Fuel gas sensor calibration method based on CAN bus

A gas sensor and CAN bus technology, applied in the field of gas sensor calibration based on CAN bus, can solve the problems of difficult calibration, high calibration cost, low calibration efficiency, etc., and achieve the effect of reducing wiring harnesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

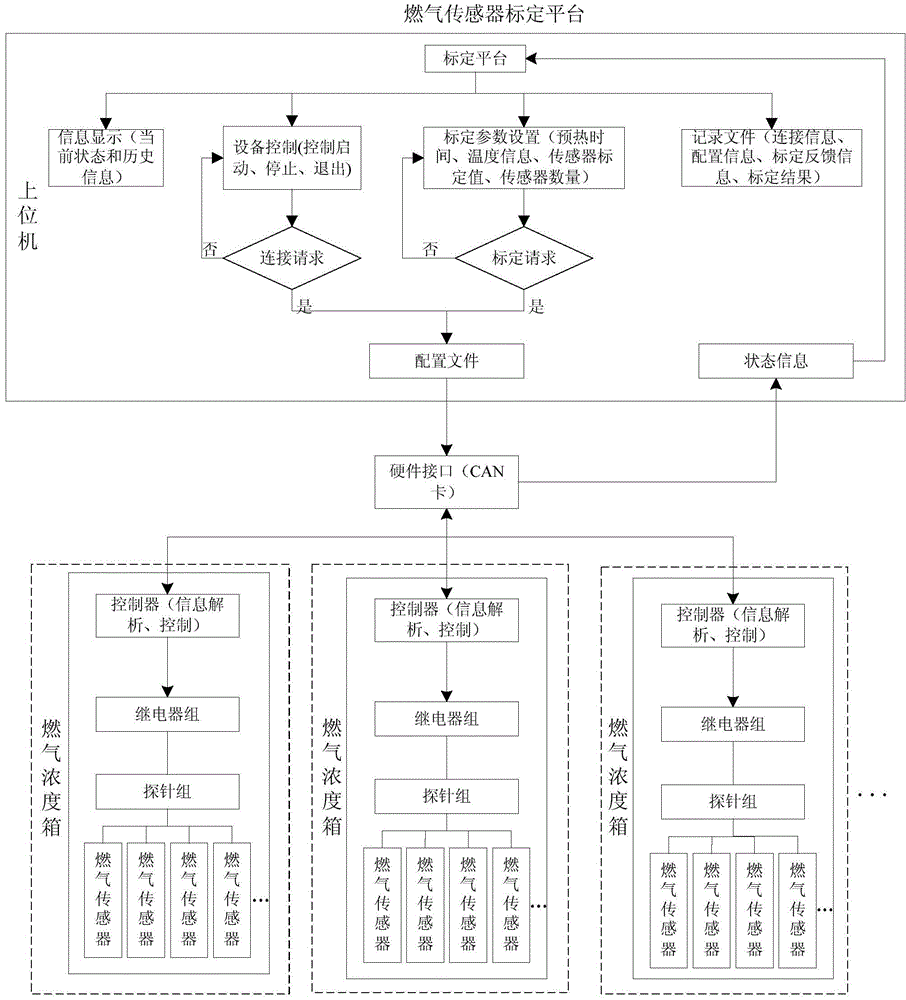

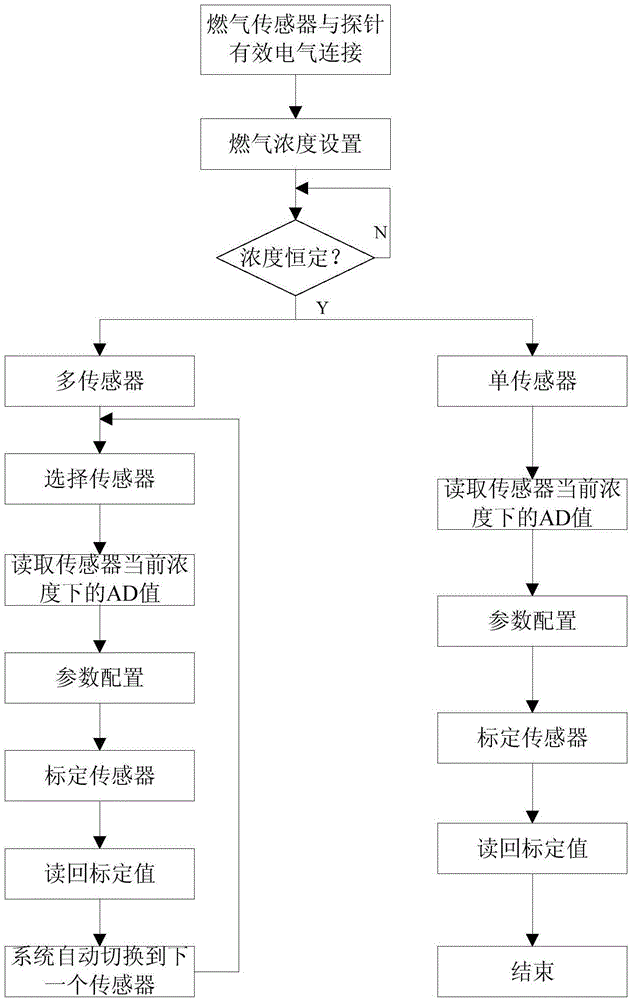

[0022] Aiming at the difficult, low-efficiency and expensive sensor calibration in the current gas alarm system, the present invention provides a gas sensor calibration method based on the CAN bus, which can realize fast, efficient and low-cost calibration of the gas sensor. Make up for the deficiencies in the existing calibration equipment. This calibration follows the national measurement and testing regulations JJG 693-2004 to calibrate the alarm value of the gas sensor. The calibration method can flexibly select multiple parameters of the sensor and perform effective calibration. The method transmits information during the calibration process through the CAN bus, uses a closed-loop control strategy to calibrate the gas sensor, and provides effective feedback on the calibration results. Generate record files for users to review and ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com