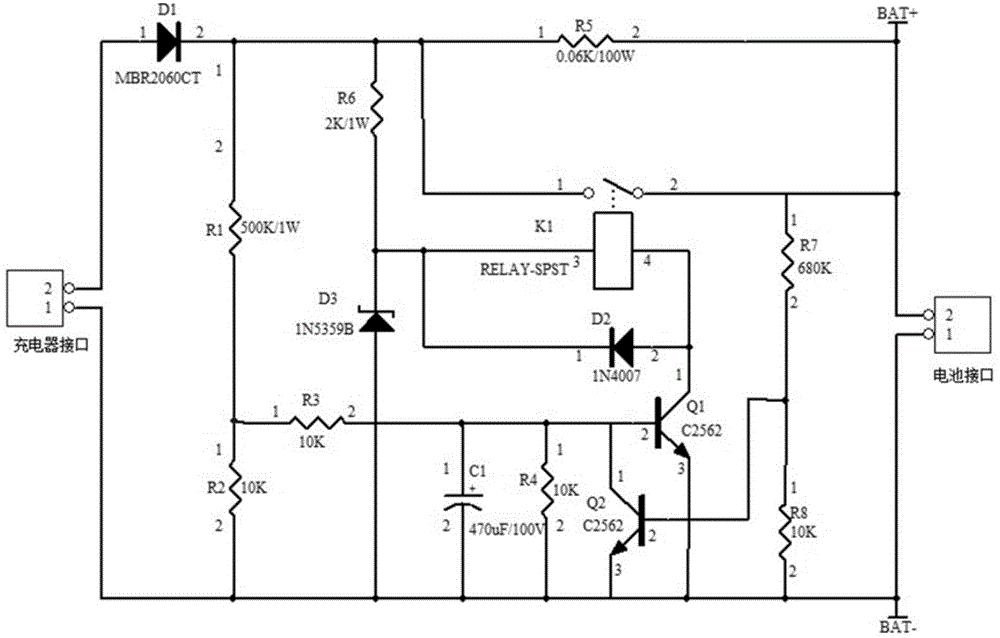

Buffer charging circuit of lithium battery

A buffer charging, lithium battery technology, applied in the field of lithium power supply, can solve the problems of large charging current, overheating, shortened lithium battery life, etc., to achieve the effect of increased discharge, improved safety, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The core idea of the technical solution is to use the time delay of the RC snubber circuit to switch and charge the lithium battery with large and small currents. When the high-current charging is fully charged, the high-current will cause the ripple of the battery voltage to increase, so that the battery is fully charged, and the charging will stop. This technical solution realizes switching between large and small currents through resistor current limiting and relay exchange, and also supplements electricity with small currents.

[0019] A lithium battery buffer charging circuit, including a charger interface, a battery interface, a charging circuit connected to the charger interface and the battery interface, a buffer timing circuit and a supplementary circuit;

[0020] The charging loop includes a diode D1, a resistor R5, a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com