Underwater production facility virtual assembly method

A virtual assembly and facility technology, applied in the field of virtual assembly, can solve the problems of single path, too many paths, and the optimal selection of different paths, etc., to achieve the effect of simple operation, simple assembly operation, and convenient assembly process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Establish relational database and track database based on Pro / E secondary development technology;

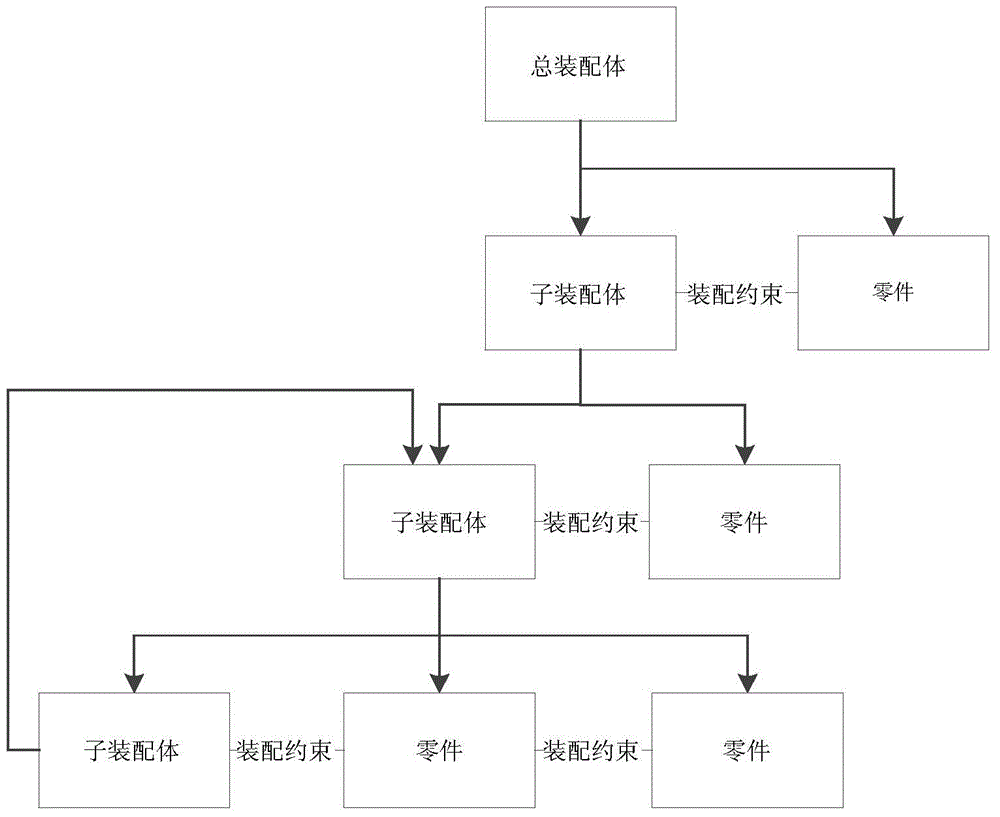

[0050] The establishment method of the relational database is as follows: split the assembly sequence and process of the assembly to form multi-level sub-assemblies and parts, establish an assembly structure tree, and enter the obtained assembly cooperation relationship and part attributes and identification into the relational database middle;

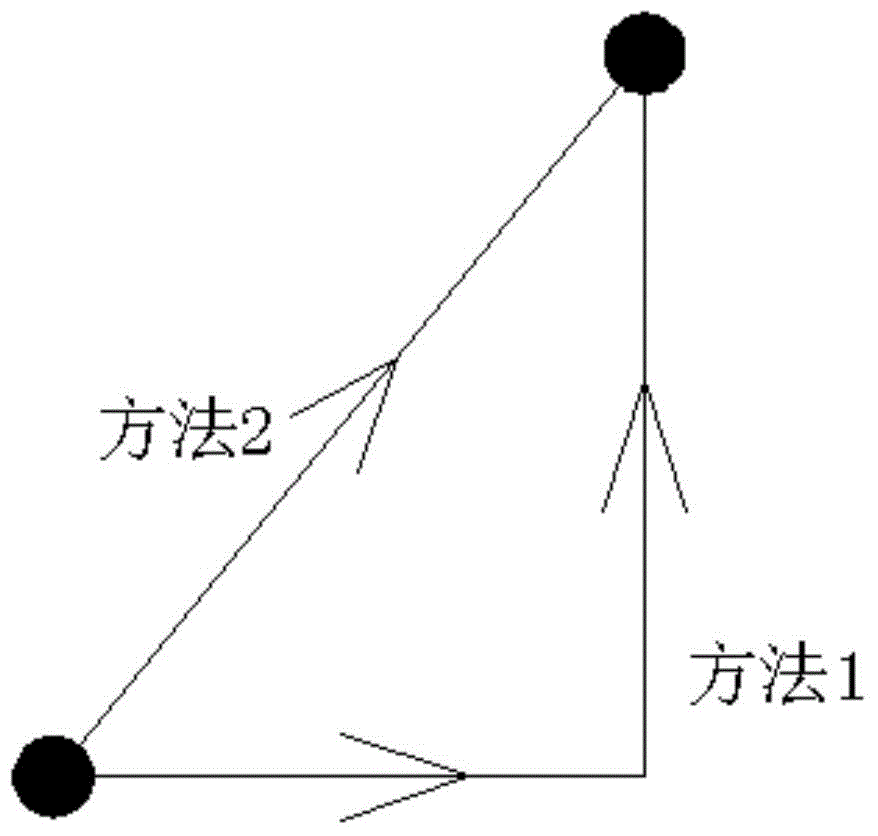

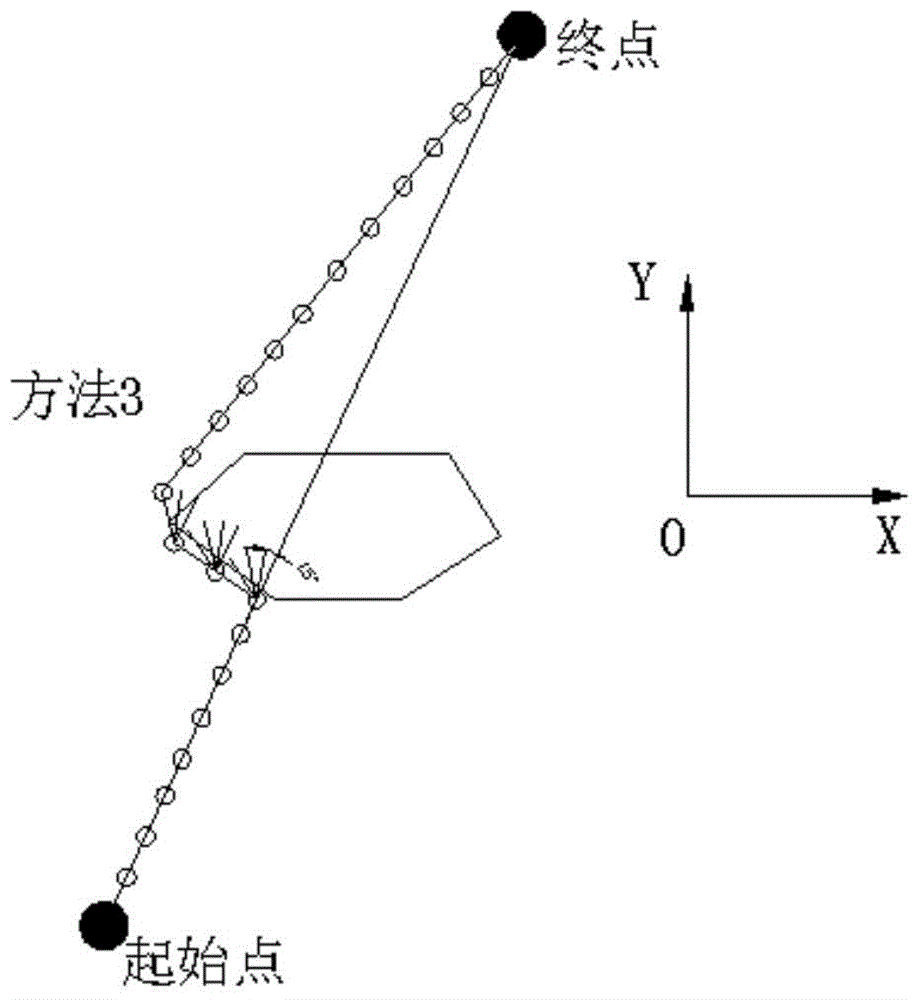

[0051] The method for establishing the trajectory database is as follows: multiple assembly displacement paths are set between the subassembly to be assembled and the parts; the path of method 1 is to move between the subassembly to be assembled and the parts at a right angle Way. The path of method 2 is to move between the sub-assembly and the part to be assembled along the path of the two-point vector direction from the beginning to the end. Method 3 is the obstacle avoidance method.

[0052] (2) Import the sub-assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com