Internal-supporting amorphous alloy core

A technology of amorphous alloy and iron core, which is applied in the field of inner braced amorphous alloy iron core, can solve the problems of increased core loss and noise, increased transformer manufacturing cost, increased distance between low-voltage coils and iron core, etc., to avoid loss and noise, improve Short-circuit resistance and the effect of increasing adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

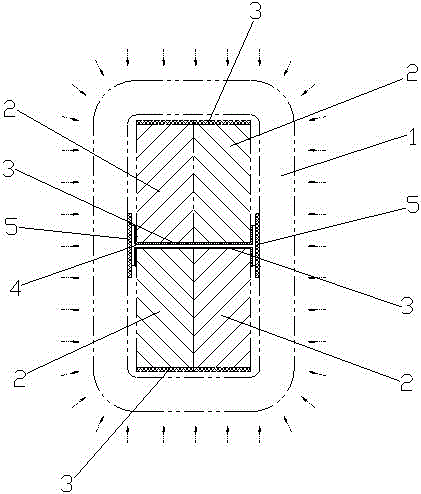

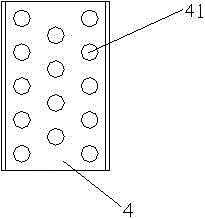

[0013] Such as figure 1 and figure 2 As shown, an inner-supported amorphous alloy iron core includes an iron core assembly, and a low-voltage coil 1 is arranged on the periphery of the iron core assembly. The iron core assembly includes an amorphous alloy iron core 2 divided into upper and lower layers, wherein the upper layer The number of the amorphous alloy core 2 and the lower amorphous alloy core 2 are two, the cross section of the amorphous alloy core 2 is rectangular, and the upper end faces of the two upper layer amorphous alloy cores 2 are provided with the two upper layers. An epoxy adhesive layer 3 for bonding the amorphous alloy cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com