A kind of production technology method of invisible magnetic stripe transaction card

A production process and transaction card technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of high rejection rate of finished products, low production efficiency, and high production costs, and achieve high production efficiency and supply. The effect of fast cycle and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

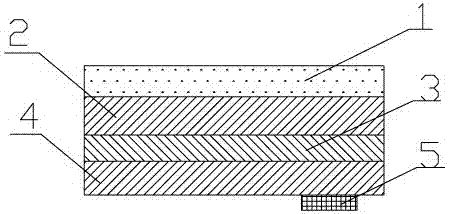

Image

Examples

Embodiment Construction

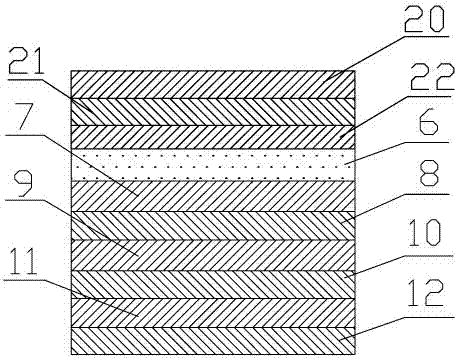

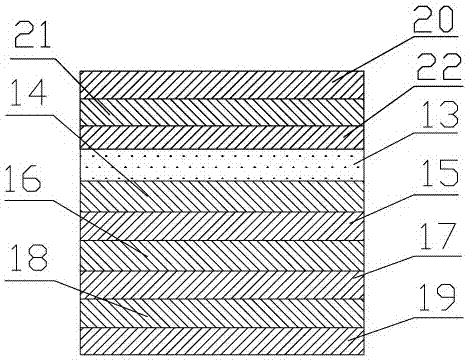

[0022] The present invention comprises following processing steps, see image 3: (1) Take the substrate layer 13 (generally PVC sheet, which can be PETG sheet and other equivalent sheets), and use a lithographic printing machine to print a special gray offset printing ink layer 14 on the inner surface of the substrate layer 13 to form the first intermediate layer. Body; the gray offset printing ink 14 is formulated from the following raw materials by weight: 46.37 kilograms of transparent color offset printing ink, 42.90 kilograms of deep black offset printing ink, 5.51 kilograms of yellow offset printing ink, and 5.22 kilograms of green offset printing ink; the gray offset printing ink is Under standard conditions, the material is accurately taken by weighing and measuring method, and then it is prepared by adding materials in strict accordance with the order of the above-mentioned raw materials; (2) the invisible magnetic strip 16 is mounted on the adhesive layer 15 with adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com