A kind of organic complex laser and its preparation method

A technology of organic complexes and lasers, applied in the direction of the structure of the active region, to achieve the effect of low lasing threshold, various types and structures, and large gain coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

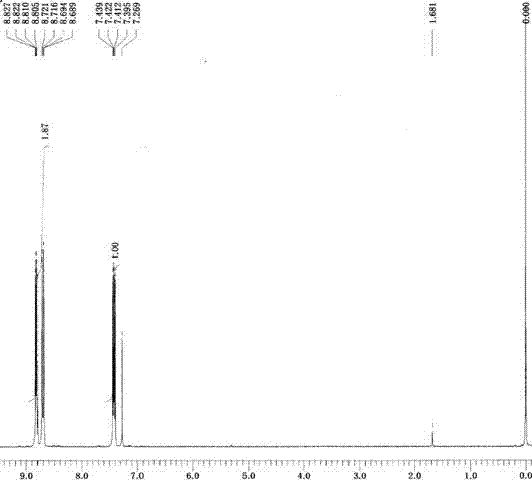

[0022] Step 1: Mix 40mL of benzene and 6mL of acetic acid to form a mixed solvent, add it to a three-necked flask, and under the protection of argon, add 1.00g of ammonium acetate (the amount of the substance is 13.0 mmol), 910mg of 4,5- Diazafluoren-9-one (the amount of the substance is 5.0 mmol) and 500 mg malononitrile (the amount of the substance is 7.5 mmol), install the water separator, heat and reflux at 80 ° C for 20 hours, cool to room temperature, and rotate The solvent was removed by evaporation, and the resulting residue was purified by chloroform column chromatography to obtain a yellow solid, which was analyzed by nuclear magnetic resonance, and the obtained spectrum was shown in figure 1 , it can be seen that the yellow solid is 9-dicyanomethylene-4,5-diazafluorene, and the yield is 61%. Melting point: 279-280 °C.

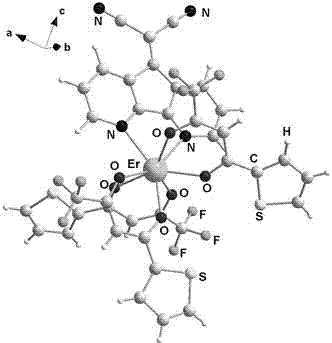

[0023] Step 2: In a one-necked bottle, dissolve 0.6 mmol Er(TTA)3·2H2O in 50 mL methanol solution, and dissolve 0.6 mmol yellow solid 9-dicyanometh...

Embodiment 2

[0027] Step 1 and step 2 are the same as in Embodiment 1.

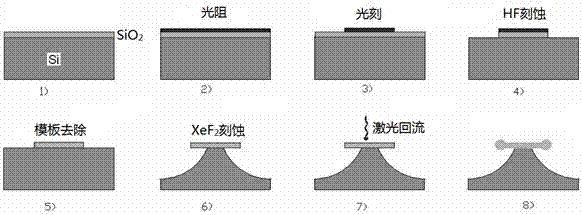

[0028] Step 3: Prepare the 9-dicyanomethylene-4,5-diazafluorene metal erbium complex into a 1.1 mmol / L tetrahydrofuran solution, and spin-coat the solution on the surface of the silicon wafer to a thickness of 10 nm thin film, and then photolithography, HF etching, XeF2 etching, CO2 laser heating and reflowing to form a silicon oxide microring core optical microcavity, the specific steps are as follows image 3 shown.

[0029] Step 4: Fabricate an organic complex laser using a silicon oxide microring core optical microcavity assembly.

[0030] Laser test example

[0031] A single-mode optical fiber with a diameter of 125 μm is heated by hydrogen combustion, and then slowly drawn into a micro-fiber with a diameter of 1-2 μm, and the loss is controlled within 5%. Then put the silicon oxide microring core optical microcavity prepared in Example 1 on the three-dimensional piezoelectric console, precisely control its po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com