Detecting system for gas instrument

A detection system and gas technology, used in liquid/fluid solid measurement, instruments, measurement devices, etc., can solve problems such as the decline of vacuum pumping ability, verification uncertainties, errors, etc., to reduce the change of temperature difference and improve the controllability performance and meet the precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

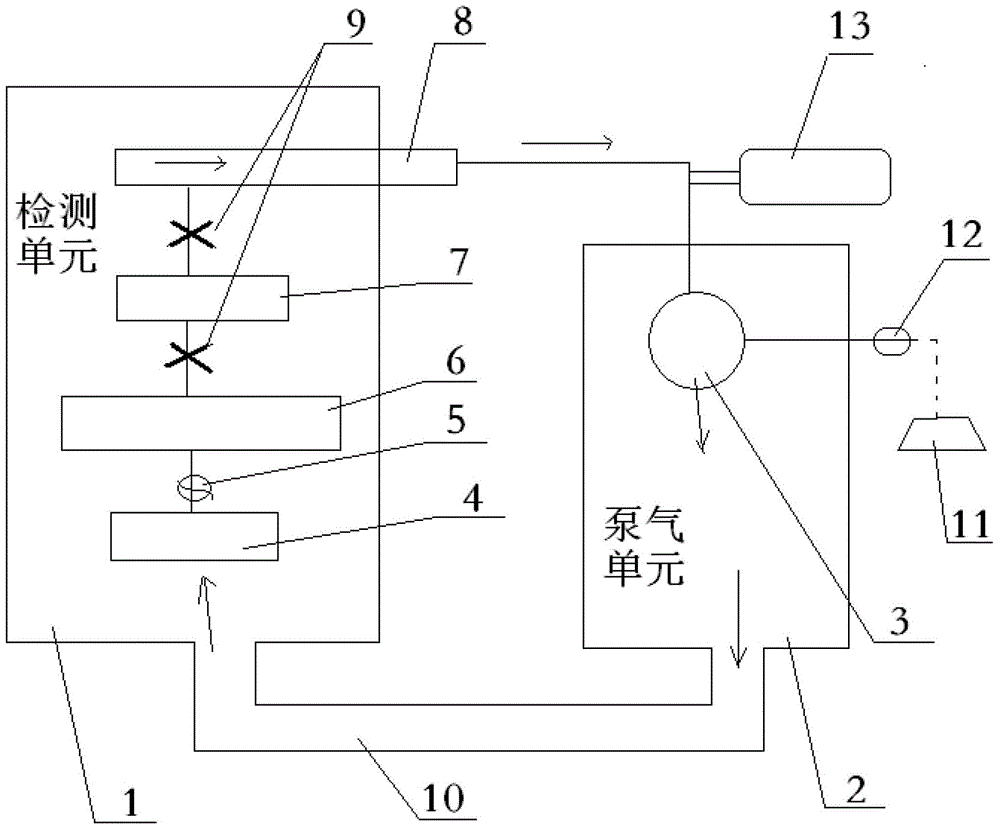

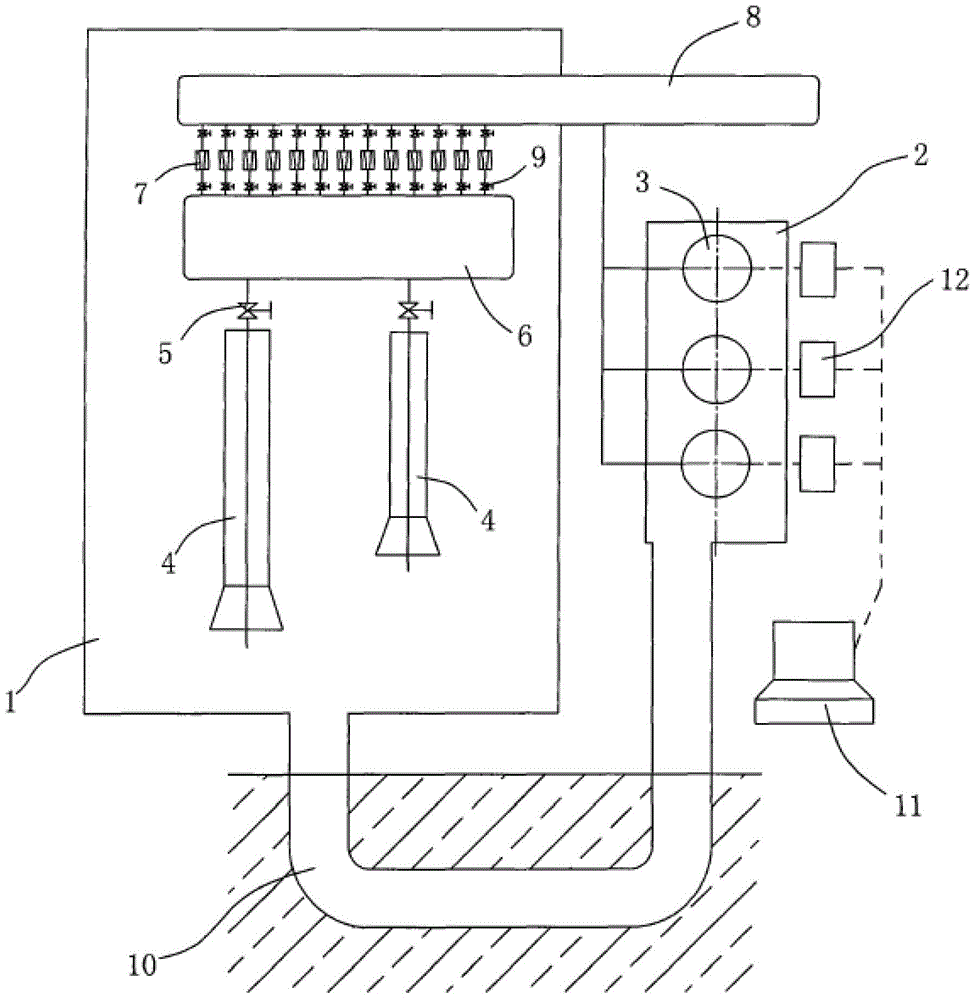

[0029] Such as Figure 1-2 Shown, the present invention is used in the detection system of gas meter,

[0030] A detection system for a gas meter, comprising a detection unit and a pumping unit; a negative pressure pipeline and an outlet pipeline are connected between the detection unit and the pumping unit, and the detection unit includes a detection platform, a hysteresis stop container, sonic nozzle; the pump air unit includes a vacuum pump, one end of the vacuum pump is connected to the outlet pipeline, and the other end of the vacuum pump is connected to the negative pressure pipeline; the outside of the vacuum pump is connected to a frequency conversion control device, and the operating speed of the vacuum pump is intelligently controlled by the frequency conversion control device , the frequency conversion control device is connected t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap