A travel control universal strain angle hydraulic cylinder

A hydraulic cylinder and hydraulic technology, applied in the field of travel control universal strain angle hydraulic cylinder, can solve problems such as abnormal work, deformation of key components, oil leakage of products, etc., and achieve the effect of a flexible working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

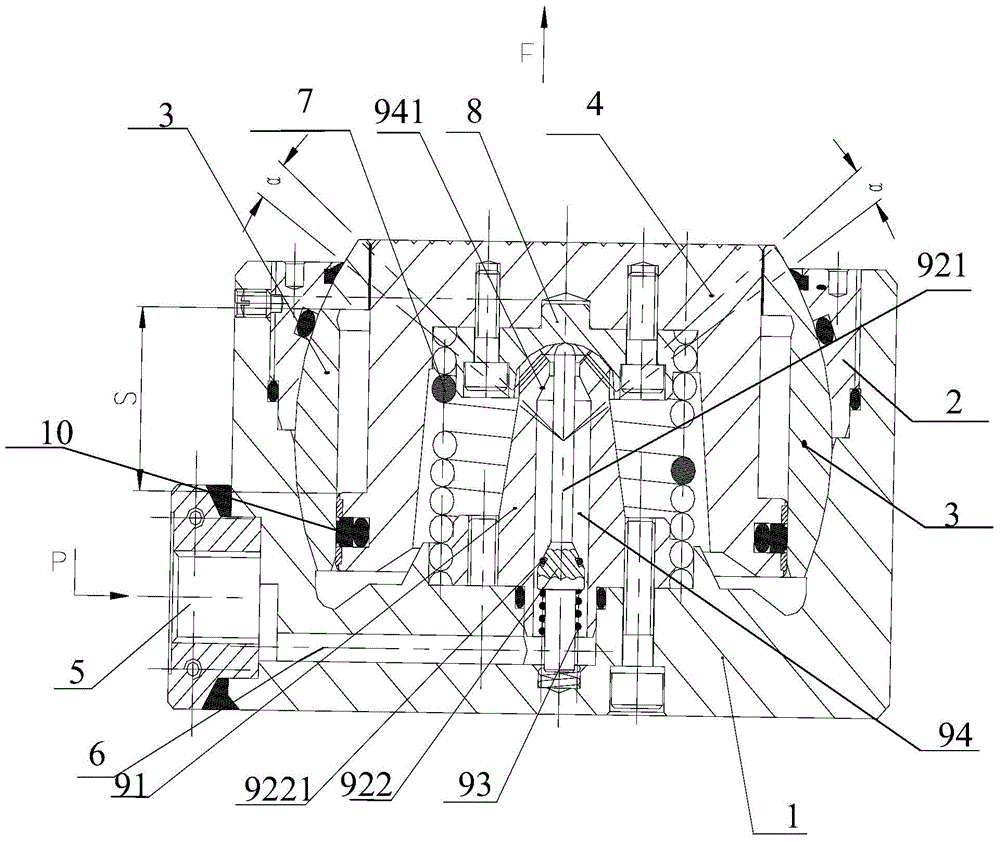

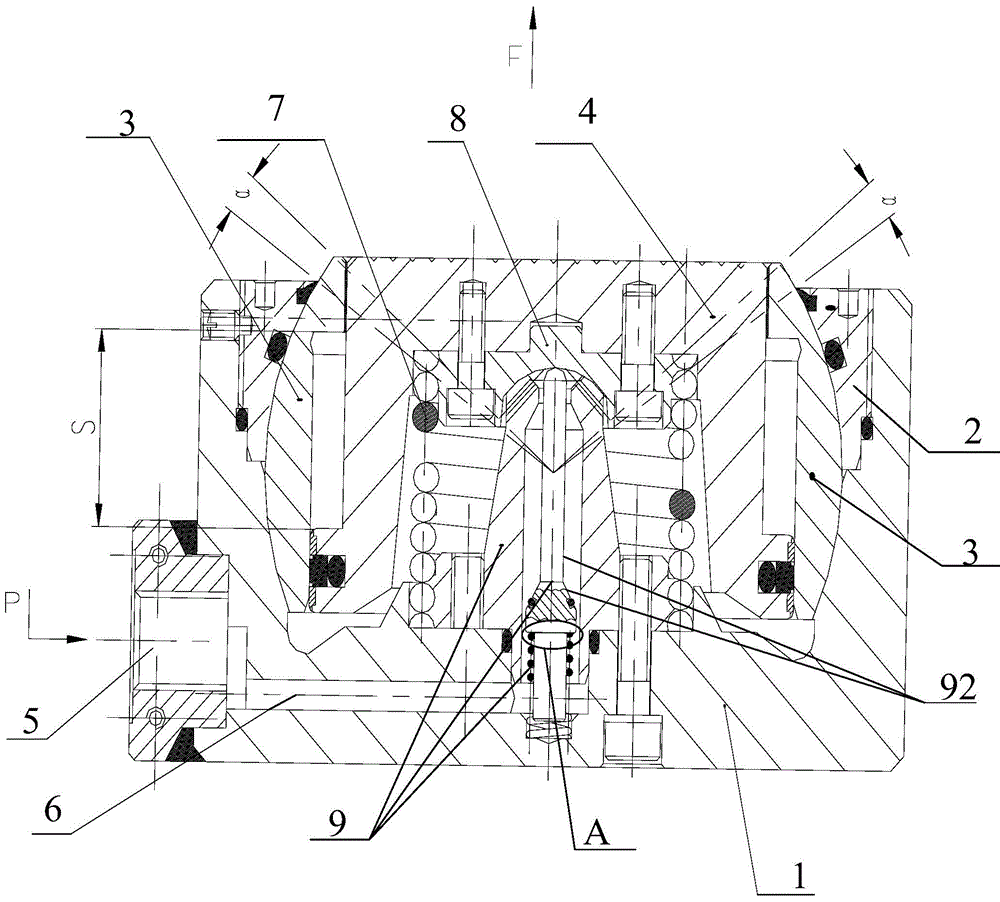

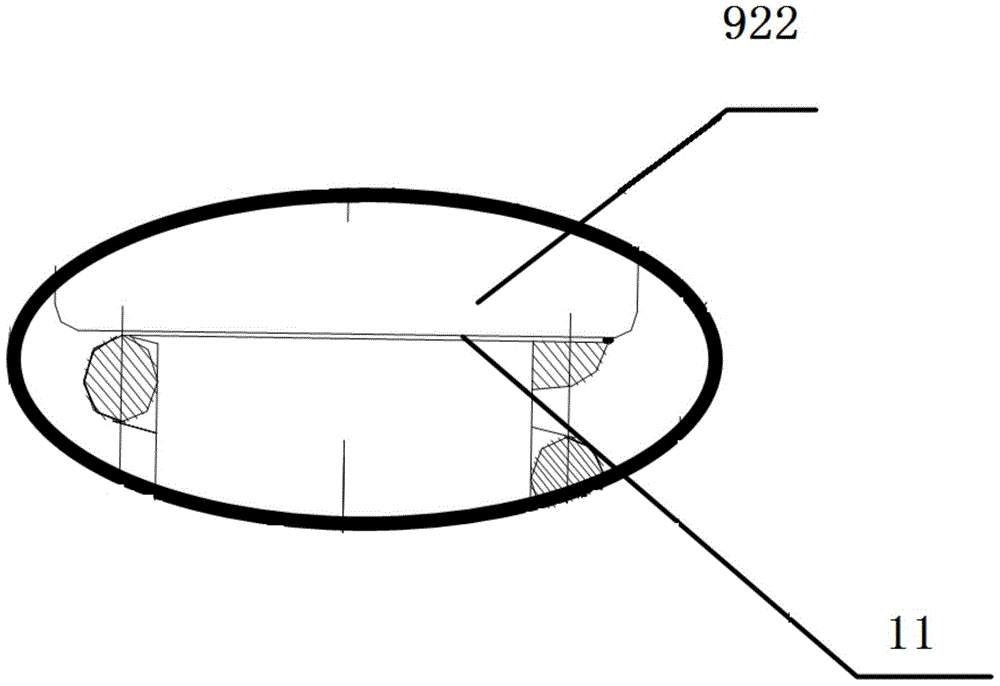

[0034] like figure 1 , 2 As shown, a typical embodiment of the structure of a line-controlled universal strain angle hydraulic cylinder of the present invention includes a casing 1, a gland 2, a cylinder body 3 and a piston rod body 4, and a pressure input interface 5 is provided on the outside of the casing 1. And the flow channel 6, which has an inner spherical cavity formed with the gland, which is matched with the outer spherical cylinder, and the outer spherical cylinder is provided with a cylindrical cavity along the direction of the central axis. A piston rod body capable of linear reciprocating motion is fitted in the cavity, and the upper part of the cylinder body is higher than the end face of the gland. The piston rod and the cylinder are on the plane perpendicular to the central axis, and the free universal 360° strain outputs the force F of the angle α.

[0035] The piston rod body 4 has an inner blind accommodating cavity, and the accommodating cavity is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com