Bottom plate transportation type bridge passing ship lock

A technology of bottom plate and ship lock, which is applied in the direction of ship lock, ship lifting device, climate change adaptation, etc. It can solve the problems of downstream water surface fluctuation, long time, and affecting the safe passage of ships, so as to improve efficiency, reduce power consumption, and improve overall utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

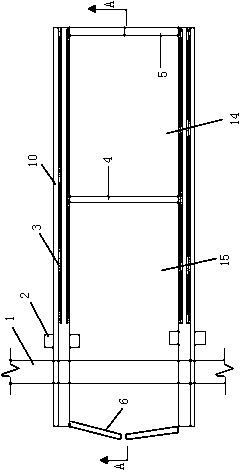

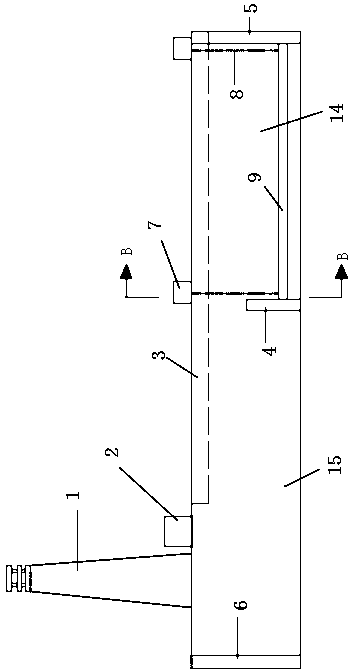

[0038] It can be seen from the accompanying drawings that the floor transport type bridge ship lock is arranged in the river below the bridge 1, and the bridge ship lock includes two lock chamber side walls 10 parallel to each other, an upstream gate 5, a midstream gate 4, a downstream gate 6, an opening Shutdown 7, transport base plate 9, and pumping device 2;

[0039]Wherein, the upstream gate 5, the downstream gate 6 and two lock chamber side walls 10 parallel to each other form a ship lock chamber, the midstream gate 4 is located in the ship lock chamber, and both sides of the midstream gate 4 are respectively sealed and fixed to the corresponding lock chamber sides, The midstream gate 4 divides the lock chamber into an upstream lock chamber 14 and a downstream lock chamber 15;

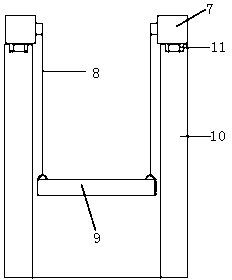

[0040] The tops of the two lock chamber side walls 10 are respectively provided with transport tracks 3, and each transport track 3 is provided with two hoists 7, and the bottom of each hoist 7 is...

Embodiment 2

[0049] The upstream lock chamber 14 is located downstream of the river channel vertically below the bridge 1 , the downstream lock chamber 15 extends from downstream to upstream of the river channel vertically below the bridge 1 , and the pumping device 2 is arranged in the upstream lock chamber 14 .

[0050] The transport bottom plate 9 is horizontally arranged in the downstream lock chamber 15,

[0051] Others are the same as in Example 1.

[0052] Embodiment 2 can realize that the ship 12 traveling against the current in the river can also pass the bridge 1 with insufficient net height through the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com