A pneumatic device for motorcycle engine detection and positioning

An engine and pneumatic technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve the problems of consistent production of engines, poor engine reliability, inconsistent test results, etc., and achieve dismantling The effect of installing the engine is convenient, reliable, and the circuit is clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

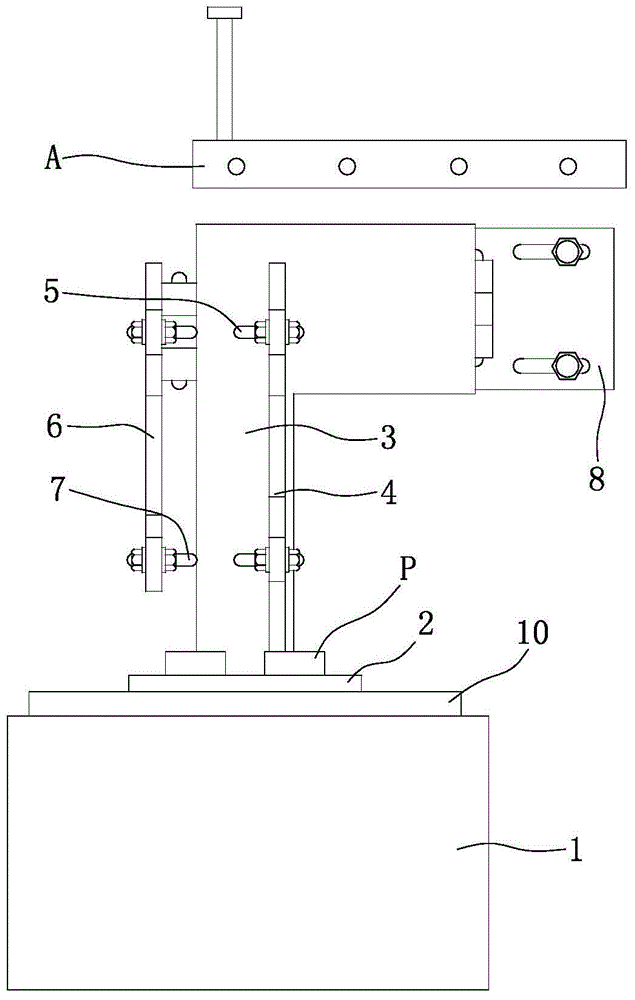

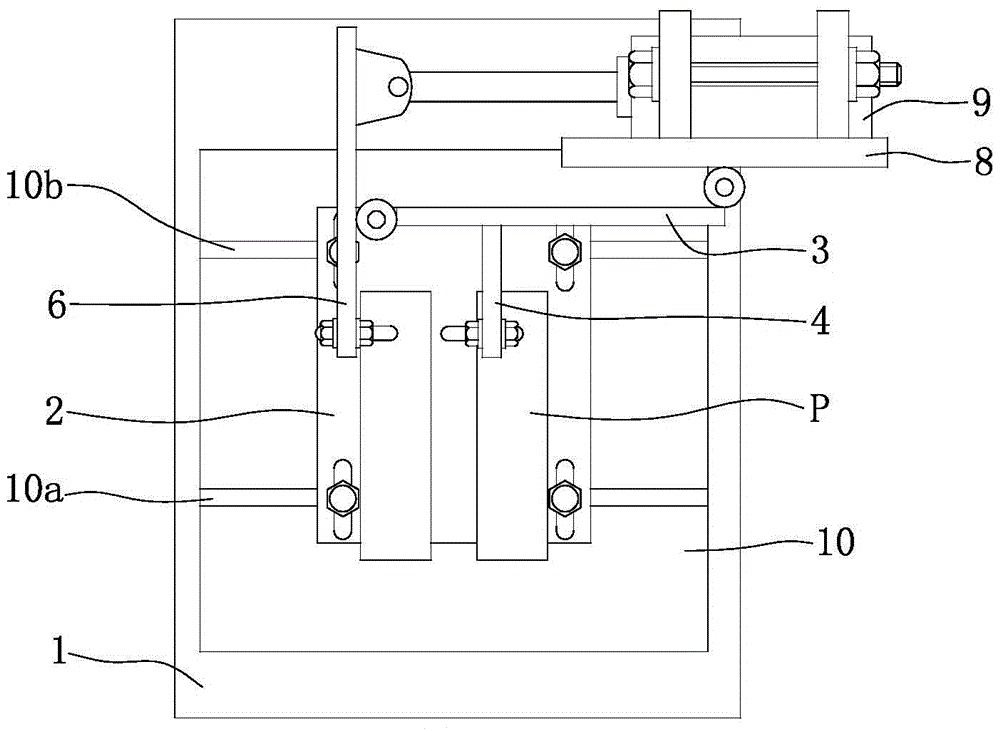

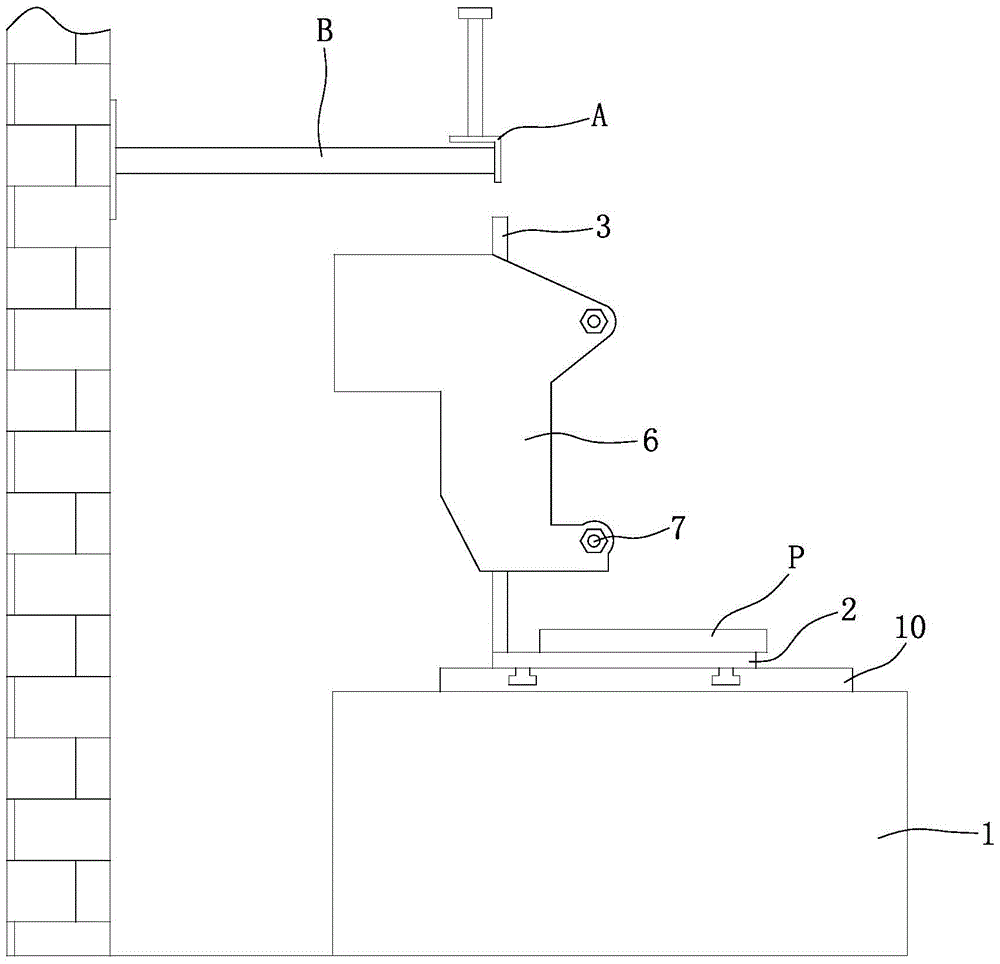

[0020] Such as figure 1 , figure 2 , image 3 As shown, the base 1 is a cuboid and fixed on the ground. The backing plate 10 is fixedly installed on the top surface of the base 1, the backing plate 10 is a rectangular steel plate, and the front transverse groove 10a and the rear transverse groove 10b parallel to each other are provided on the backing plate 10, and each transverse groove starts from the left end of the backing plate 10. Pass through to the right end. A bottom plate 2 is arranged on the backing plate 10 , the bottom plate 2 is preferably a rectangular steel plate, and the bottom surface of the bottom plate 2 is attached to the top surface of the backing plate 10 . The bottom plate 2 is connected to the backing plate 10 through two front bolts and two rear bolts. The four bolts are distributed in a rectangle, and the lower ends of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com