Mirror automatic folding, positioning, splicing film condenser structure

A technology for positioning and splicing and condensing mirrors, which is applied in the field of space optics, can solve the problems that the gas-filled hardened film structure is easily broken down by particles, is difficult to maintain the expected main mirror surface shape, and has low reliability, so as to improve the reliability of the deployment structure and avoid deployment failure. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

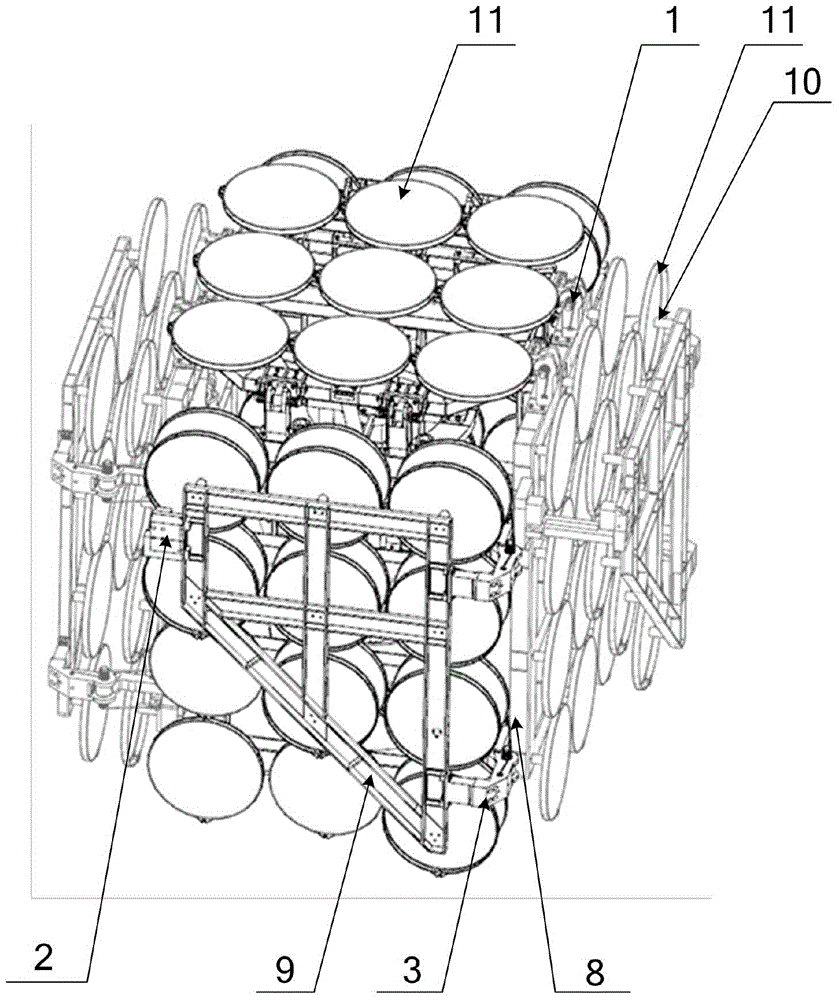

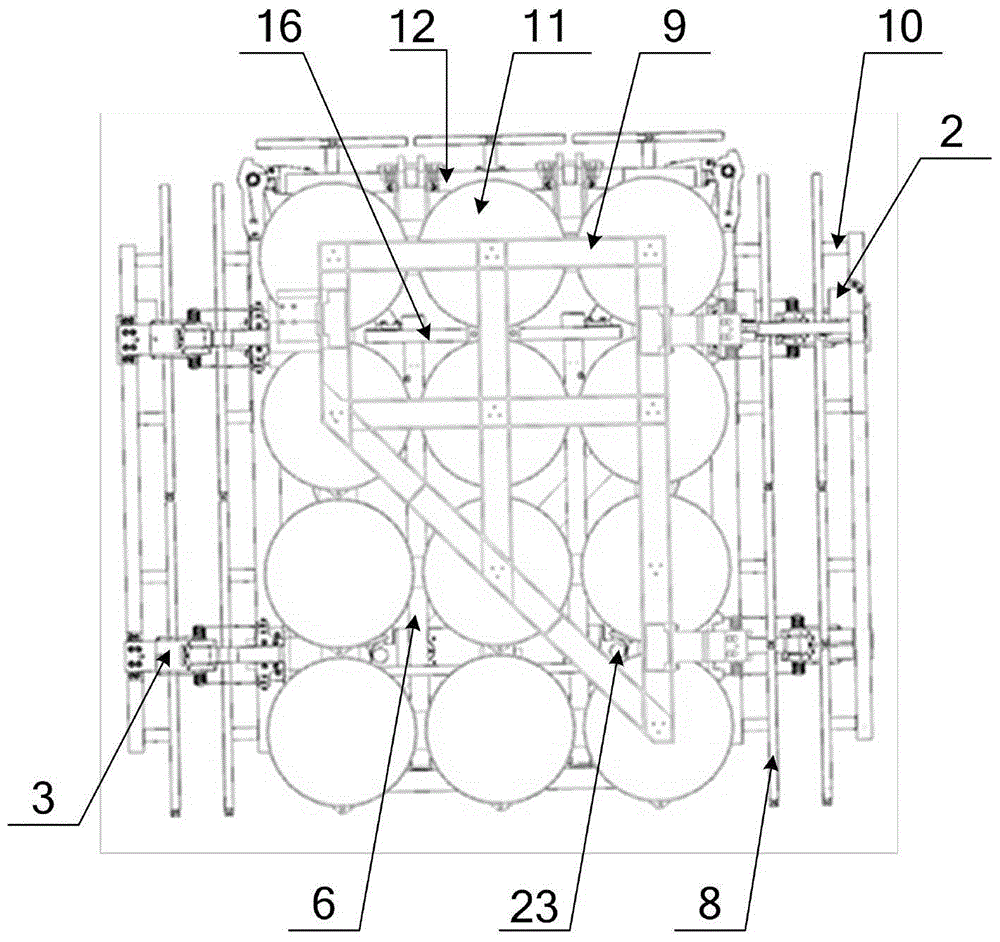

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

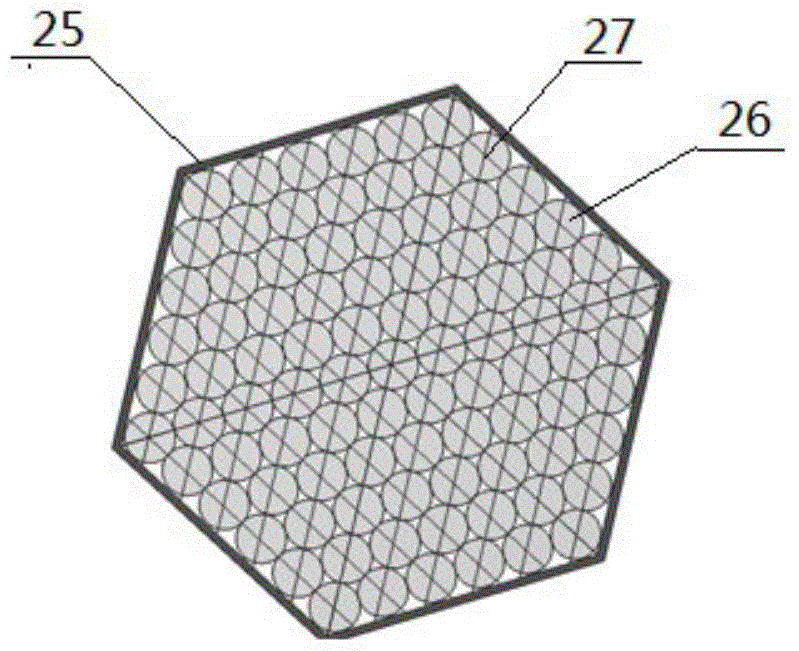

[0043] Such as Figure 2 to Figure 7 As shown, the mirror surface of the present invention automatically folds and expands and positions the spliced film condenser structure, which is mainly composed of a 90° hinge 1, an electric control lock 2, a 180° hinge 3, a motor 4, a turntable connection support seat 5, a sliding guide rod 6, and a hinge rod 7. Inner plate 8, outer plate 9, film mirror adjustment frame 10, film mirror 11, upper plate 12, truss bar 13, inner plate hinge support 14, lead screw limit sleeve 15, truss bar load-bearing base 16, Motion leading screw 17, leading screw sliding nut 18, motor seat adjustment pad 19, motor seat 20, sliding guide ring 21, oil-free bushing 22, hinged pole rotating shaft 23 and limiter 24 form.

[0044] Such as Figure 5 and Figure 6 as shown ( Figure 5 and Figure 6Both the two inner plates 8 and the two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com