Machine needle driving mechanism for spatial four-rod embroidery machine

A driving mechanism, embroidery machine technology, applied in the direction of embroidery machine mechanism, embroidery machine, mechanical equipment, etc., can solve the problems such as strict limitation of use scope, difficulty in replacement, and difficulty in installation of power shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

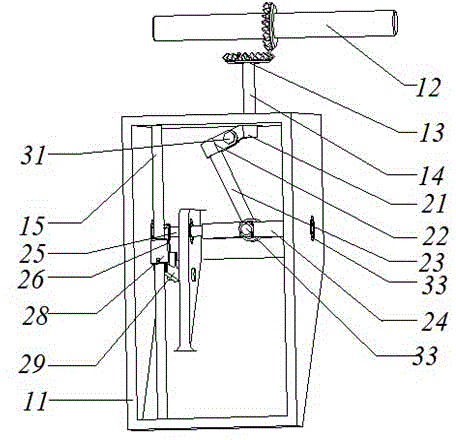

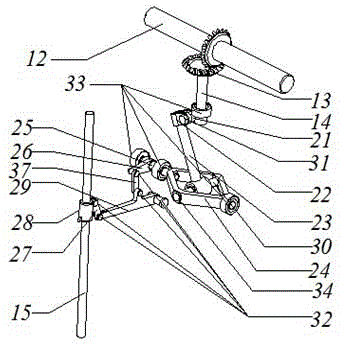

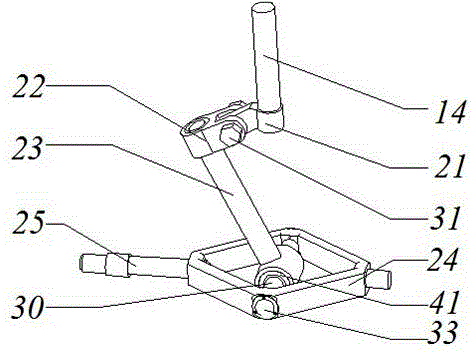

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] like Figure 1-5 As shown, the needle driving mechanism of the space four-bar embroidery machine of the present invention mainly includes a power input part, a casing 11, a driving mechanism, and a power output part. The power input part is mainly composed of a main shaft 12 and a pair of bevel gears 13 installed on the main shaft 12 and the driving rod 14 . The lower end of the drive rod 14 is fixed with a ring joint 21 , and the ring joint 21 and the adapter 22 are fixed by a nut screw 31 . The installation angle between the ring joint 21 and the adapter 22 can be changed arbitrarily to meet the installation requirements. After the installation is completed, the ring joint 21 and the adapter 22 must be fixed.

[0020] The driving mechanism includes a space four-bar part and a planar four-bar part, and the two parts are connected by a swing shaft 25 . The space f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com