Electrical control system of wagon shop repair wheel set suspension type axle machining assembly line

An electrical control system and assembly line technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as unformed assembly line operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

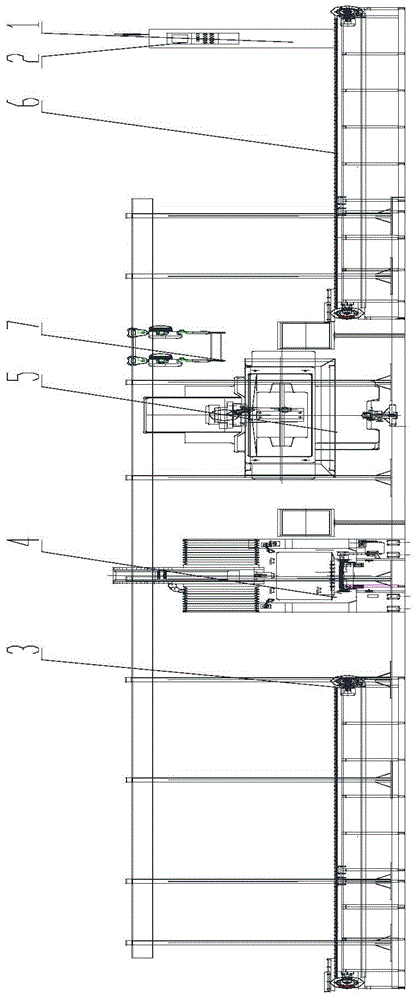

Image

Examples

Embodiment 1

[0010] Embodiment 1 The working process of the electrical control system of a wheel repairing assembly line for suspended axles in a railway freight car factory:

[0011] The present invention relates to an electrical control system for a suspension axle processing assembly line for repairing wheel pairs in a railway freight car factory. Panel 4, assembly line operation wireless remote control panel at the grinding machine 5, good axle storage line motor starter 6, double-drive electric hoist starter 7, characterized in that it is a railway wagon factory repairing wheel pair suspended axle processing line The PLC programmable controller 2 of the electric control system controls the good axle storage line motor starter 3, the assembly line operation wireless remote control panel at the lathe 4, the grinding machine assembly line operation wireless remote control control panel 5, the good axle storage line motor starter 6 , Double drive electric hoist starter 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com