Process layout method for conventional hypersonic speed wind tunnel

A hypersonic, process layout technology, applied in the field of aerodynamics, can solve the problems of high dynamic sealing requirements, limit the wind tunnel simulation ability, increase the structural complexity of the test section, etc., achieve the effect of reliable vacuum sealing and improve the test simulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

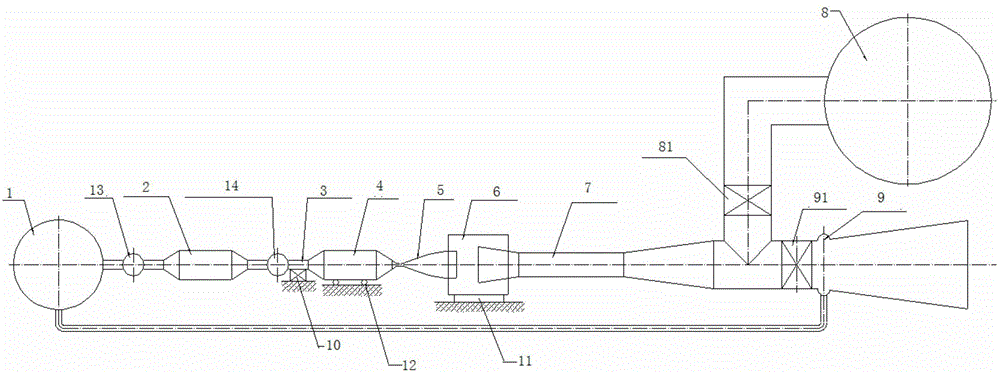

[0019] In the process layout of the existing wind tunnel, the fixed support bearing the axial force is placed under the front chamber, and the space for replacing the nozzle is obtained by moving the test section back and forth, which increases the structural complexity of the test section and needs to solve the problem of the test section. Section movement, positioning and sealing and other related issues; in addition, the super-expansion section needs to be equipped with a telescopic structure, and its sliding seal cannot meet the higher vacuum requirements. In terms of operation mode, existing wind tunnels only use blowing or blowing suction, and the height simulation capability of wind tunnels is limited. For this, see figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com