OLED array substrate and manufacturing method thereof, packaging structure, display device

A technology of array substrate and packaging structure, which is applied in the direction of organic semiconductor devices, semiconductor devices, electrical components, etc., can solve problems such as poor cathode bonding, and achieve the effects of reducing cathode resistance, improving poor bonding, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

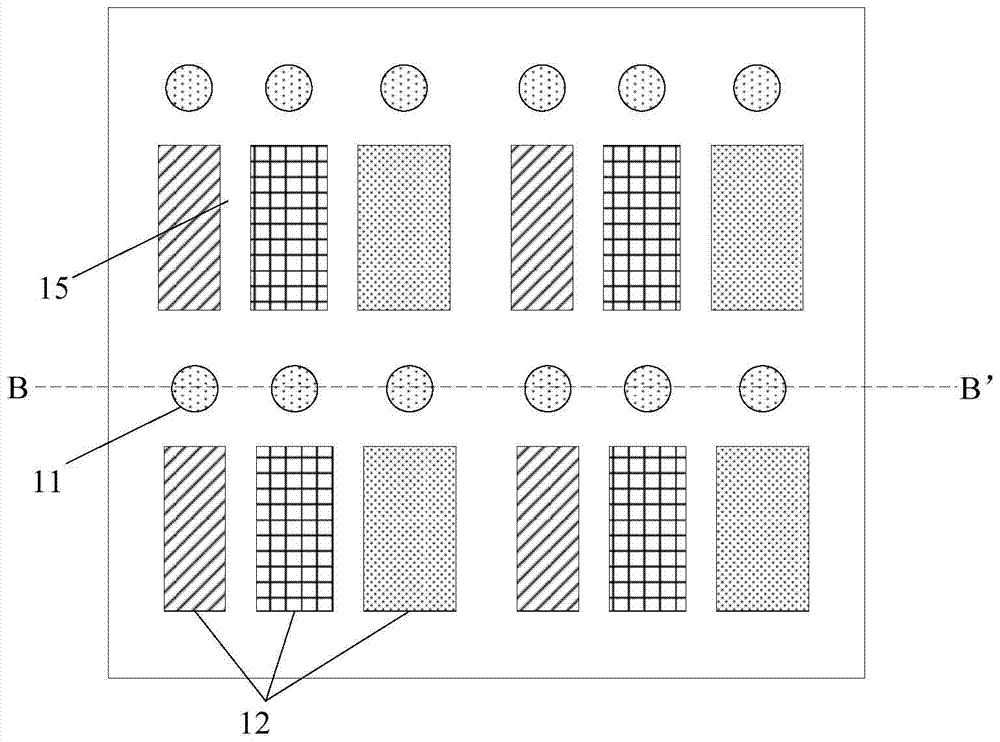

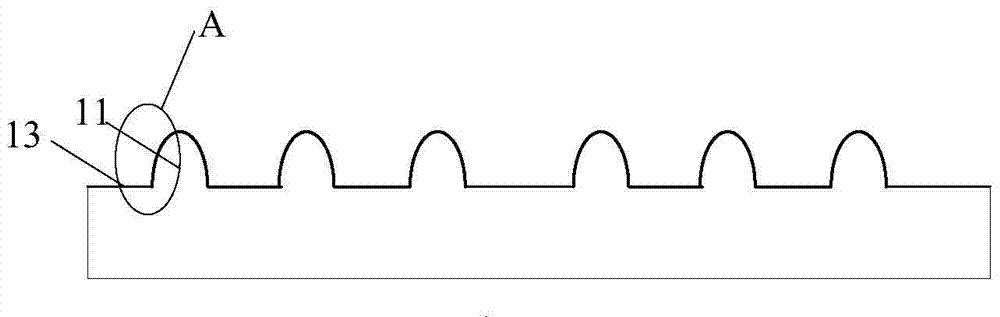

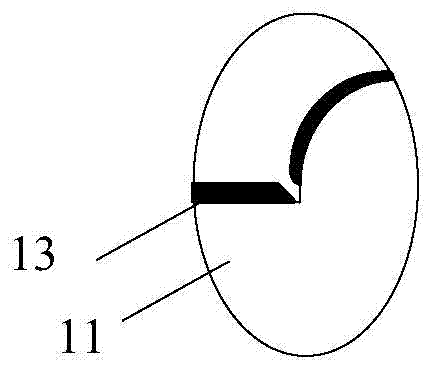

[0036] figure 1 is a schematic plan view of an existing OLED array substrate, figure 2 for figure 1 Schematic diagram of the cross-section in the direction of BB', image 3 for figure 2 An enlarged schematic view of part A in Fig.

[0037] A thin film transistor, a pixel defining layer, an anode, an organic functional layer and a cathode are formed on the OLED array substrate, and the boundary 15 of the pixel defining layer defines a plurality of sub-pixels 12 . Existing top-emitting OLED devices generally require a thinner cathode 13 to ensure higher light transmittance, but since the OLED array substrate needs to be packaged with the packaging substrate, it is also necessary to set a support box thicker on the OLED array substrate. spacer 11, the height of the spacer 11 is mainly composed of the planarization layer resin and the pixel definition layer resin formed before forming the cathode, and the cathode 13 is covered on the spacer 11. Since the spacer 11 has a cer...

Embodiment 2

[0043] The present invention also provides an OLED encapsulation structure, comprising the above-mentioned OLED array substrate and encapsulation substrate.

[0044] Wherein, the edges of the OLED array substrate and the packaging substrate are bonded and fixed by sealing glue, and the OLED packaging structure further includes a spacer for supporting the thickness of the box between the OLED array substrate and the packaging substrate , the spacer is located inside the sealant.

[0045]Since the spacer has a certain height, the OLED array substrate in the area where the spacer is placed has a large fluctuation. In this embodiment, the thickness of the cathode in the area where the spacer is located is increased without changing the thickness of the cathode in other areas. Therefore, without reducing the transmittance of the cathode in the light-emitting area, the problem of poor overlap of the cathode in the area with large fluctuations can be improved, and the resistance of t...

Embodiment 3

[0047] This embodiment also provides a display device, including the above-mentioned OLED encapsulation structure. The display device may be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com