Blast furnace raceway imaging system and imaging method

A technology of an imaging system and an imaging method, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of inability to understand the bottom of the blast furnace, low accuracy, and the lack of an overall intuitive understanding of the gyroscope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

[0035] Imaging system and imaging method of blast furnace swirling zone of the present invention

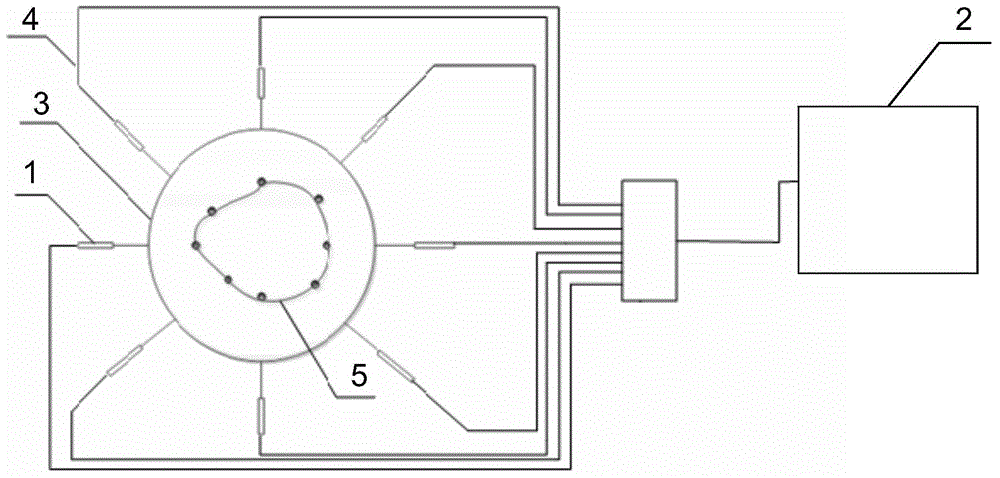

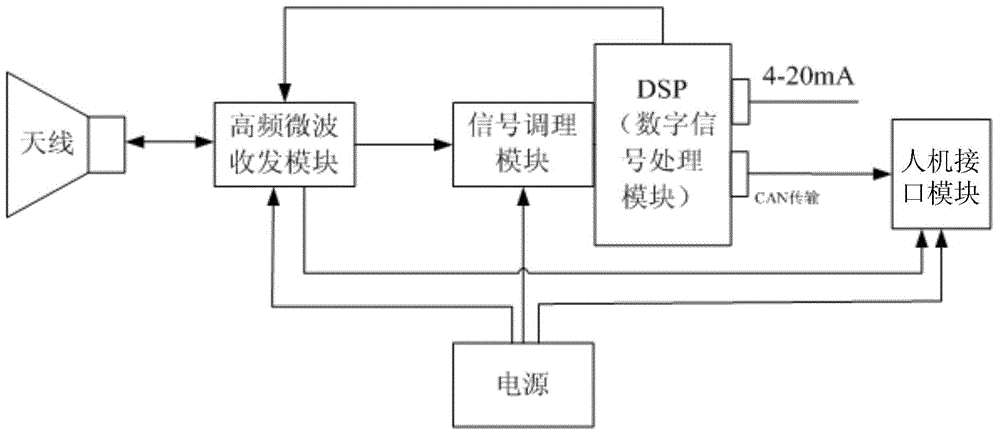

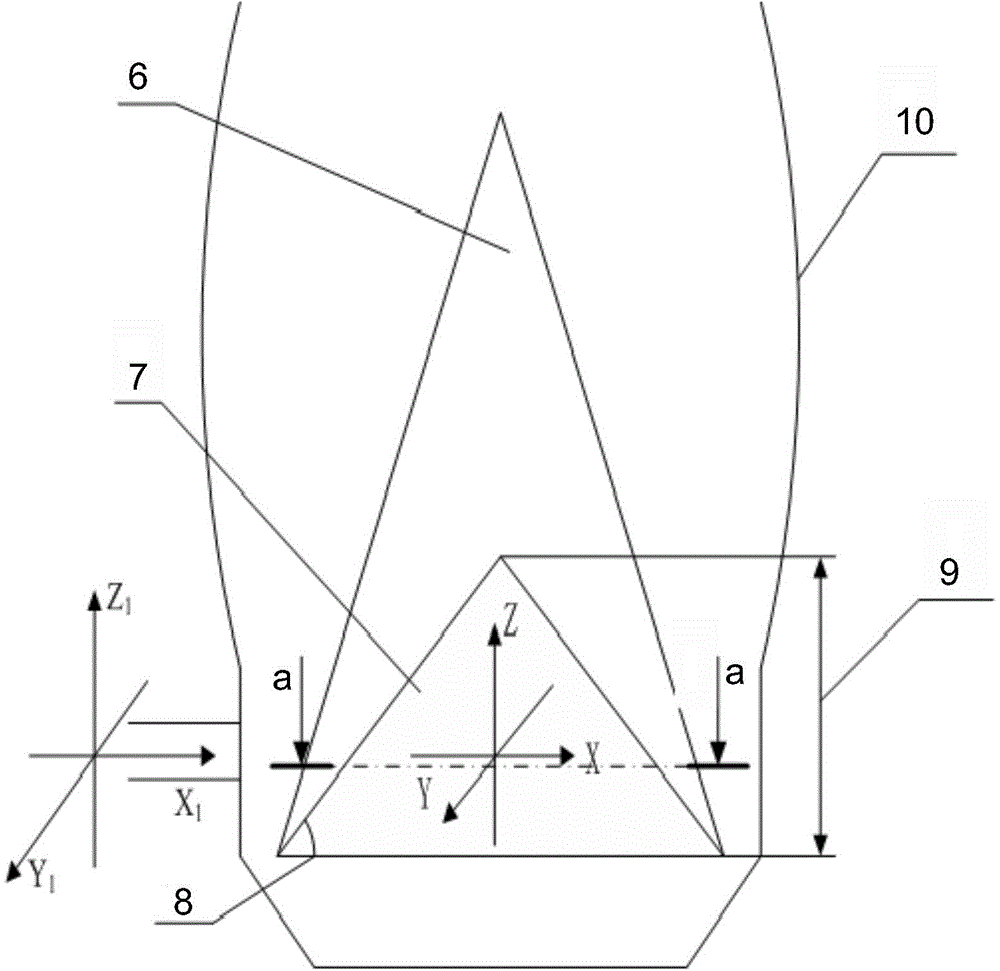

[0036] Please combine figure 1 , figure 2 As shown, the blast furnace whirling zone imaging system of the present invention mainly includes a microwave measuring instrument 1 for depth measurement of the blast furnace whirling zone and a three-dimensional imaging computer 2 for the dead material column in the zone. The microwave measuring instrument 1 includes an antenna, a high-frequency microwave transceiver module, and a signal The conditioning module, digital signal processing module and man-machine interface module, the high-frequency microwave transceiver module transmits high-frequency microwaves to the blast furnace 3 gyration zone through the antenna, and receives the reflected echo, which is converted into zero intermediate frequency by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com