Automatic repair system for power supplies

A repair system and automatic power supply technology, which is applied in the direction of emergency power supply arrangements, electrical components, circuit devices, etc., can solve problems that affect the normal use of equipment, long maintenance cycles, and high maintenance costs, so as to prevent the expansion of faults, improve flexibility, and expand Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

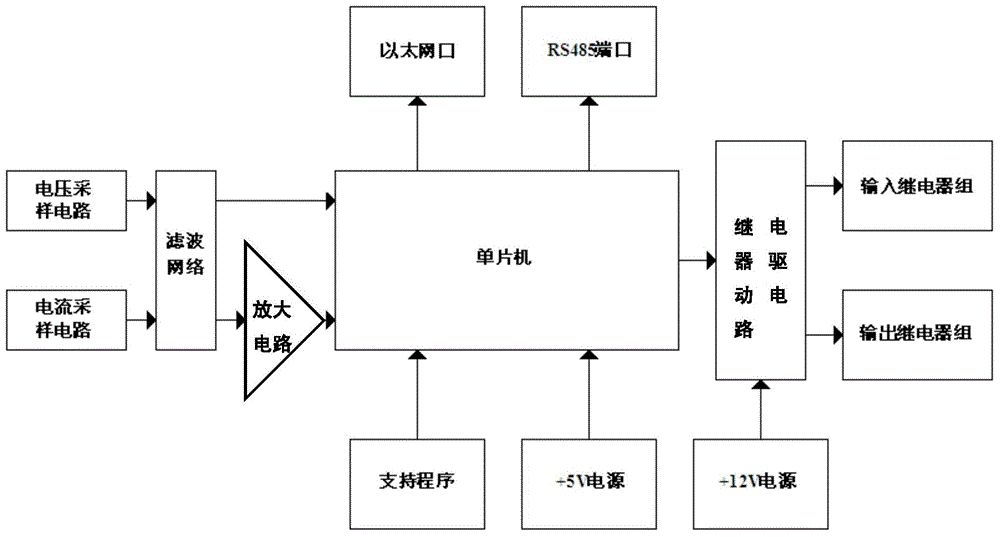

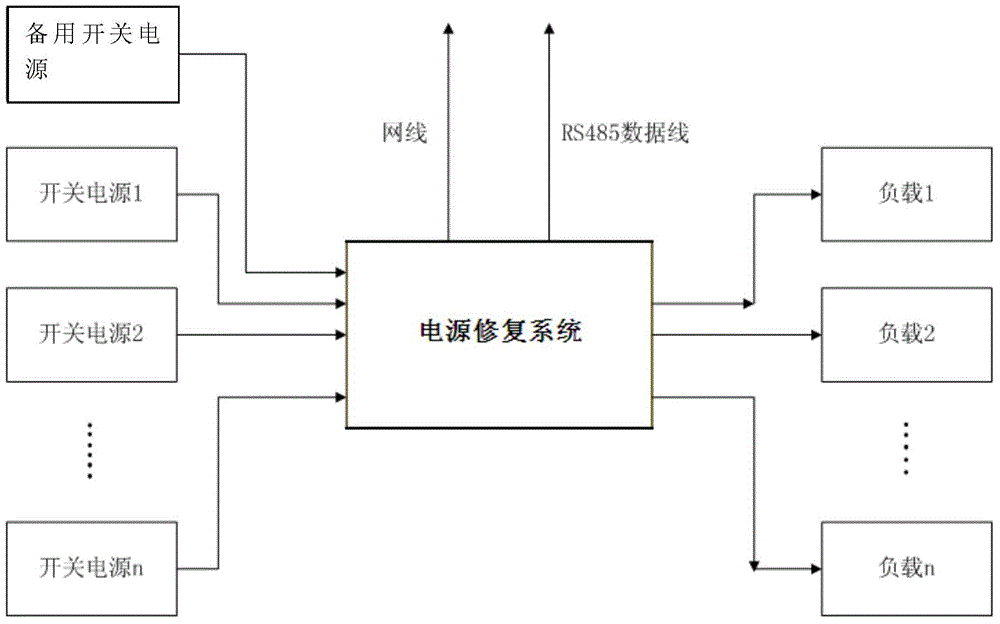

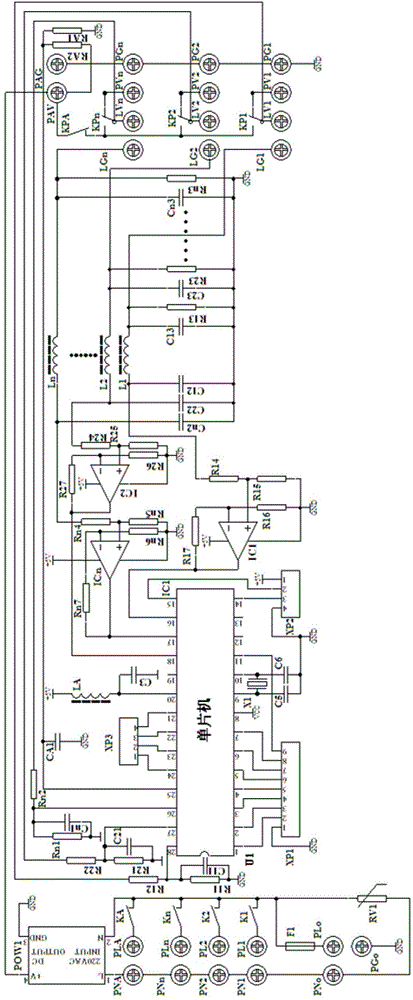

[0032] refer to Figure 1 to Figure 3 , a power supply automatic repair system, connected between a switching power supply group and a load group, including a voltage sampling circuit, a current sampling circuit, a filter network, an amplifying circuit, a main control unit, a relay group and a local power supply circuit. The switching power supply group includes n switching power supplies and one standby switching power supply, and the load group includes n loadings, n=1, 2, 3....

[0033] The voltage sampling circuit is connected with the load group and the main control unit to obtain multiple sampling voltages and then send them to the main control unit. The voltage sampling circuit uses n resistance dividers corresponding to the load group, and the nth resistance divider includes two resistors connected in series: the first divider resistor R n1 and the second divider resistor R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com