Energy-saving quick defroster

An energy-saving and fast technology, applied in the field of heat exchange, which can solve the problems of large temperature fluctuations on the evaporator side, falling frost layer, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred implementation of the present invention and its modified examples are described in detail below in conjunction with the accompanying drawings by way of illustration rather than limitation of the scope of protection required by the inventive idea.

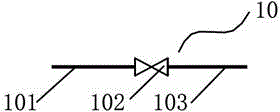

[0025] figure 1 It is a schematic diagram of the working principle of the high-pressure gas bypass assembly for defrosting of the energy-saving fast device of the present invention. The high-pressure gas bypass assembly 10 mainly includes: an intake pipeline 101 , a valve 102 , and an outlet pipeline 103 .

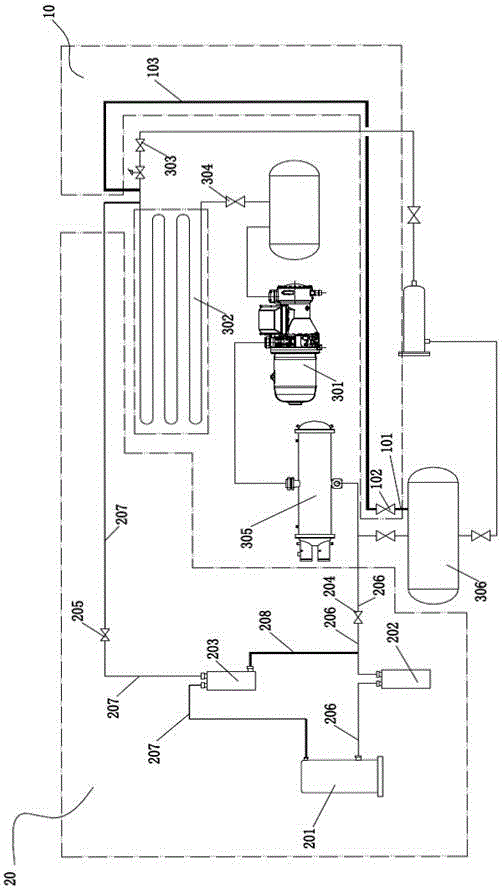

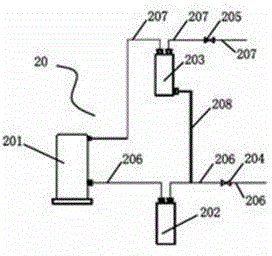

[0026] figure 2 It is a schematic diagram of the working principle of the defrosting compressor unit as the energy-saving fast device defrosting of the present invention. Defrost compressor unit 20 mainly includes: defrost compressor (201), gas-liquid separator 202, oil separator 203, suction valve 204, exhaust valve 205, suction pipeline 206, exhaust pipeline 207, return Tubing 208.

[0027] image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com