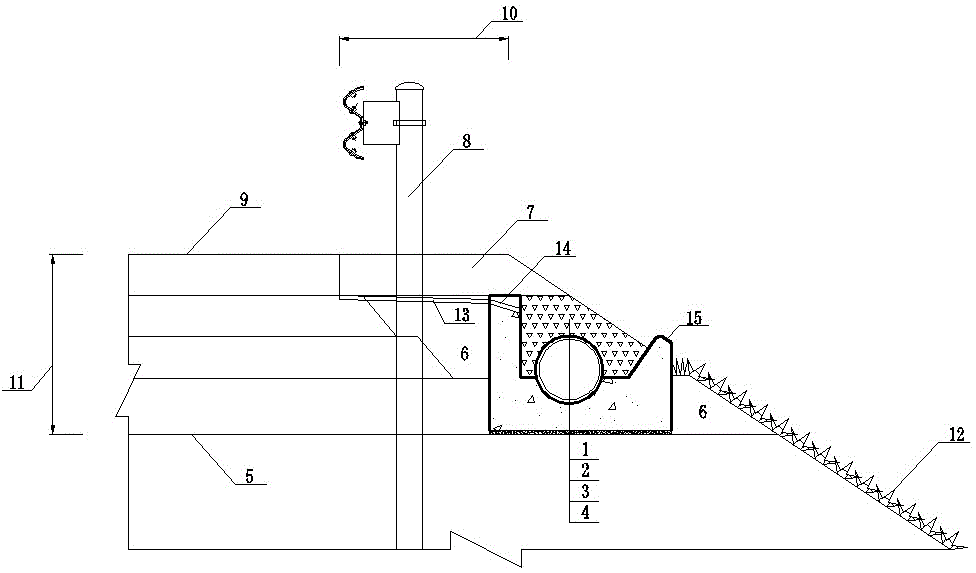

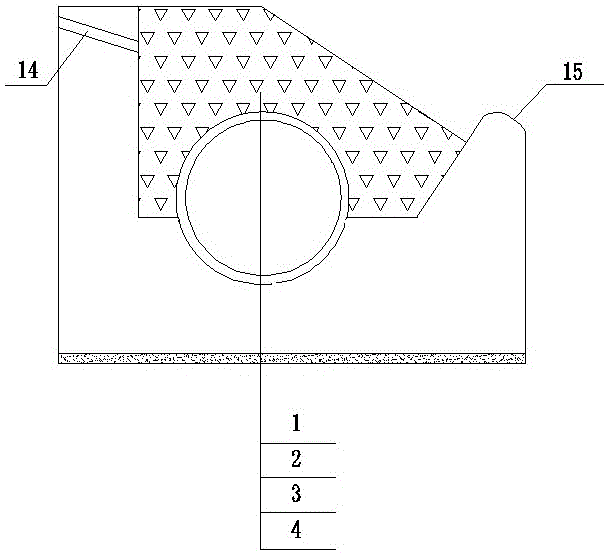

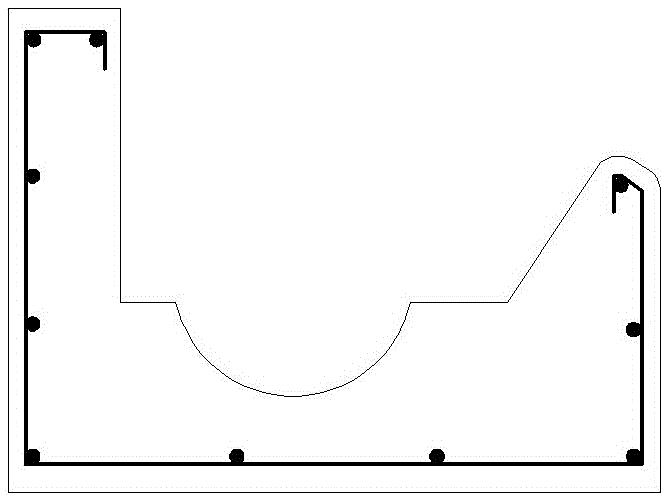

[0032] The present invention will be described in detail below in combination with specific embodiments.

[0033] The present invention relates to an soil road shoulder blind ditch system for concentrated drainage at the edge of the road surface. A cement concrete base 3 is arranged on the top surface 5 of the road bed at the edge of the road surface, outside the roadside guardrail 8, and along the longitudinal direction of the road, using C25 cement The concrete is prefabricated and reinforced, and the length of a single section is 50cm in consideration of the convenience of transportation. A layer of cement mortar 4 is applied to the bottom surface of the cement concrete base 3, and M10 cement mortar is used to fix the base and adjust the vertical slope. The cement concrete base 3 is a groove-shaped base with a U-shaped cross section, and a longitudinal groove is reserved at the bottom of the base groove, and a semi-permeable sand-free pipe 2 is placed in the groove. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com