Anti-toppling carburetor structure based on external fuel oil container

A fuel container and carburetor technology, applied in carburetors, machines/engines, engine components, etc., can solve problems such as leakage, fuel leakage, flooding, etc., and achieve high reliability, fuel saving, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

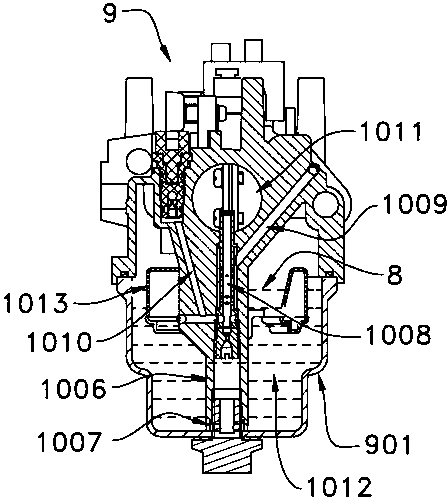

[0048] The working schematic diagram of the carburetor anti-dumping structure of the present invention is as follows: Figure 3 to Figure 4 shown.

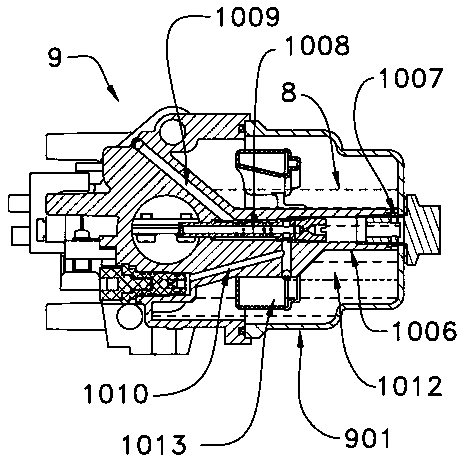

[0049] A fuel container 1 is arranged on the left side of the carburetor 10 , the bottom of the fuel container 1 communicates with the carburetor float chamber 1012 , and the top communicates with the carburetor balance hole 1015 through the hose 6 . Such as image 3 As shown, due to the high position of the fuel container 1 , when the carburetor 10 is in a vertical state, the fuel in the float chamber 1012 will basically not enter the fuel container 1 to avoid adverse effects on the work of the carburetor 10 . When the carburetor 10 tilts to the left to a horizontal state, such as Figure 4 As shown, part of the fuel in the float chamber 1012 enters the fuel container 1 to fill it up, the remaining fuel in the float chamber 1012 is less, and the fuel level 8 is lower than the bottom opening 1007 of the upper oil pipe, so the fu...

specific Embodiment approach

[0052] The carburetor anti-dumping structure of the present invention is that a fuel container 1 is respectively arranged on the left and right sides of the carburetor 10, and the specific implementation method is as follows:

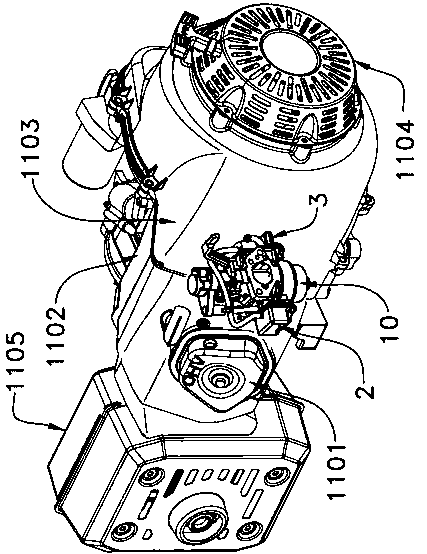

[0053] The anti-dumping structure of the carburetor is composed of the left fuel container 2, the right fuel container 3, the sealing ring 4, the screw 5, the hose 6 and the cross 7.

[0054] The left and right sides of the oil cup 1001 of the carburetor 10 are respectively provided with a screw column 1002, and each screw column 1002 is provided with a front boss 1003 and a rear boss 1004 on both sides, and an opening is arranged in the middle of the boss. Hole 1005. A fuel container is respectively arranged on the left and right sides of the oil cup 1001 of the carburetor 10: a left fuel container 2 and a right fuel container 3, and the left fuel container 2 is composed of a left oil box 206 and an oil cover 207, The right fuel container 3 is compose...

Embodiment 2

[0066] Compared with the first embodiment, the difference of the second embodiment is that the top of the fuel container 1 communicates with the float chamber 1012 on the other side of the carburetor 10 .

[0067] Such as Figure 22 As shown, the top of the fuel container 1 arranged on the left side can communicate with the float chamber 1012 on the right side of the carburetor 10 through the hose 6 . Such as Figure 23 As shown, when the carburetor 10 tilts to the left to be horizontal, there will be a large cavity on the right side of the float chamber 1012 of the carburetor 10, allowing the air in the left fuel container 2 to enter the right side of the float chamber 1012 through the hose 6, Free flow of fuel between the fuel container 1 and the float chamber 1012 can be realized.

[0068] The specific implementation manner of embodiment two is as follows:

[0069] The anti-dumping structure of the carburetor 10 is composed of the left fuel container 2, the right fuel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com