Thermal regeneration asphalt stone material addition system

A technology of thermal regeneration and asphalt, applied in the direction of roads, road repair, roads, etc., can solve the problems of poor road paving effect and lack of asphalt viscosity of asphalt stone, and achieve the effect of improving properties and good paving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

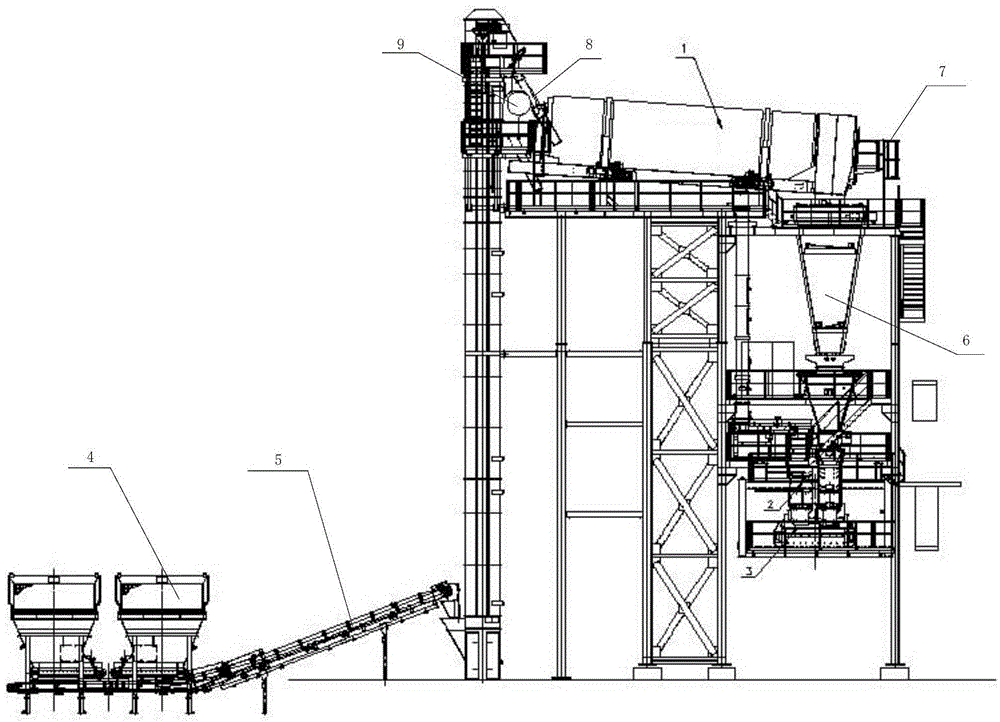

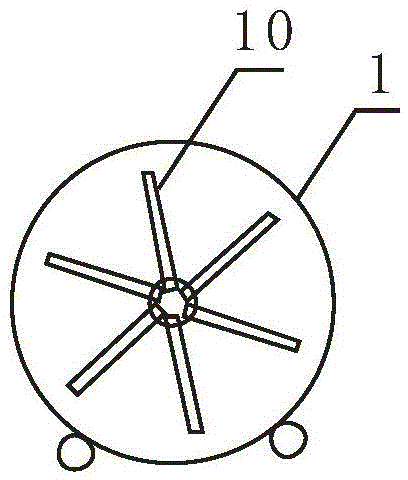

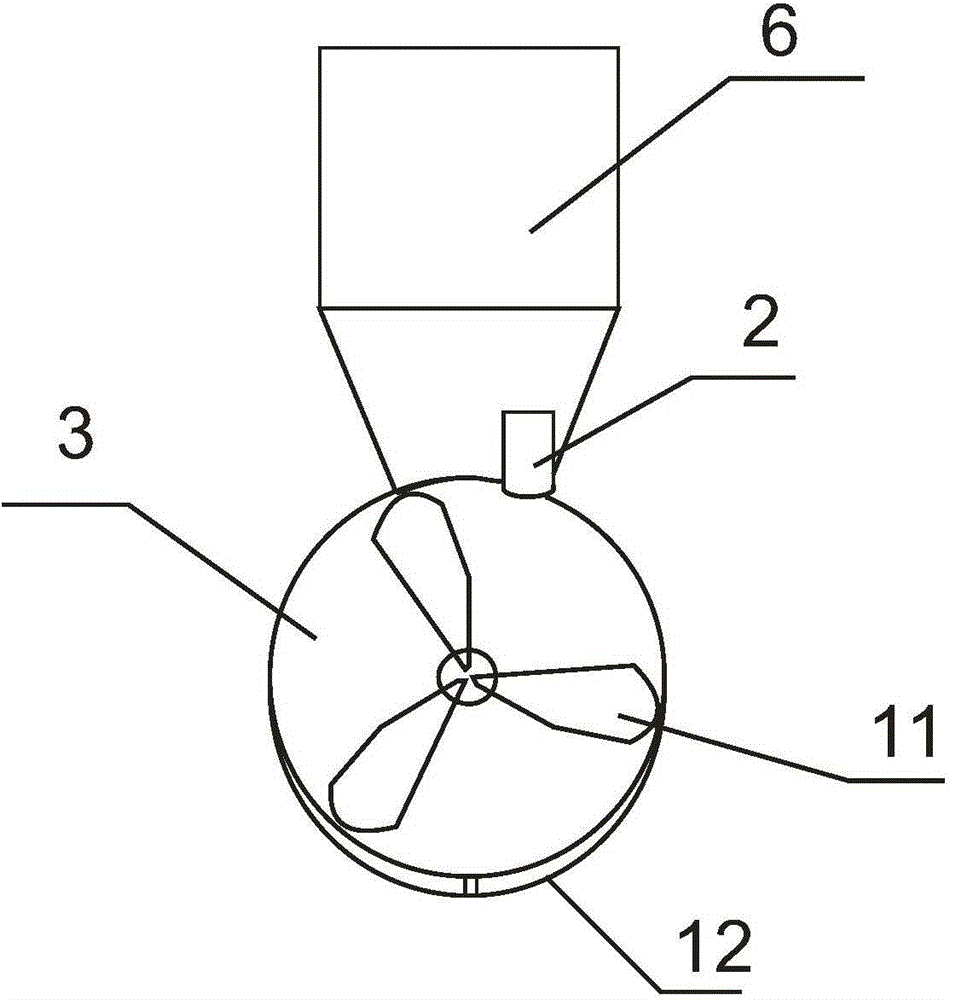

[0014] As shown in the figure, the present invention includes a silo 4, an equipment frame, a hoist 5 connected to the silo located on one side of the equipment frame, and a heating pipe bucket arranged on the top of the equipment frame and connected to the outlet 8 of the hoist and the outlet is inclined. 1. Connect the lower silo 6 at the outlet of the heating tube barrel and the mixing tank 3 located at the outlet of the lower hopper. The side of the low end outlet of the heating tube barrel is provided with a fuel injection port 7, and the high end inlet of the heating tube barrel is provided with An induced draft fan 9, a rotary turning gear 10 is provided inside the heating pipe barrel, a liquid asphalt nozzle 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com