Stepping combed joint type self-joint-staggered flat formwork

A technology of planar formwork and staggered joints, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., which can solve the problems of non-recyclable machine-made panels, material waste, and low formwork support efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings of the description.

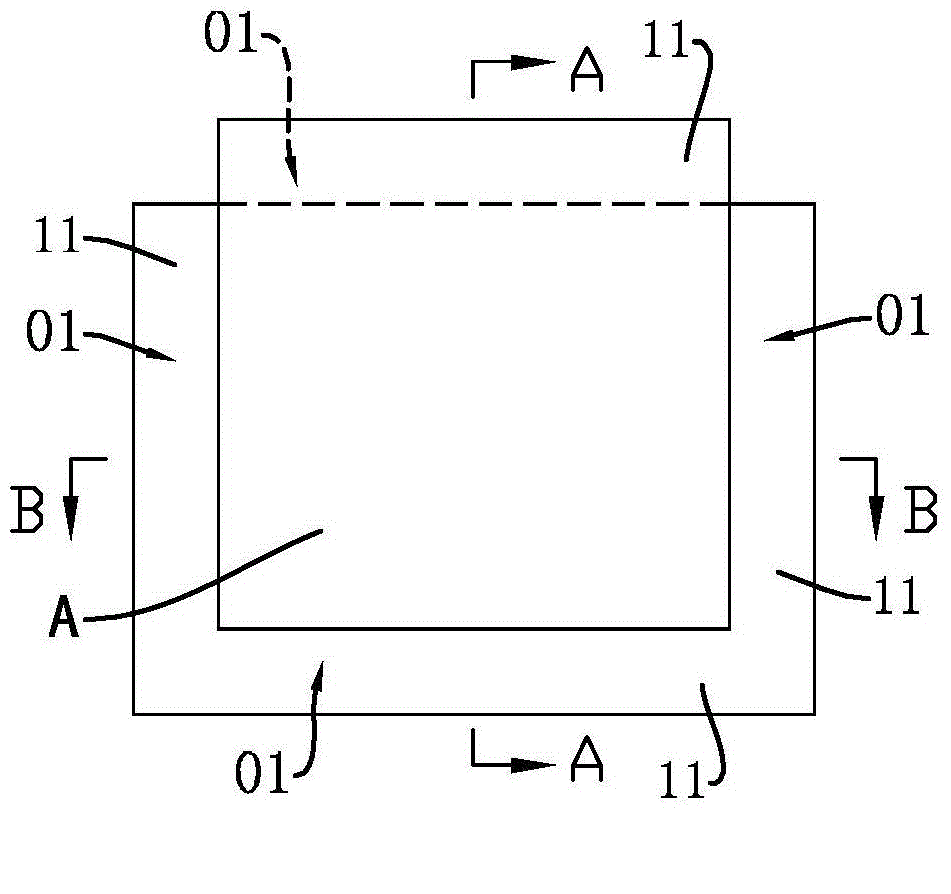

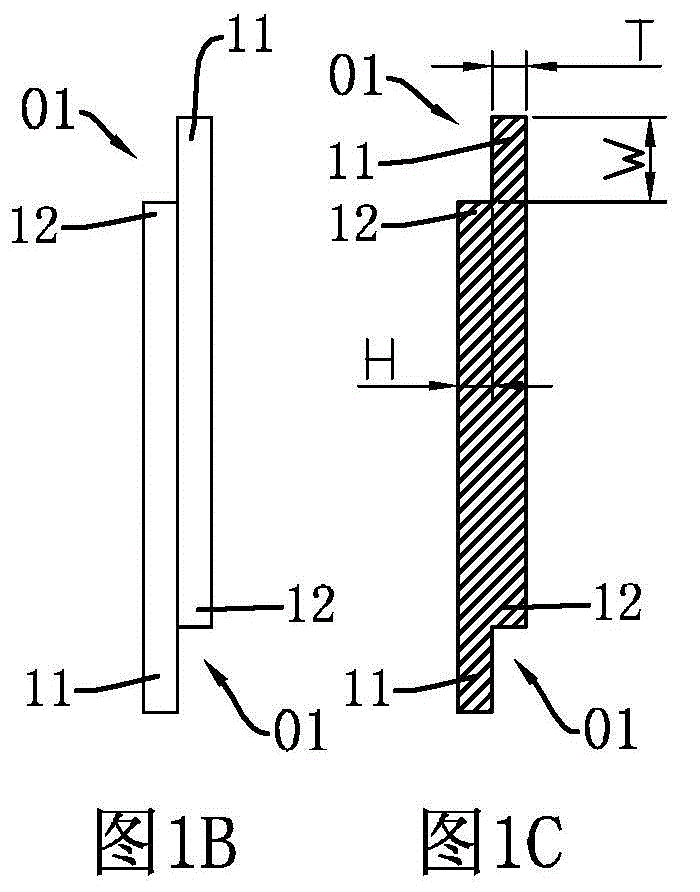

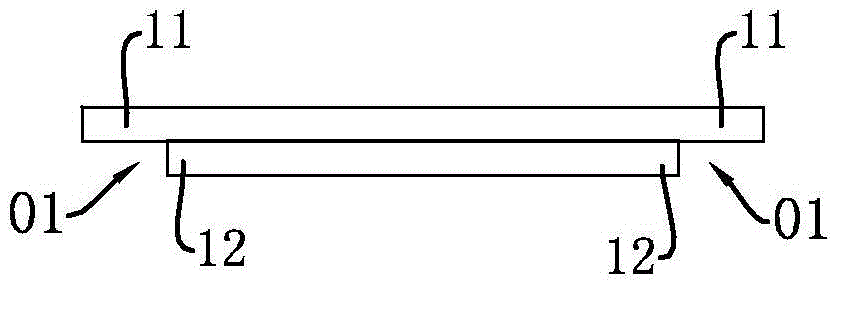

[0051] see Figures 1A-1E , Figure 2A-2E , the step tooth frame type self-staggered seam plane formwork of the present invention is respectively provided with a step tooth frame 01 at the peripheral edge of the plastic plane whole plate, although Figures 1A-1E and Figure 2A-2E The structure of the template shown in is different, but the structure of the frame expressed is the same, so the same label is used to indicate that a stepped frame 01 means that a staggered seam is set within the thickness range of the entire planar board. The step shape formed by the edge 11 and a staggered step 12 higher than the staggered edge, the thickness T of the staggered edge, and the step height H of the staggered step are respectively 1 / 2 of the thickness of the planar whole slab, and the planar whole slab The surrounding edges of each are respectively locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com