Building method for scaffold used for drilling platform pile leg splicing

A technology for drilling platform pile legs and scaffolding, which is applied in the field of scaffolding, can solve the problems of labor and material resources, welding, grinding, inconvenient precision inspection, and difficulty in connecting piles, etc., and achieves the effects of flexible erection, low cost and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

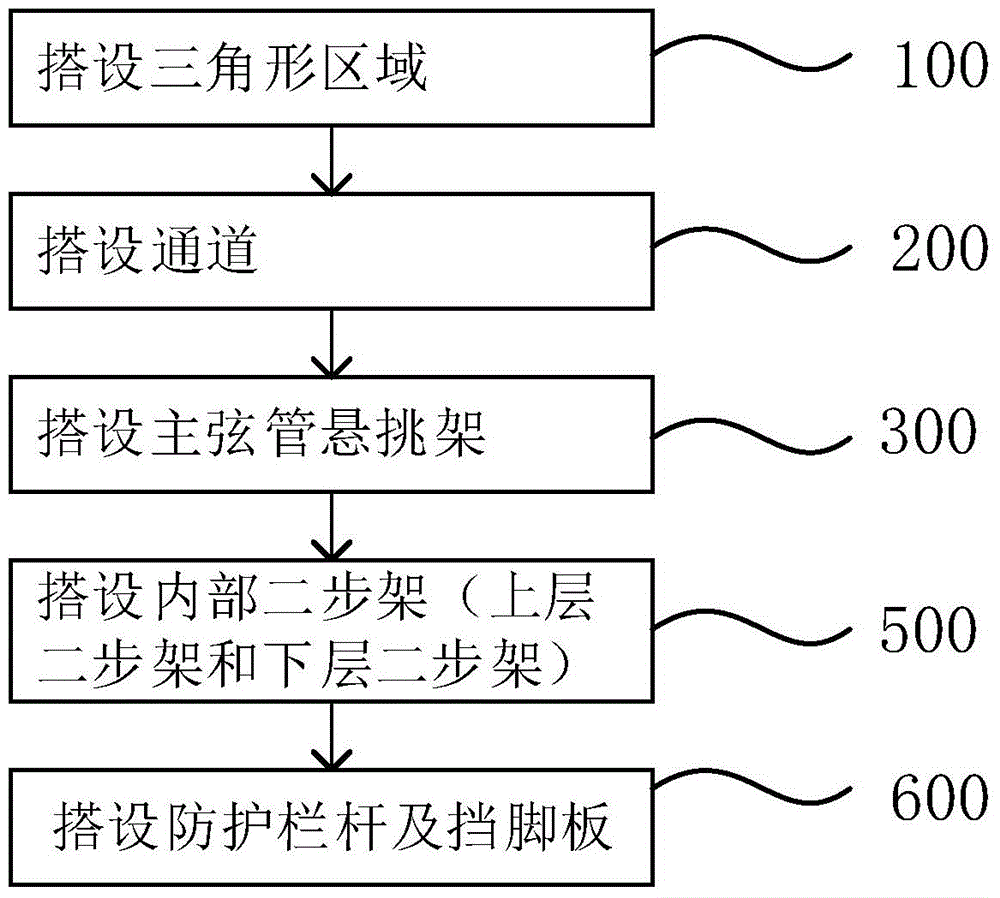

[0065] The order of setting up is to set up in four areas when setting up, step 100, set up a triangular area, then step 200, set up a channel, then step 300, set up a main chord suspension frame, and then step 500, set up an internal two-step frame (upper layer two Step frame and lower floor two-step frame), last step 600, set up protective railing and foot guard.

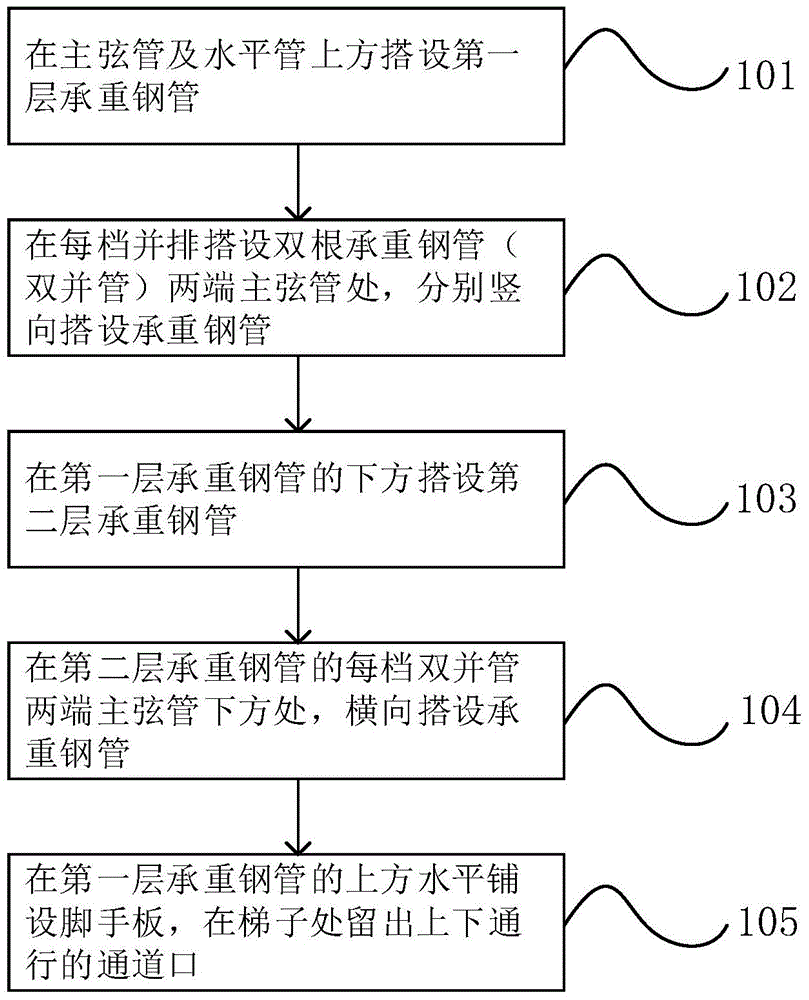

[0066] Step 100, setting up the triangular area also includes the following steps:

[0067] Step 101. First, erect the first layer of load-bearing steel pipes above the main chord pipe and the horizontal pipes, erect the first 6m load-bearing steel pipes starting from the horizontal pipes, and then erect three 6m steel pipes at intervals of 400mm from left to right along the direction of the horizontal pipes. Load-bearing steel pipes, 2 4.5m load-bearing steel pipes, 2 3.6m load-bearing steel pipes, 1 3m load-bearing steel pipes, 1 2.5m load-bearing steel pipes, 2 1.2m load-bearing steel pipes, 2 2.5m load-bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com