Method for measuring incidence point, incidence angle and delay of small-angle longitudinal wave angle probe for porcelain insulator

A ceramic insulator, small-angle technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of narrow maximum amplitude swimming range, inability to measure time delay and longitudinal wave incident angle at the same time, to avoid poor repeatability , The system error is small, the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

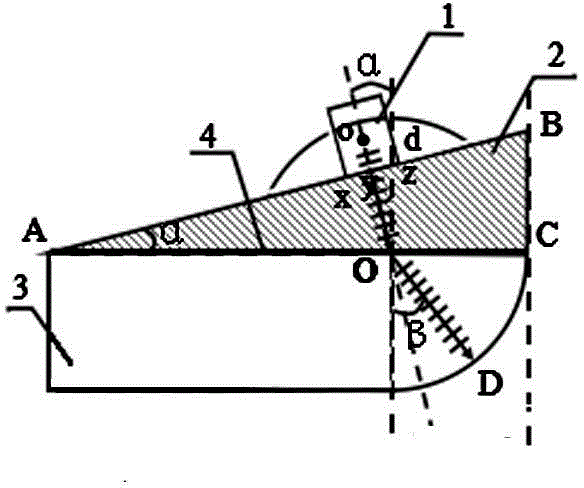

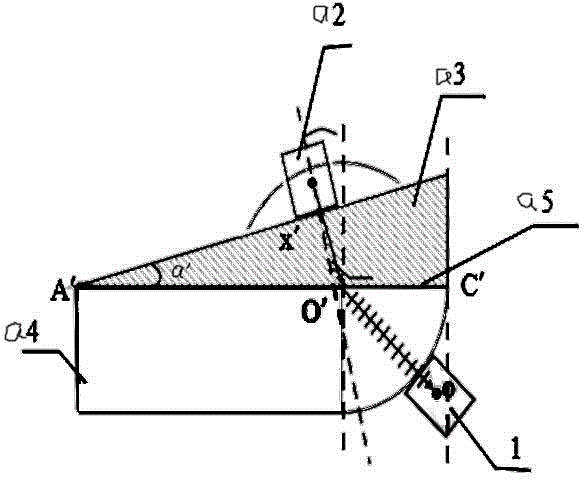

[0015] The present invention is a method for measuring the incident point, time delay and incident angle of a small-angle longitudinal wave oblique probe for porcelain insulators. The steps are as follows (see attached figure 1 , 2 )

[0016] (1) Measure the incident point and delay of the reference straight shear wave probe:

[0017] Select a straight shear wave probe as the reference shear wave probe 1. Then make a special test block for transverse wave straight probes, its upper part: the material is a right-angled triangular machine glass block 2 of a certain size and a certain inclination angle made of organic glass, and its lower part: the material is a boat shape (rectangle and 1 / 4 circle) of steel block 3 Shaped combination), the plexiglass block 2 and the steel block 3 are tightly bonded with an extremely thin aluminum foil, copper foil or phenyl salicylate as the transverse wave coupling agent 5, so that the ultrasonic transverse wave can pass through the combinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com