Flip Chip Package Structure

A flip-chip packaging, electrical technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problem of consuming human resources, increasing the frequency of manual adjustment of machine identification by operators, reducing machine driving rate and production line. work efficiency and other issues, to avoid pollution or damage and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

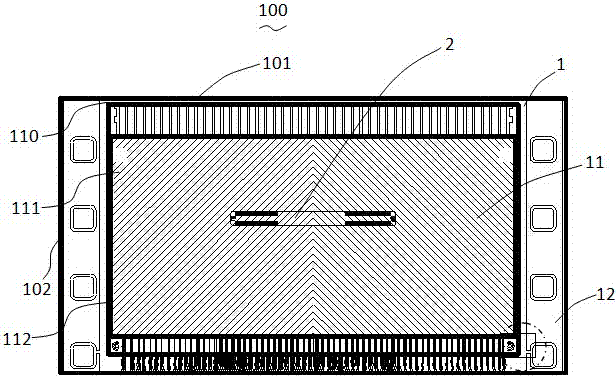

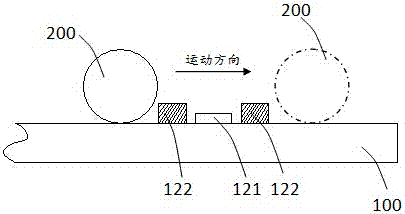

[0018] Please refer to figure 1 As shown, the present invention discloses a flip-chip packaging structure 100 , which defines that the extending direction of the long side 101 of the flip-chip packaging structure 100 is the horizontal direction, and the extending direction of the wide side 102 is the longitudinal direction. this invention figure 1 Shown is a single flip-chip packaging structure 100 , generally, several flip-chip packaging structures 100 are connected along the lateral direction and rolled up for use by panel manufacturers.

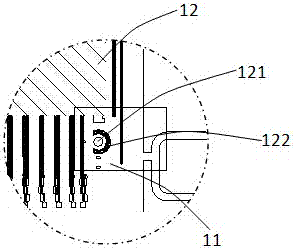

[0019] The flip-chip package structure 100 includes a flexible circuit board 1 and a chip 2 fixed on the flexible circuit board 1 . The flexible circuit board 1 is provided with an electrical functional area 11 and a non-electrical functional area 12 adjacent to the electrical functional area 11 . The electrical functional area 11 includes a base layer 110 , a circuit layer 111 disposed on the base layer 110 , and a protective layer 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com