Battery slurry preparation method

A slurry and battery technology, which is applied in the field of battery slurry preparation, can solve the problems of large differences in solid powder density, powder dust, prolonging the stirring time of stirring and dispersing equipment, etc., to achieve the effect of uniform particle size and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

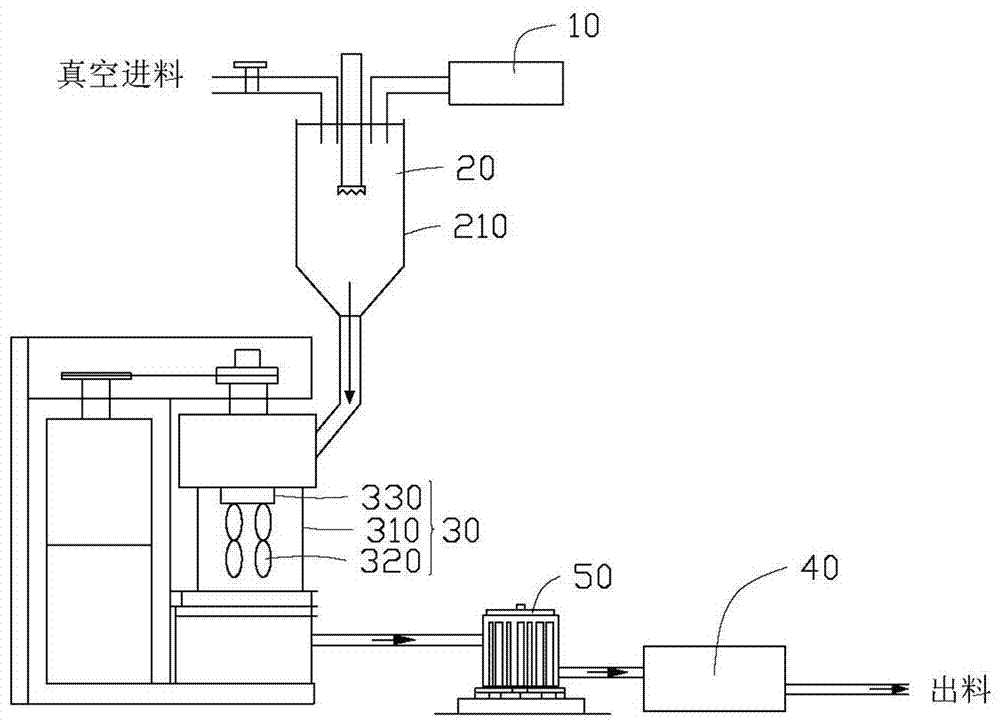

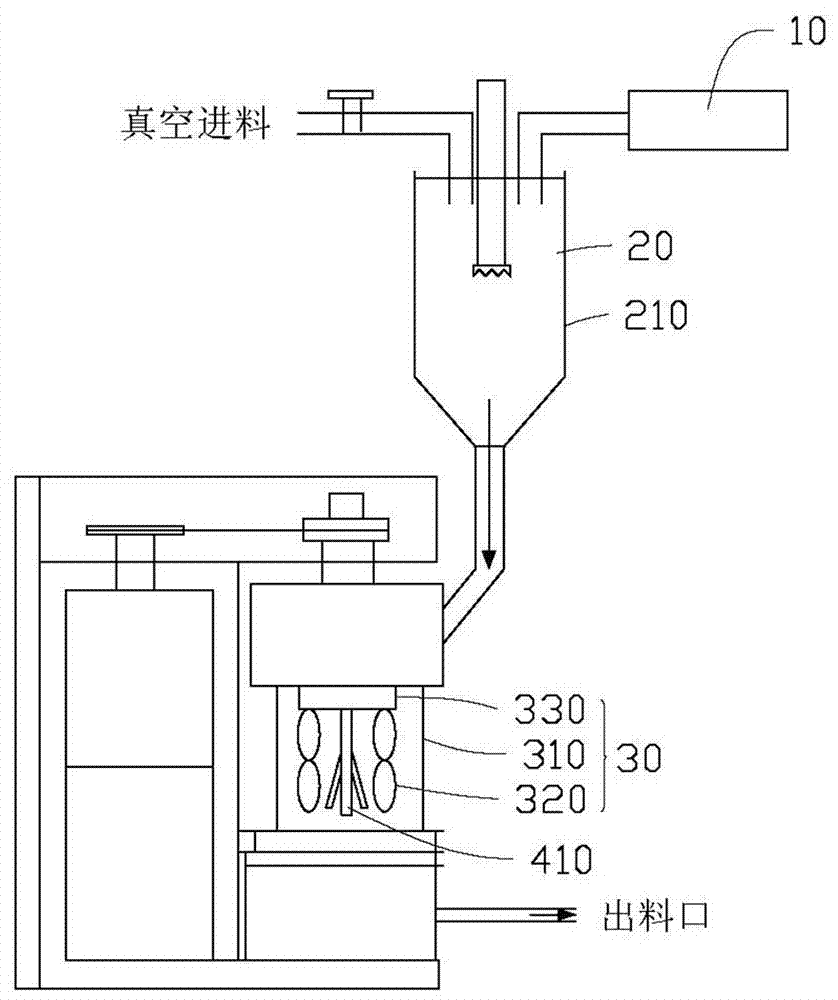

[0017] see figure 1 The embodiment of the present invention provides a battery slurry preparation equipment 1, including a vacuum system 10, a dry powder mixing device 20, a kneading device 30 and a high-speed dispersing device 40, and the dry powder mixing device 20, the kneading device 30 and the high-speed dispersing device 40 are sequentially connect.

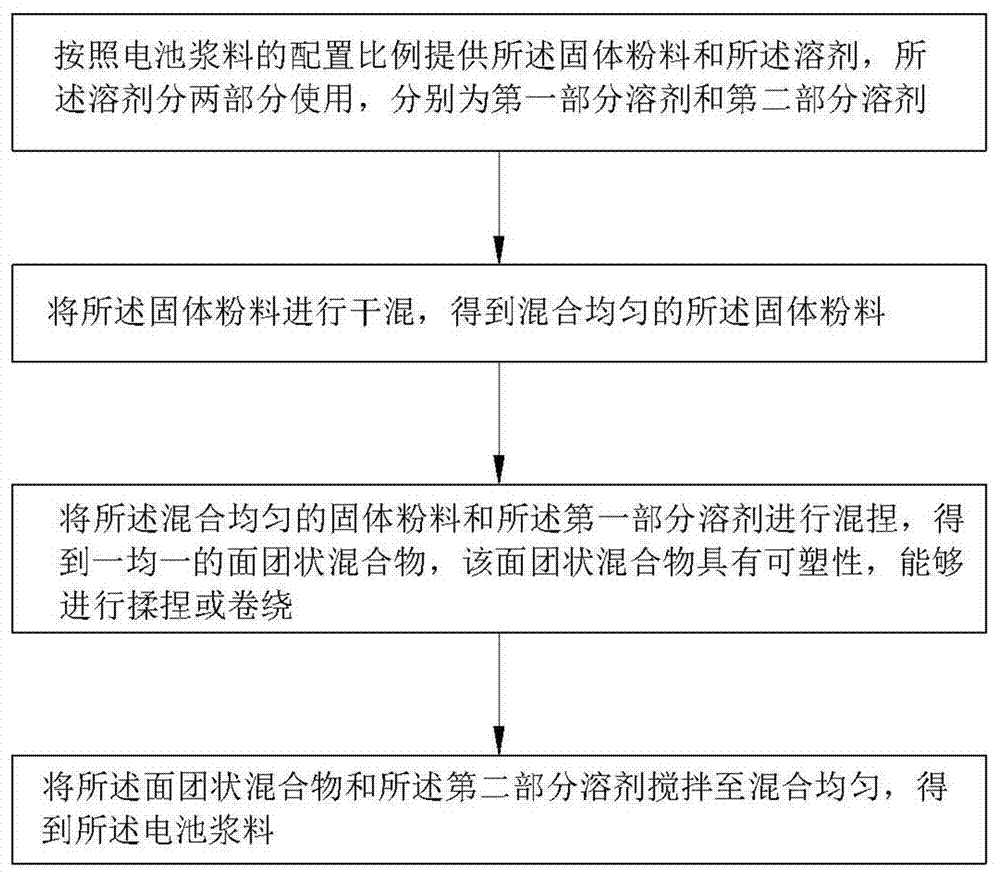

[0018] The battery slurry can be any battery slurry prepared by mixing and dispersing multi-component solid powder with a solvent, such as but not limited to lithium-ion battery electrode slurry, lead-acid battery electrode slurry or nickel Hydrogen battery electrode paste, etc. The solid powder includes all solid raw materials used to prepare the battery slurry. The solvent includes all liquid raw materials used to prepare the battery slurry. Taking lithium-ion battery electrode slurry as an example, the solid powder can include an active material, a conductive agent and a binder, the active material is a positive elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com