Daily monitoring method for ion implantation dip angle

An ion implantation, daily technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of economical unsuitability for daily monitoring, waste of resources, etc., to achieve the effect of saving resources and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

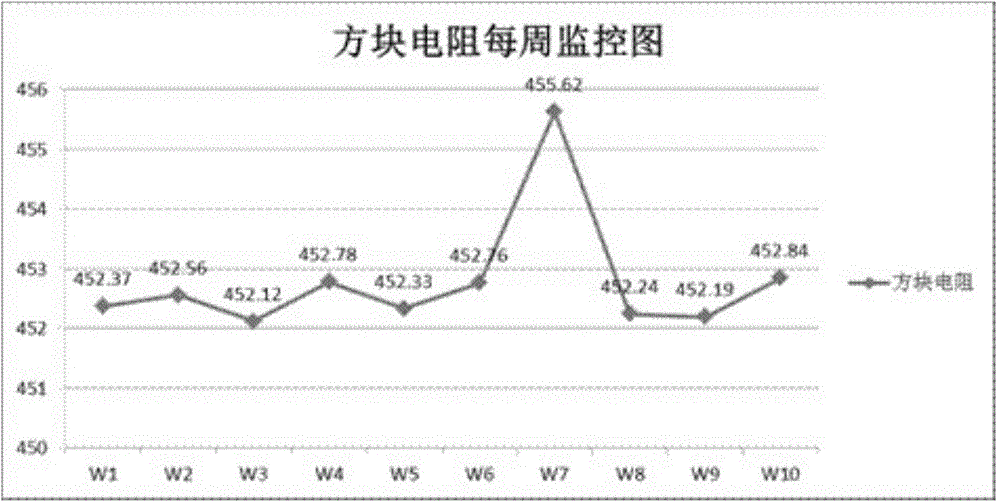

[0030] The present application relates to a daily monitoring method for ion implantation inclination, which is applied to the monitoring of semiconductor manufacturing equipment, and preferably can be applied to processes of 65 / 55nm, 45 / 40nm and other technical nodes. Through the improved monitoring method of implantation inclination, a small number of monitoring sheets can be used to achieve the effect of continuously monitoring the implantation angle of the ion implanter for a long period of time, saving material resources and reducing production costs.

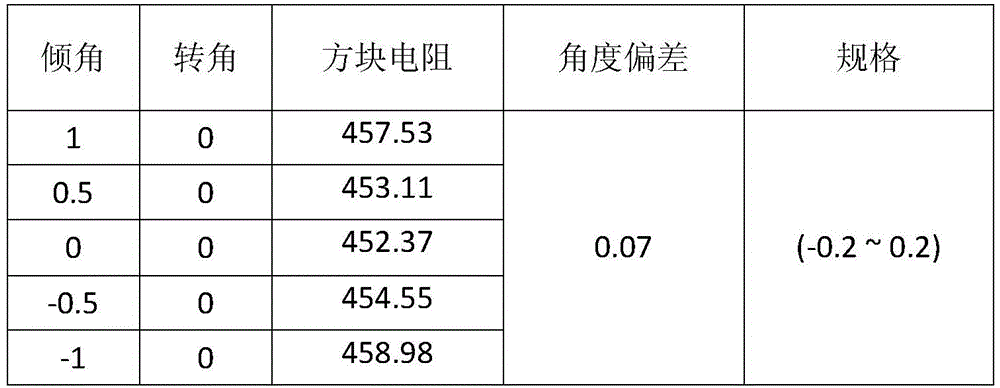

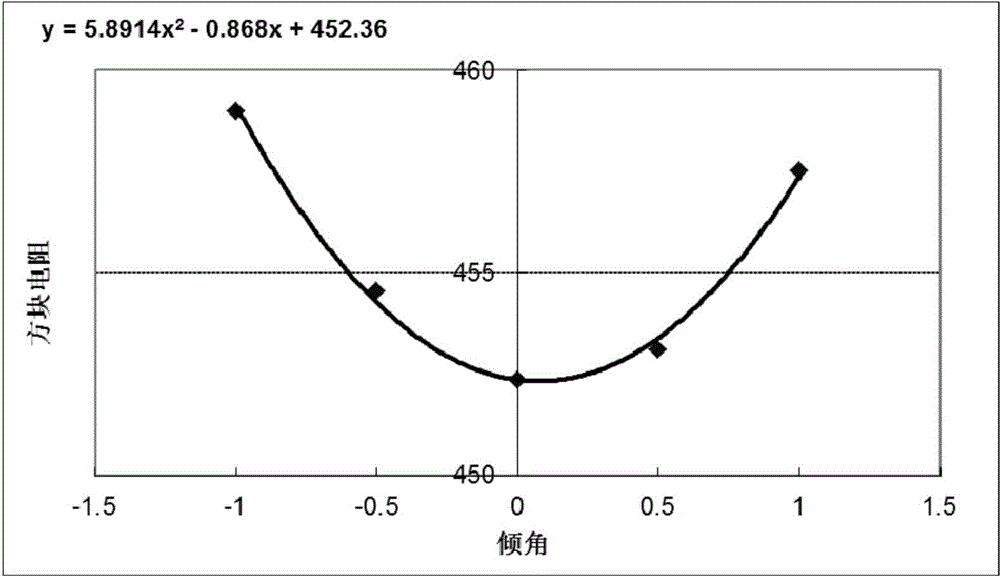

[0031] The core idea of the present invention is to use a small number of monitoring pieces to monitor the inclination angle for continuous cycles, use the long-term monitoring square resistance statistical curve to monitor the high point of the square resistance, and perform standard angle detection to confirm the angle deviation after discovery.

[0032] The specific embodiment of the present invention will be further de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com