Developing roller and process cartridge

A technology for developing rollers and process boxes, which is applied in the field of parts and components, and can solve problems such as the large diameter of the metal mandrel and restrictions on the selection of materials for the foaming layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

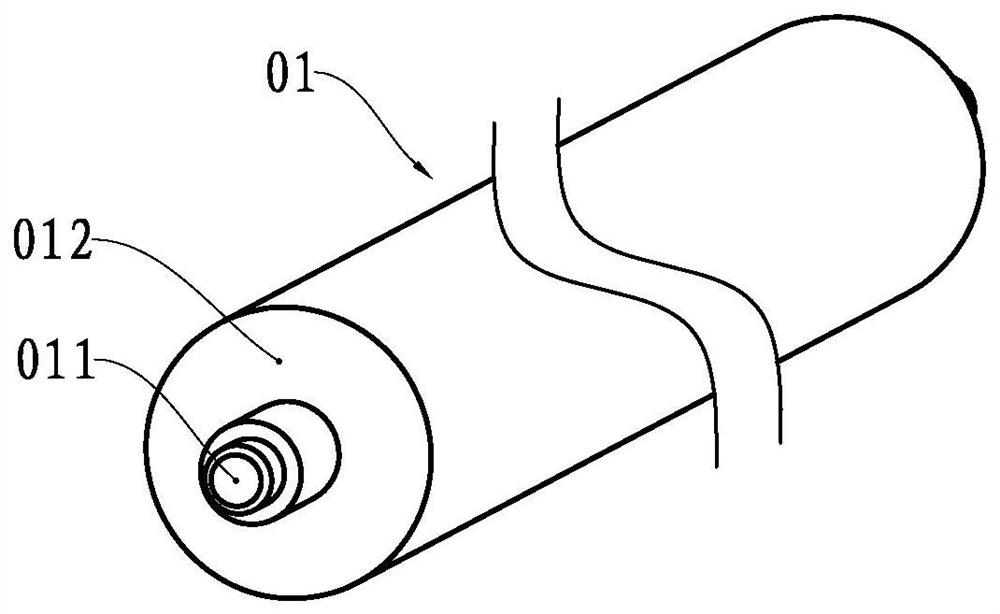

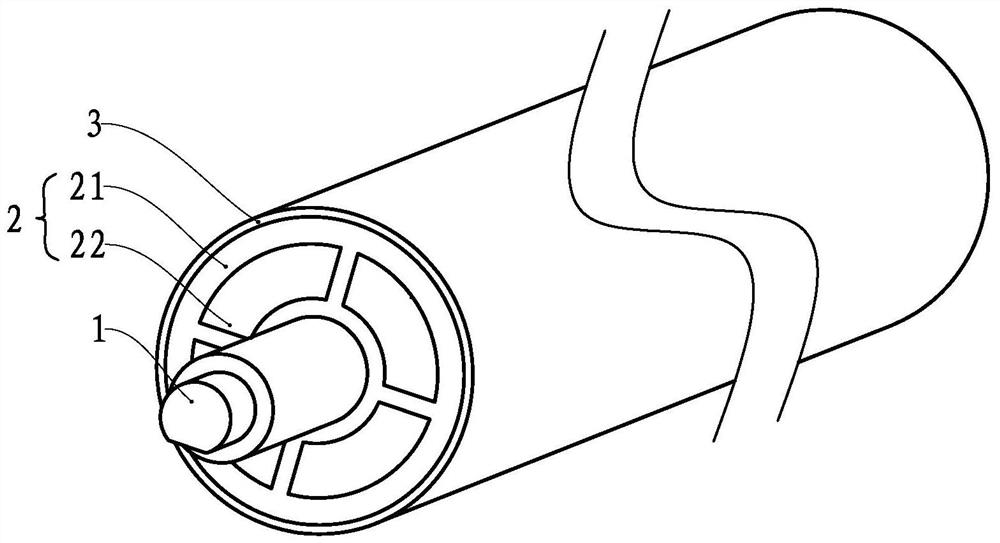

[0029] see image 3 , The developing roller is composed of a metal mandrel 1, an intermediate layer 2 and a conductive elastic layer 3, the intermediate layer 2 is composed of a supporting structure 21 and a conductive structure 22, the intermediate layer 2 is set outside the metal mandrel 1, and the conductive elastic layer 3 is set in the middle Layer 2 outside.

[0030] see Figure 4 to Figure 6 , the support structure 21 is composed of an inner support cylinder 211, an outer support cylinder 212, and spokes 213 connecting the inner support cylinder 211 and the outer support cylinder 212; Extending to the other axial end; the inner support cylinder 211 is formed with 8 rows of first through holes 2111 arranged radially along the developing roller, and the outer support cylinder 212 is formed with 8 rows of second through holes arranged radially along the developing roller 2121; the conductive structure 22 is a conductor filled between the inner support cylinder 211 and th...

no. 2 example

[0034] As a description of the second embodiment of the developing roller of the present invention, only the differences from the first embodiment of the developing roller described above will be described below.

[0035] A hollow metal mandrel is used instead of a solid metal mandrel.

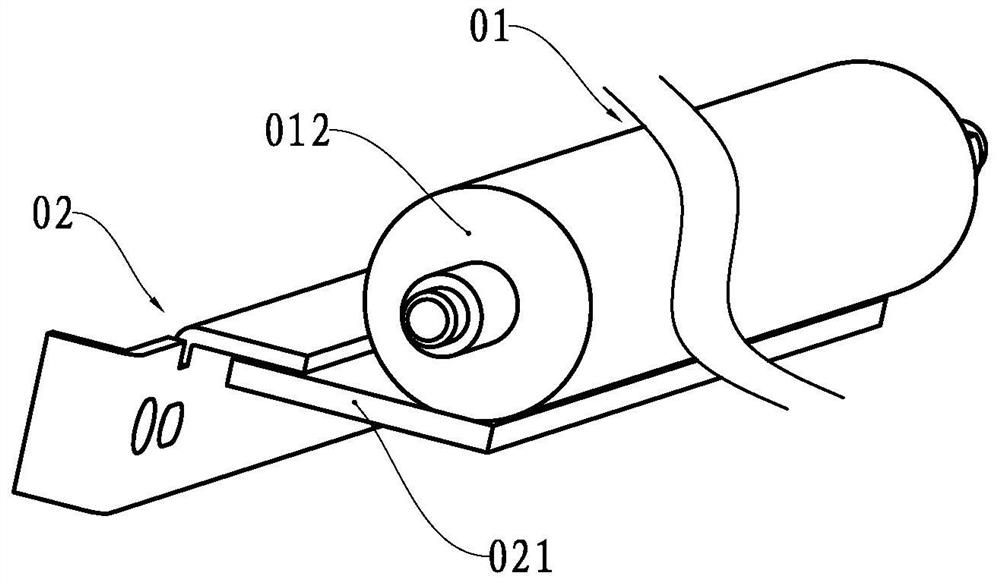

[0036] Process cartridge first embodiment

[0037] The process cartridge has a casing and a developing roller rotatably supported on both ends of the casing, wherein the developing roller is the developing roller in the first embodiment of the above-mentioned developing roller.

[0038] Process cartridge second embodiment

[0039] As a description of the second embodiment of the process cartridge according to the present invention, only the points of difference from the above-mentioned first embodiment of the process cartridge will be described below.

[0040] Wherein the developing roller adopts the developing roller in the second embodiment of the above-mentioned developing roller.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com