Low-frequency and high-amplitude multi-functional table back compaction machine

A low-frequency, high-amplitude, multi-functional technology, applied in earth movers/excavators, soil protection, construction, etc., can solve the problems of hidden dangers in construction quality, limited working space, and high cost of construction, and achieve fast installation and movement. The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

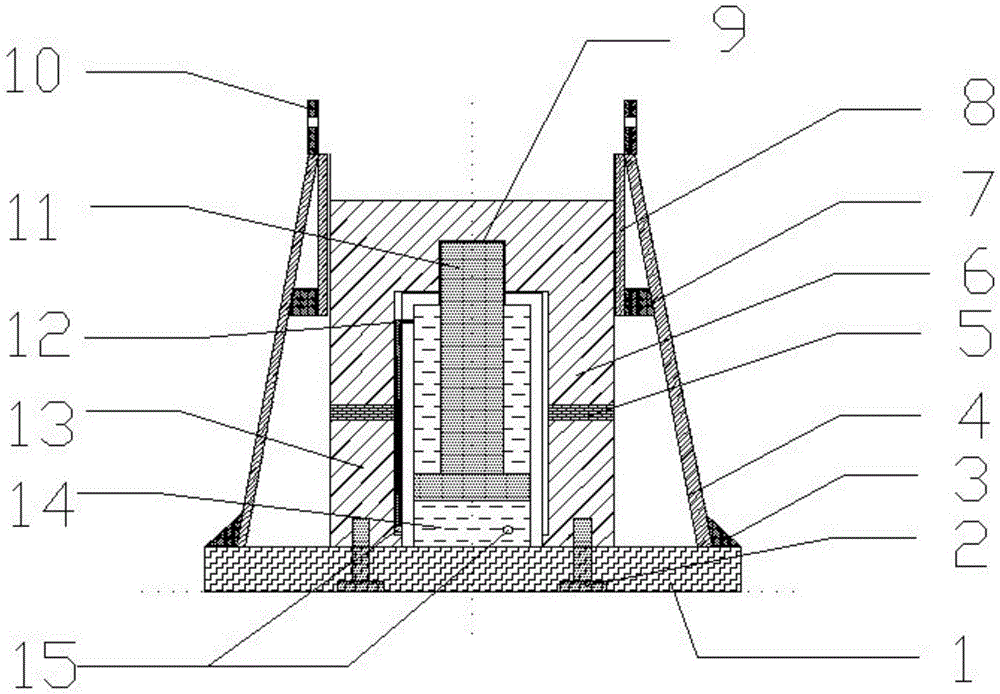

[0015] Such as figure 1 As shown, the low-frequency and high-amplitude multi-functional table back tamping machine tool includes a tamping base plate 1, a fixing bolt 2, a reinforcement connector 3, a side shell of the machine tool 4, a buffer rubber backing plate 5, a tamping iron 6, and a limit plate support 7 , tamping iron limit plate 8, jack telescopic slot 9, tamping equipment moving ring 10, hydraulic jack 11, tamping kinetic energy transmission block 13, hydraulic jack 11 includes tamping equipment internal jack hydraulic oil pipe 12, jack internal hydraulic oil 14 1. The upper and lower hydraulic oil in the jack enters and exits the external connection port 15.

[0016] The tamping base plate 1 and the tamping kinetic energy transmission block 13 are connected and fixed by fixing bolts 2; the periphery of the tamping base plate 1 and the machine tool side shell 4 are connected together through a reinforcement connector 3; the longitudinal section of the machine tool s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com