A method for burning and utilizing scrapped granular propellants

A propellant and granular technology, which is applied in the field of combustion and utilization of scrapped granular propellants, can solve problems such as energy waste, and achieve the effects of solving energy waste, improving resource utilization efficiency, and controllable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

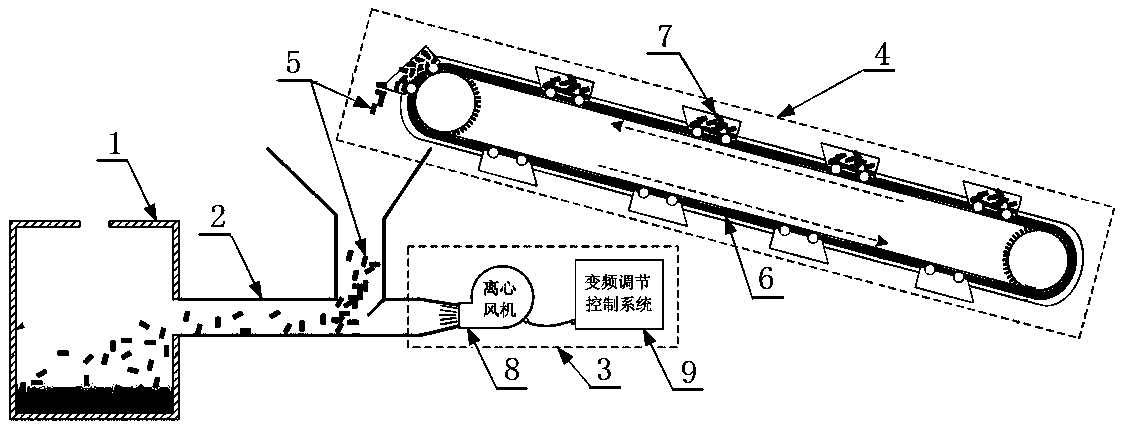

[0017] Such as figure 1 As shown, the waste granular propellant combustion utilization method of the present invention comprises the following steps:

[0018] (1) A conveyor belt 6 is installed and a number of feeding trolleys 7 that move synchronously with the conveyor belt are installed on the conveyor belt, and the granular propellant 5 is placed in the feeding trolley 7;

[0019] (2) A feed pipe 2 for receiving granular propellants is provided below the end of the conveyor belt 6. The upper inlet of the feed pipe 2 is opened upwards, the middle part is bent and an air port is opened, and the air port is connected with an air duct. The end of the air duct is connected with a centrifugal fan 8 that blows air into the air duct; the upper inlet of the feeding pipeline accepts the granular propellant 5 that falls at the end of the conveyor belt as the conveyor belt moves;

[0020] (3) Set up a combustion container 1 that utilizes the granular propellant 5 to burn heat energy, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com